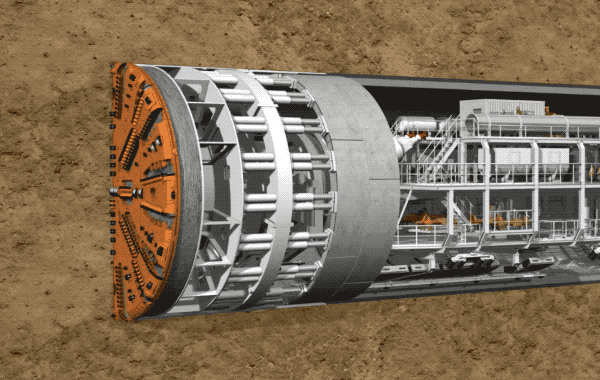

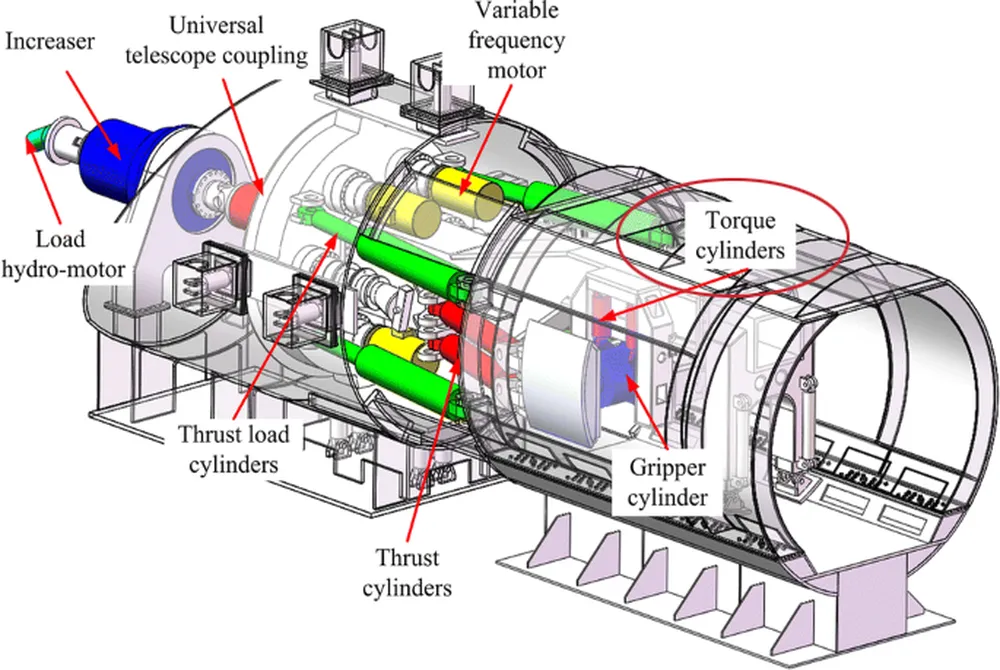

Hydraulic Cylinder for Open Tunnel Boring Machine

The Hydraulic Cylinder for Open Tunnel Boring Machines is an essential component engineered to enhance the efficiency and effectiveness of tunnel excavation processes. Designed to provide powerful thrust and precise control, these hydraulic cylinders facilitate smooth operation in demanding environments.

Key Features:

- High Performance: Capable of generating significant force, these cylinders ensure rapid and efficient tunneling, reducing project timelines and increasing productivity.

- Robust Design: Constructed from high-strength materials, the cylinders are built to withstand harsh conditions, including high pressures and abrasive environments, ensuring long-lasting durability.

- Precision Engineering: The hydraulic system allows for accurate movement and control of the boring machine, enabling precise tunneling and alignment, which is critical for successful excavation.

- Enhanced Stability: These cylinders contribute to the overall stability of the boring machine, allowing it to navigate through various geological formations without compromising safety.

- Versatile Applications: Suitable for a wide range of projects, including subways, utility tunnels, and infrastructure development, these cylinders are adaptable to different tunneling needs.

- Minimal Maintenance: The durable construction reduces wear and tear, leading to lower maintenance costs and minimizing downtime, which enhances overall project efficiency.

- Safety Mechanisms: Equipped with advanced safety features, these hydraulic cylinders help prevent accidental disengagement, ensuring secure and reliable operation during excavation.

The Hydraulic Cylinder for Open Tunnel Boring Machines is a crucial asset in modern tunneling technology, delivering high performance, reliability, and safety. Its integration into tunnel boring machines significantly enhances the efficiency of underground construction projects, contributing to the successful completion of essential infrastructure.

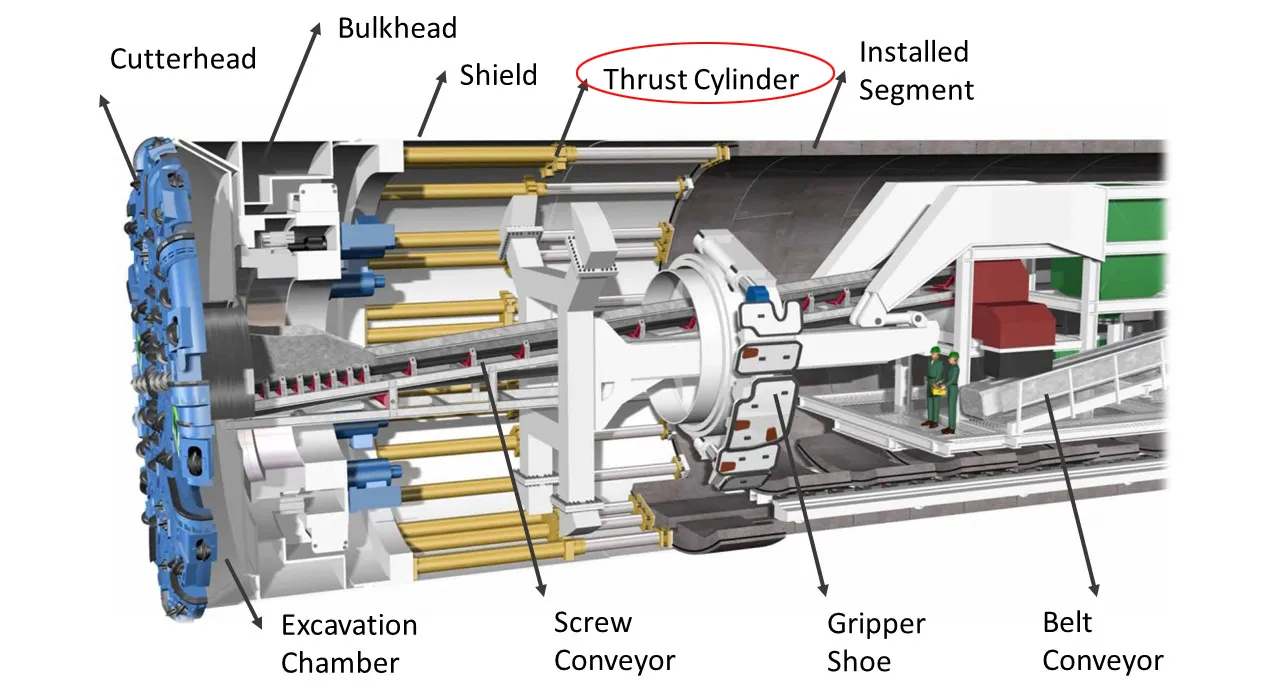

Open Tunnel Boring Machine Support Shoe Cylinder

| Product Name | Open Tunnel Boring Machine Support Shoe Cylinder |

| Features: | Provides the thrust of cutterhead tunneling |

| Bore diameter: | 480mm~1000mm |

| Rod diameter: | 400mm~730mm Stroke400mm~825mm |

| Pressure: | up to 35MPa |

| Applications: | Open Tunnel Boring Machine |

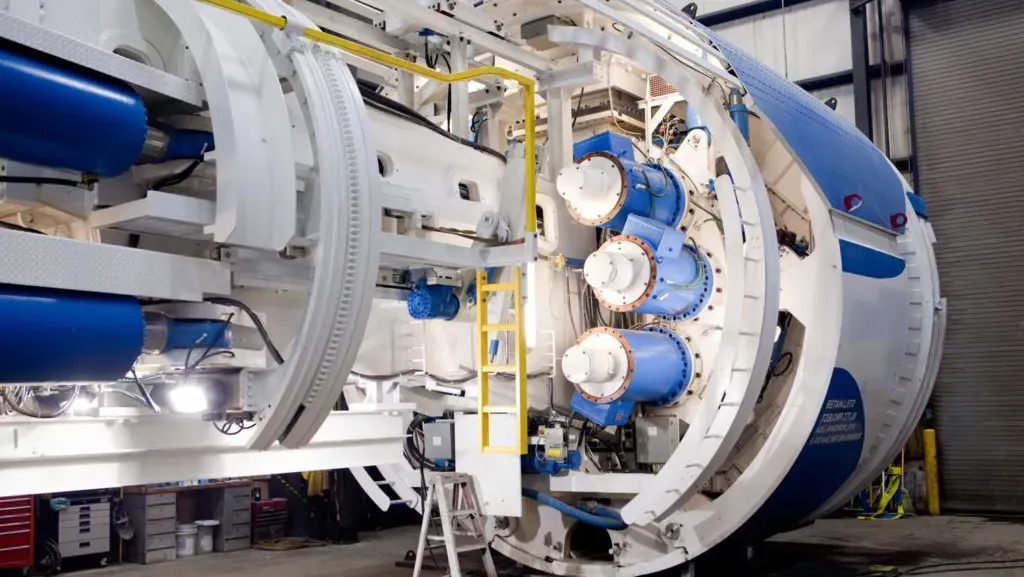

Open Tunnel Boring Machine Thrust Cylinder

Open Tunnel Boring Machine Thrust Cylinder

| Product Name | Open Tunnel Boring Machine Thrust Cylinder |

| Features: | Provide the thrust of tunnel boring machine forward tunneling |

| Bore diameter: | 300mm~600mm |

| Rod diameter: | 200mm~400mm Stroke1100mm~2050mm |

| Pressure: | up to 35MPa |

| Applications: | Open Tunnel Boring Machine |

Open Tunnel Boring Machine Torque Cylinder

Open Tunnel Boring Machine Torque Cylinder

| Product Name | Open Tunnel Boring Machine Torque Cylinder |

| Features: | Used for tunnel boring machine direction adjustment and transmission of cutter head torque |

| Bore diameter: | 220mm~450mm |

| Rod diameter: | 125mm~260mm Stroke 200mm~260mm |

| Pressure: | up to 35MPa |

| Applications: | Open Tunnel Boring Machine |

Open Tunnel Boring Machine Shield Cylinder

| Product Name | Open Tunnel Boring Machine Shield Cylinder |

| Features: | Stabilize the cutter head/prevent the jamming caused by convergence |

| Bore diameter: | 130mm~360mm |

| Rod diameter: | 80mm~220mm Stroke100mm~420mm |

| Pressure: | up to 25MPa Special requirements up to 35Mpa |

| Applications: | Open Tunnel Boring Machine |

Advantages of Open Tunnel Boring Machine Hydraulic Cylinder

Advantages of Open Tunnel Boring Machine Hydraulic Cylinder

- High Thrust Capacity:

Open Tunnel Boring Machine hydraulic cylinders are designed to deliver powerful thrust, enabling rapid excavation and efficient tunneling operations. This capacity allows for quicker project completion and improved productivity. - Durable Construction:

Made from high-strength materials, these hydraulic cylinders are built to withstand harsh conditions and extreme pressures, ensuring long-term reliability and reducing the risk of failure during operation. - Precision Control:

The hydraulic system provides precise movement and control of the boring machine, allowing for accurate tunneling and alignment. This precision is essential for maintaining the integrity of the tunnel and meeting project specifications. - Enhanced Stability:

These cylinders contribute to the overall stability of the boring machine, allowing it to navigate through various geological formations without compromising safety. This stability reduces the risk of accidents and operational disruptions. - Reduced Maintenance Requirements:

The robust design minimizes wear and tear, leading to lower maintenance costs and less downtime. This efficiency ensures that the boring machine remains operational for longer periods, enhancing overall project efficiency. - Versatility in Applications:

Suitable for a variety of tunneling projects, including subways, water conveyance systems, and utility tunnels, these hydraulic cylinders are adaptable to different needs, making them a valuable asset in various construction environments. - Safety Features:

Equipped with advanced safety mechanisms, the hydraulic cylinders help prevent accidental disengagement, ensuring secure and reliable operation during demanding excavation tasks. This enhances the safety of both operators and equipment. - Compact Design with High Power Output:

The hydraulic design allows for substantial force generation in a compact form, making it easier to manage heavy loads and complex movements without increasing the machine’s overall size.

By leveraging these advantages, Open Tunnel Boring Machine hydraulic cylinders play a critical role in the efficiency, safety, and success of modern tunneling projects. Their performance and reliability are key to achieving effective underground construction.

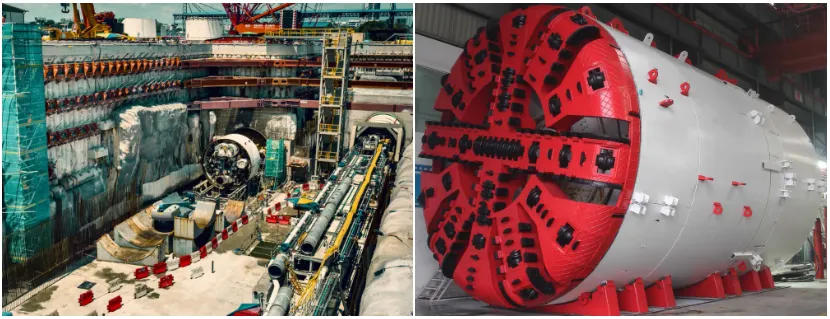

Application of Open Tunnel Boring Machine Hydraulic Cylinder

Open Tunnel Boring Machine (OTBM) hydraulic cylinders are integral to various underground excavation projects, offering versatility and efficiency in their applications. Here are some key applications:

- Subway Construction:

Hydraulic cylinders are used to excavate tunnels for subway systems, allowing for the rapid and safe creation of underground transit routes in urban areas. - Utility Tunneling:

These cylinders facilitate the installation of essential utility lines, such as water, gas, and electricity, by enabling the creation of tunnels that house these services underground. - Sewer and Drainage Systems:

OTBM hydraulic cylinders are employed in the construction of sewer and drainage tunnels, ensuring effective waste management and stormwater control in urban environments. - Underground Storage Facilities:

They are used in the excavation of tunnels for underground storage, such as fuel depots or data centers, providing a secure environment for sensitive materials. - Mining Operations:

Hydraulic cylinders play a crucial role in tunneling for mining operations, enabling the extraction of minerals and resources from beneath the earth’s surface. - Transportation Tunnels:

These cylinders are used in the construction of transportation tunnels, including those for vehicles and railways, ensuring safe and efficient passage through mountainous or urban terrains. - Infrastructure Development:

OTBM hydraulic cylinders contribute to various infrastructure projects, including the construction of underground parking facilities and basements for buildings. - Environmental Projects:

They are also utilized in projects aimed at environmental remediation, such as creating tunnels for groundwater management or contaminated site clean-up.

By supporting these diverse applications, Open Tunnel Boring Machine hydraulic cylinders enhance the efficiency, safety, and effectiveness of modern underground construction projects. Their role is crucial in facilitating the development of essential infrastructure and services.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX