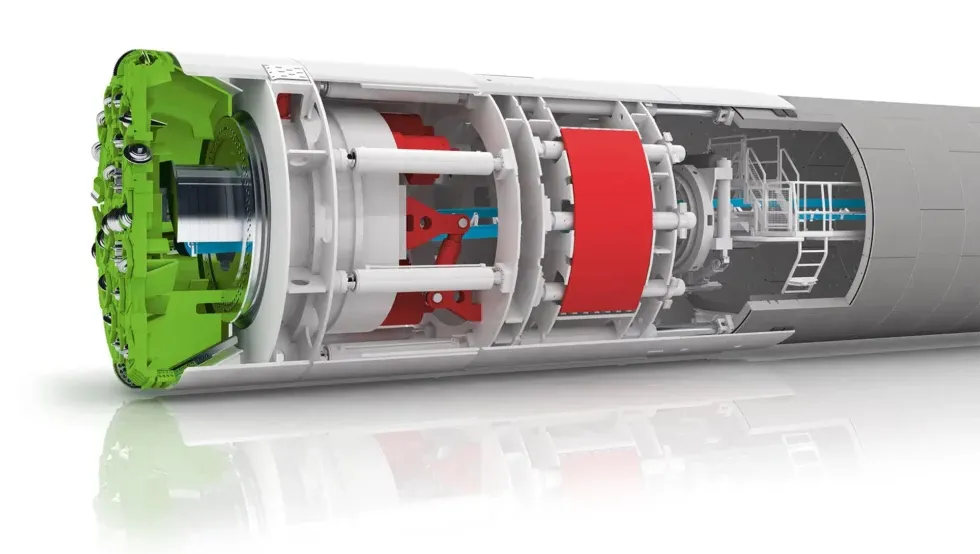

Hydraulic Cylinder for Double Shield Tunnel Boring Machine

The Hydraulic Cylinder for Double Shield Tunnel Boring Machines is an essential component designed to enhance the efficiency and precision of tunnel excavation. This advanced hydraulic system enables effective operation within the unique dual-shield framework, allowing simultaneous tunneling and support installation.

Key Features:

- High Thrust Capacity:

Engineered to deliver substantial force, these hydraulic cylinders facilitate rapid excavation, significantly reducing project timelines and improving overall productivity. - Robust Durability:

Constructed from high-strength materials, the cylinders are built to withstand the harsh conditions encountered in tunneling, ensuring long-lasting performance and reliability. - Precision Control:

The hydraulic system allows for precise movement and control of the boring machine, enabling accurate alignment and tunneling, which is critical for meeting project specifications and safety standards. - Enhanced Stability:

These cylinders contribute to the overall stability of the double shield system, ensuring secure operation through various geological formations and minimizing the risk of accidents. - Versatile Applications:

Suitable for a wide range of projects, including metro systems, utility tunnels, and infrastructure developments, these hydraulic cylinders are adaptable to various tunneling needs. - Low Maintenance Requirements:

The durable design reduces wear and tear, leading to lower maintenance costs and less downtime, which enhances overall project efficiency. - Advanced Safety Features:

Equipped with safety mechanisms to prevent accidental disengagement, these hydraulic cylinders ensure secure operation, protecting both the crew and the machinery during excavation.

The Hydraulic Cylinder for Double Shield Tunnel Boring Machines is a vital component in modern tunneling technology, providing high performance, durability, and safety. Its integration into tunnel boring machines significantly enhances the efficiency and success of underground construction projects, making it indispensable for infrastructure development.

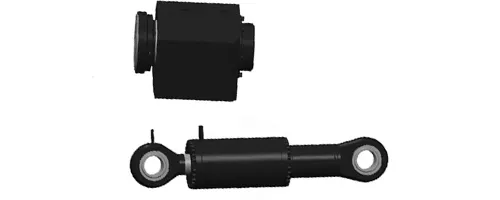

Double Shield Tunnel Boring Machine Support Shoe Cylinder

| Product Name | Double Shield Tunnel Boring Machine Support Shoe Cylinder |

| Features: | Provides the thrust of cutterhead tunneling |

| Bore diameter: | 320mm~700mm |

| Rod diameter: | 220mm~500mm Stroke: 300mm~1200mm |

| Pressure: | up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield Tunnel Boring Machine Torque Cylinder

| Product Name | Double Shield Tunnel Boring Machine Torque Cylinder |

| Features: | Transmit the torque of the cutter head |

| Specification: | Various structures and specifications of torque cylinders can be designed and produced according to customer requirements |

| Pressure: | up to 25MPa Special requirements up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield Tunnel Boring Machine Main Thrust Cylinder

| Product Name | Double Shield Tunnel Boring Machine Main Thrust Cylinder |

| Features: | Provide the thrust of TBM forward tunneling |

| Bore diameter: | 220mm~380mm |

| Rod diameter: | 150mm~280mm Stroke: 1100mm~1700mm |

| Pressure: | up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield Tunnel Boring Machine Auxiliary Thrust Cylinder

| Product Name | Double Shield Tunnel Boring Machine Auxiliary Thrust Cylinder |

| Features: | Relying on the reaction force of the auxiliary push cylinder to push the tube piece to make the TBM move forward |

| Bore diameter: | 220mm~320mm |

| Rod diameter: | 180mm~240mm Stroke: 2100mm~2600mm |

| Pressure: | up to 35MPa Special requirements up to 45MPa |

| Applications: | Double Shield Tunnel Boring Machine |

How Does the Double Shield Tunnel Boring Machine Hydraulic Cylinder Work?

The hydraulic cylinder in a Double Shield Tunnel Boring Machine (TBM) plays a crucial role in the tunneling process. Here’s an overview of its operation:

- Hydraulic Power Generation:

The hydraulic system generates power by using hydraulic fluid, which is pressurized through hydraulic pumps. This pressurization creates the force that is transmitted to the hydraulic cylinders. - Thrust Generation:

The hydraulic cylinder converts hydraulic fluid energy into mechanical energy, providing thrust to the TBM. This thrust pushes the machine forward into the rock or soil, enabling effective excavation. - Dual Shield Mechanism:

In a double shield TBM, there are two shields: the front shield (cutting shield) and the rear shield (support shield). Hydraulic cylinders are integrated into both shields, allowing for simultaneous excavation and support installation. - Cutting Head Operation:

The hydraulic cylinders control the movement of the cutting head at the front of the TBM. By extending and retracting, they help position the cutting tools to effectively break through the ground.

- Support Installation:

As the machine advances, the rear shield utilizes hydraulic cylinders to install support structures (such as segments or liners) behind the cutting head, ensuring tunnel stability during excavation. - Feedback Control:

The hydraulic system is equipped with sensors and control systems that monitor the pressure and position of the hydraulic cylinders. This feedback allows for precise adjustments, ensuring optimal performance and safety. - Stability and Safety:

The hydraulic cylinders contribute to the overall stability of the TBM, helping maintain alignment and balance, which reduces the risk of accidents and operational disruptions. - Adaptability:

The hydraulic system can be adjusted to accommodate different soil types and geological conditions, making it versatile for various tunneling projects.

Through effective management of thrust, stability, and support, the hydraulic cylinders in a Double Shield Tunnel Boring Machine are essential for successful and safe tunnel excavation, enhancing the efficiency and reliability of modern underground construction.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX