Hydraulic Cylinder for Shield Machine

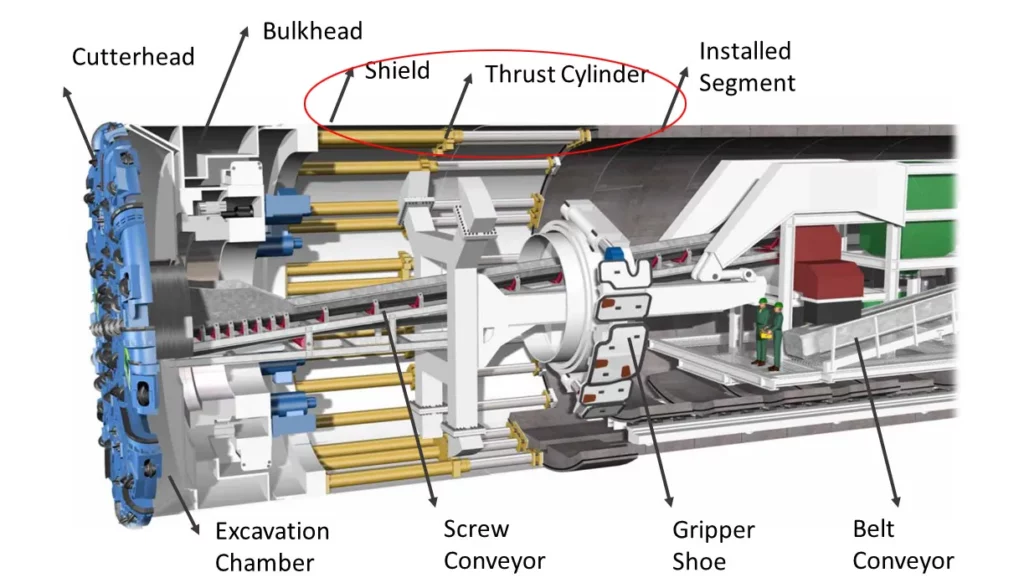

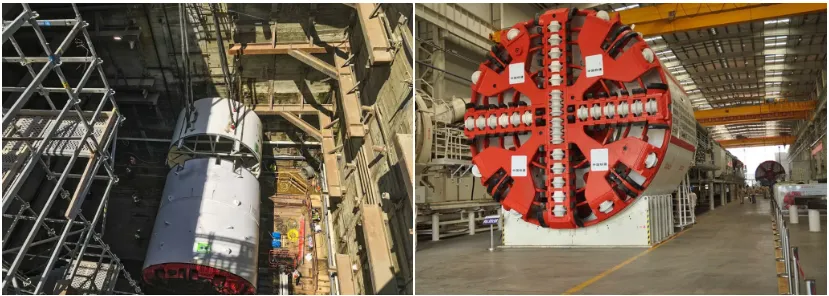

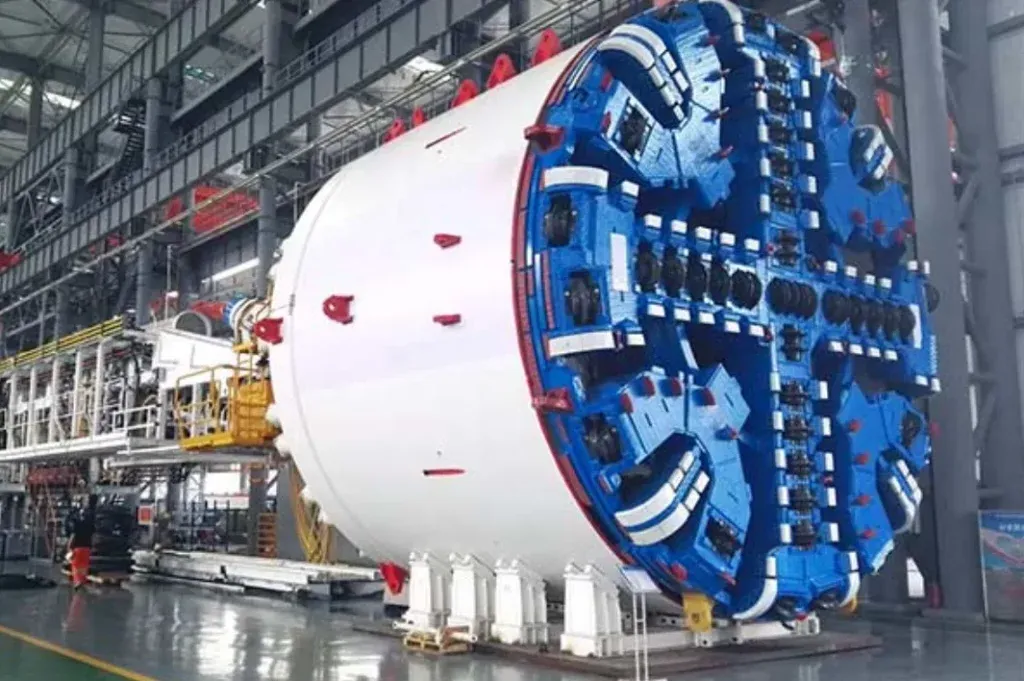

The Hydraulic Cylinder for Shield Machines is an essential component designed specifically for tunnel boring applications. Engineered to deliver high-performance thrust and support, these cylinders play a crucial role in the efficient operation of shield machines used in underground excavation.

Key Features:

- High Pressure Resistance: Built to withstand extreme pressures, these hydraulic cylinders ensure reliable performance even in challenging geological conditions.

- Durable Construction: Crafted from high-strength materials, they are designed to endure harsh environments, providing longevity and reducing maintenance needs.

- Precision Movement: The hydraulic cylinders facilitate accurate and controlled movements of the shield, allowing for effective tunneling and alignment within the bore.

- Stability and Support: They contribute significantly to the overall stability of the shield machine, enabling it to navigate various soil types and maintain operational integrity.

- Versatile Applications: Suitable for various tunneling projects, these cylinders are ideal for constructing subways, sewer systems, and other underground infrastructure.

The Hydraulic Cylinder for Shield Machines is a vital asset in modern tunneling technology, ensuring safe, efficient, and effective excavation processes. Its robust design and high-performance capabilities make it an indispensable component for successful underground projects.

Shield Machine Thrust Cylinder

| Product Name | Shield Machine Thrust Cylinder |

| Features: | Move the shield machine forward |

| Bore diameter: | 140mm~550mm |

| Rod diameter: | 120mm~420mm Stroke: 900mm~4100mm |

| Pressure: | up to 35Mpa Special requirements can reach up to 45Mpa |

| Applications: | Shield Machine, Tunnel Boring Machinery |

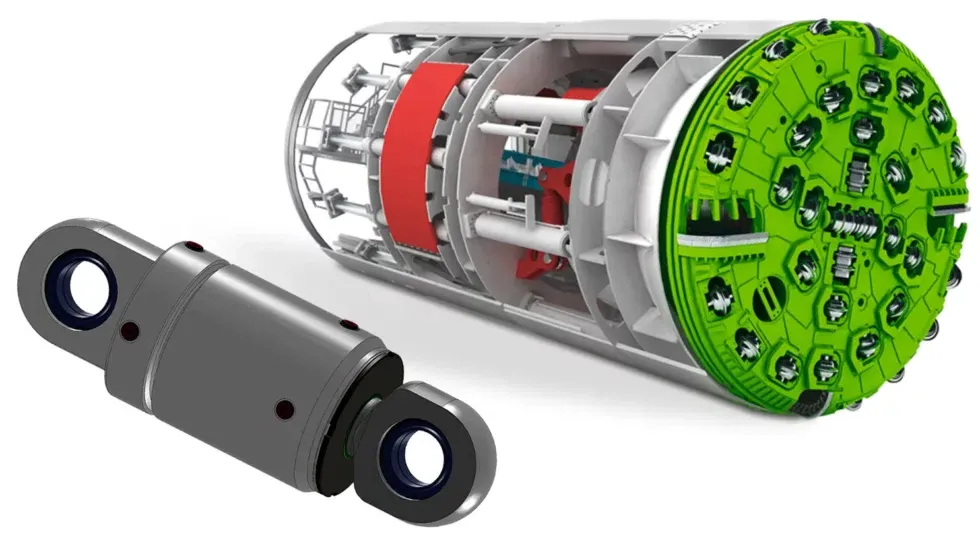

Shield Machine Articulated Cylinder

Shield Machine Articulated Cylinder

| Product Name | Shield Machine Articulated Cylinder |

| Features: | Active articulation: cutter head steering/coordinated tool change Passive articulation: drag the tail of the shield forward |

| Bore diameter: | 125mm~550mm |

| Rod diameter: | 70mm~370mm Stroke140mm~1200mm |

| Pressure: | Up to 35MPa |

| Applications: | Shield Machine, Tunnel Boring Machinery |

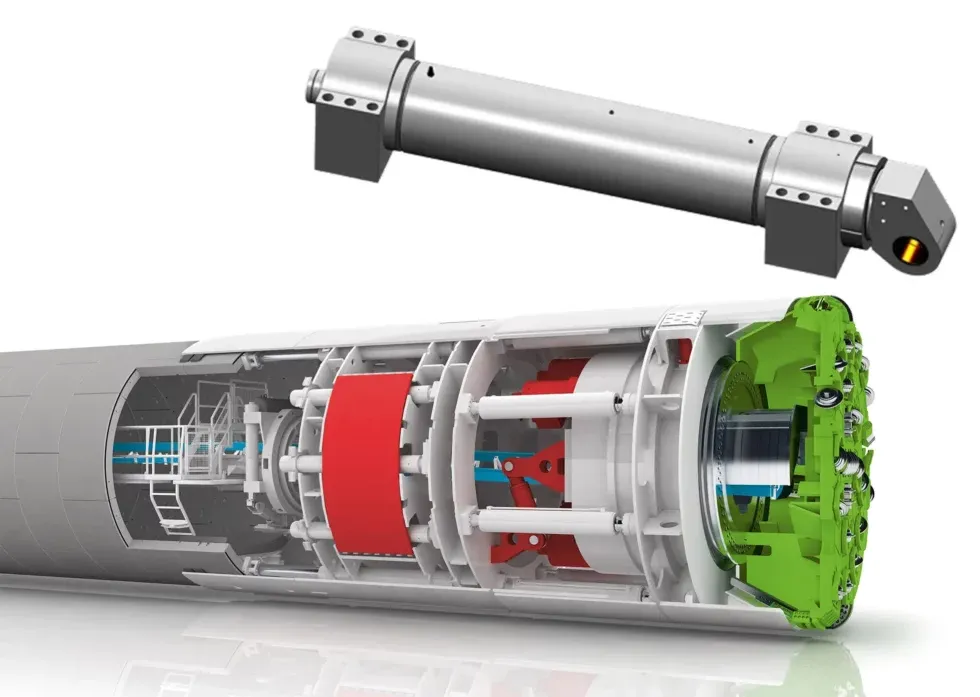

Shield Machine Assembly Lifting Cylinder

| Product Name | Shield Machine Assembly Lifting Cylinder |

| Features: | Transport the segments to the designated position and assemble them into a ring |

| Specification: | Generally two-level structure Thrust and pull are provided by the internal small oil cylinder Small piston rod fixed Large piston rods can withstand large lateral forces when telescoping |

| Applications: | Shield Machine, Tunnel Boring Machinery |

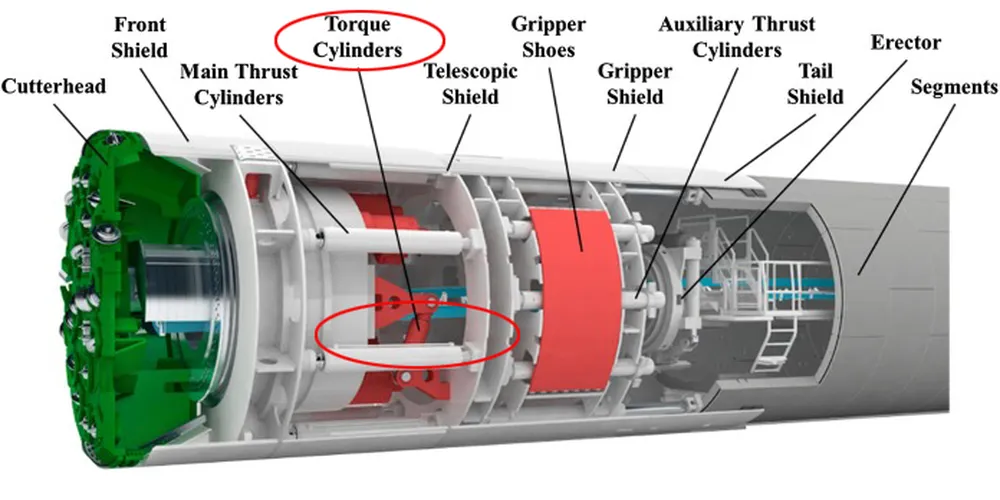

Shield Machine Anti-torque Cylinder

Shield Machine Anti-torque Cylinder

| Product Name | Shield Machine Anti-torque Cylinder |

| Features: | Transmit the torque when the cutter head rotates |

| Bore diameter: | 330mm~570mm |

| Rod diameter: | 260mm~530mm Stroke120mm~160mm |

| Pressure: | Generally up to 35Mpa Maximum up to42MPa |

| Applications: | Shield Machine, Tunnel Boring Machinery |

Shield Machine Crusher Cylinder

| Product Name | Shield Machine Crusher Cylinder |

| Features: | Clamp the crushing tongs to ensure that large pieces of gravel are crushed before they enter the discharge port |

|

Specification:

|

Various specifications of crusher cylinders can be designed and produced according to customer requirements |

| Applications: | Shield Machine, Tunnel Boring Machinery |

Advantages of Shield Machine Hydraulic Cylinder

- High Efficiency:

Shield machine hydraulic cylinders are engineered to deliver powerful thrust, which significantly enhances the speed and efficiency of tunneling operations. This capability allows construction teams to complete projects more quickly, thereby reducing overall project timelines. With faster excavation rates, contractors can meet deadlines more effectively, leading to increased productivity and cost savings. - Robust Durability:

These hydraulic cylinders are constructed from high-strength materials specifically designed to withstand harsh environmental conditions and extreme pressures encountered during tunneling. Their robust durability ensures long-term reliability, minimizing the risk of failures that could lead to costly delays. This resilience makes them suitable for various geological formations, ensuring consistent performance throughout the project lifecycle. - Precision Control:

The hydraulic system in shield machine cylinders enables highly precise movement of the shield, which is essential for accurate tunneling and alignment. This precision is crucial for successful excavation, as it allows operators to navigate complex underground environments with confidence. The ability to control fine movements reduces the risk of misalignment and ensures that the tunnel meets specified design parameters. - Enhanced Stability:

These cylinders play a vital role in maintaining the stability of the shield machine during operation. By providing consistent support, they allow the machine to navigate through various geological conditions without compromising safety. This stability is essential for preventing accidents and ensuring the safety of both workers and the machinery itself, particularly in unpredictable environments. - Reduced Maintenance:

The durable design of shield machine hydraulic cylinders minimizes wear and tear, which leads to lower maintenance costs and less downtime. By requiring fewer repairs and replacements, these cylinders contribute to overall project efficiency. This reduction in maintenance not only saves money but also allows for more continuous operation, enhancing productivity on-site. - Versatility:

Shield machine hydraulic cylinders are suitable for a wide range of applications, including subways, sewer systems, and other forms of underground infrastructure. Their adaptability makes them an ideal choice for various tunneling needs, allowing contractors to use the same equipment across different projects. This versatility simplifies logistics and reduces the need for multiple specialized tools. - Safety Features:

Equipped with advanced safety mechanisms, these hydraulic cylinders help prevent accidental disengagement during operation. This feature ensures secure operation even under demanding excavation tasks, significantly enhancing the safety of the tunneling process. Such safety measures are crucial in maintaining a safe working environment and protecting the well-being of workers. - Hydraulic Power:

The use of hydraulic systems in these cylinders allows for greater force generation within a compact design. This capability makes it easier to manage heavy loads and execute complex movements with precision. The hydraulic power enables shield machines to perform efficiently, even in challenging conditions, thereby improving the overall effectiveness of tunneling operations.

By leveraging these advantages, shield machine hydraulic cylinders play a crucial role in the success of modern tunneling projects, ensuring efficiency, safety, and reliability throughout the excavation process. Their integration into tunneling machinery is vital for meeting the demands of contemporary infrastructure development.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX