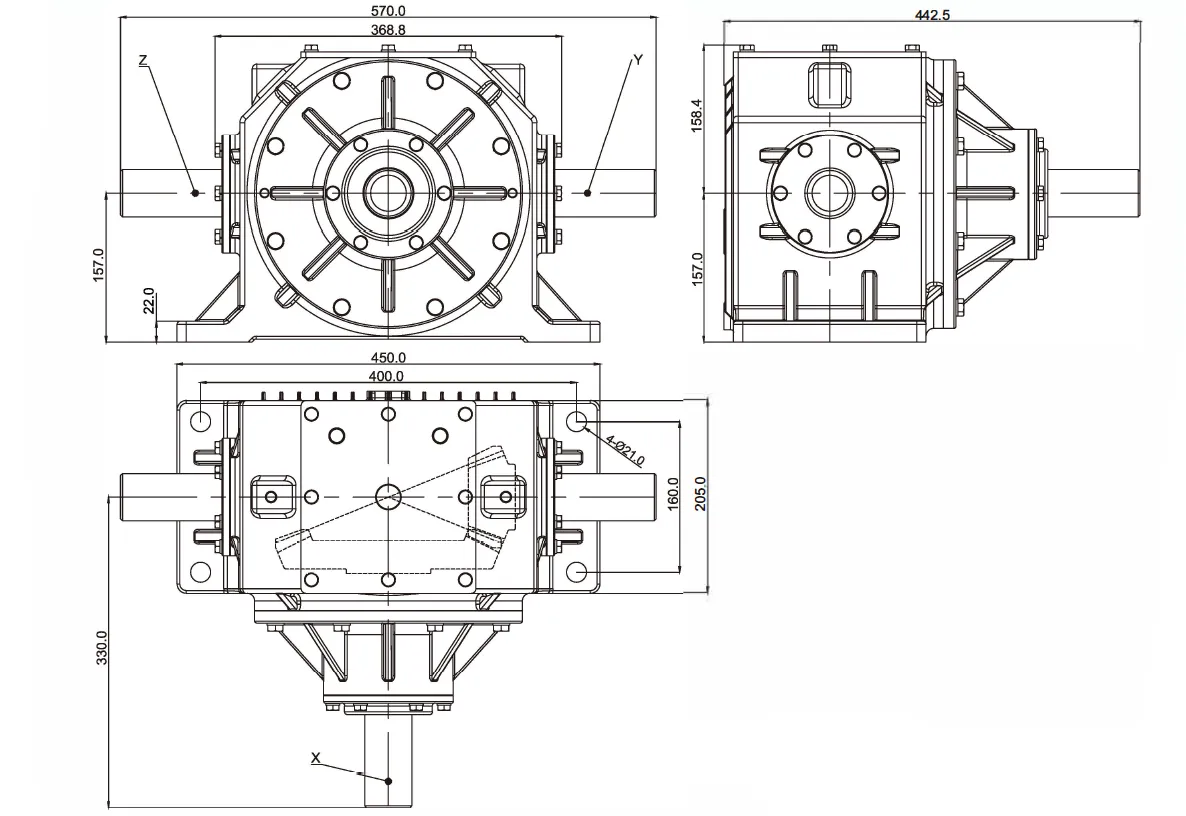

Square Baler Gearbox FMP-FK157 Dimensions

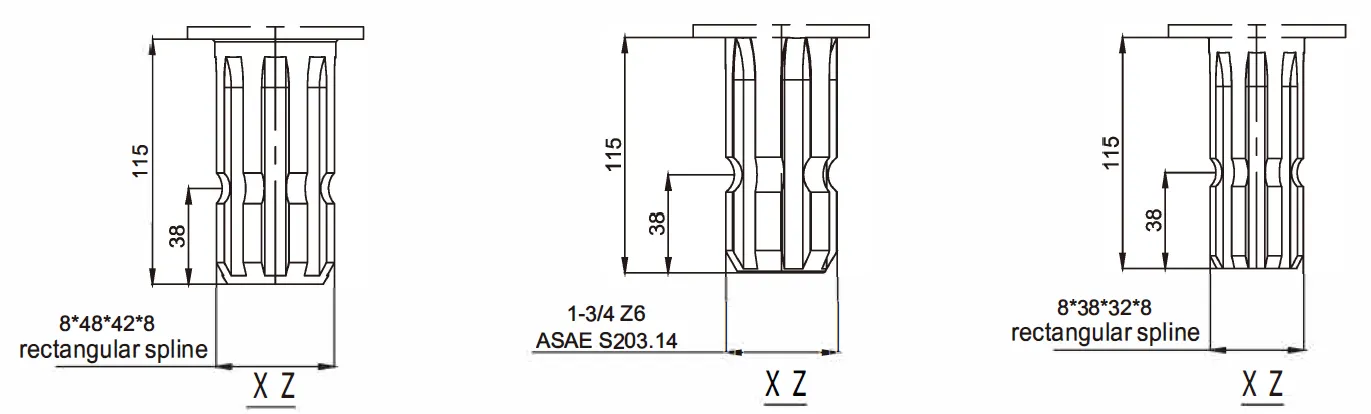

Square Baler Gearbox FMP-FK157 Shaft Dimensions

Square Baler Gearbox FMP-FK157 Technical Data

| i | Suitable | Rpm input | Rpm output | KW(Nom) | KW(Max) | Toothing | |

| r/min | r/min | hp | hp | ||||

| Speed increase | 1:2.46 | Straw chopper, etc | 540 | 1328.4 | 180 | 700 | Gleason Helical Zęby |

| Speed increase | 1:2.07 | 720 | 1190.4 | 180 | 700 | ||

| Remark: If you have any special require feel free let me know, we also accept custom. | |||||||

Components of Square Baler Gearbox FMP-FK157 for Straw Chopper

The Square Baler Gearbox FMP-FK157 is designed for applications such as straw chopping and baling, where durability, efficiency, and precision are critical. Below are the key components typically found in the FMP-FK157 Square Baler Gearbox, specifically designed to work with a straw chopper:

- Input Shaft

- Function: The input shaft connects the gearbox to the tractor or power take-off (PTO) system. It transmits rotational power from the tractor’s engine to the gearbox, enabling the straw chopper to operate.

- Material: Typically made of high-strength steel for durability and to withstand the stress from continuous use in agricultural applications.

- Output Shaft

- Function: The output shaft transfers the mechanical power from the gearbox to the connected straw chopper components, such as the cutting blades or flails.

- Material: Steel or alloy materials are used for resistance to wear and stress from the heavy-duty operation of chopping straw.

- Gear Set (Helical or Spur Gears)

- Function: The gear set is a critical component that adjusts the rotational speed and torque between the input and output shafts. It ensures the efficient transfer of power to the chopper mechanism.

- Type: Depending on the design, the gearbox may utilize helical or spur gears to optimize torque and reduce noise and vibration during operation.

- Material: Hardened steel for strength and durability.

- Bearings

- Function: Bearings support the shafts, reduce friction, and ensure smooth rotation. They are essential for maintaining the long-term efficiency and stability of the gearbox.

- Type: Ball or roller bearings, depending on the design and application.

- Seals

- Function: Seals prevent the leakage of oil or lubricant and protect the internal components of the gearbox from dirt, moisture, and other contaminants.

- Material: Rubber, nitrile, or other synthetic materials are used for long-lasting protection against environmental factors.

The FMP-FK157 Square Baler Gearbox is designed for heavy-duty agricultural applications, including straw chopping. The combination of durable materials, precise gear sets, efficient lubrication, and protective components ensures optimal performance and longevity in the challenging conditions of agricultural operations. Each of the components plays a vital role in enabling the gearbox to operate reliably and efficiently, facilitating smooth and efficient straw chopping and baling operations.

Step-by-Step Operation of the Square Baler Gearbox for Straw Chopper

The Square Baler Gearbox for Straw Chopper is a vital mechanical component that efficiently transfers power from the tractor’s power take-off (PTO) system to the straw chopper, enabling it to perform its tasks effectively. Here’s how the gearbox works in the context of a straw chopper:

- Power Transmission from PTO to Input Shaft

- The gearbox is connected to the tractor’s PTO shaft, which delivers rotational power from the tractor’s engine.

- When the tractor is activated, it turns the PTO, which then transfers this rotational force through the input shaft of the gearbox.

- Reduction or Speed Adjustment through Gear Set

- Inside the gearbox, a gear set (either helical or spur gears) adjusts the rotational speed and torque. The gears reduce the high-speed rotation from the PTO, converting it into a lower speed, higher torque output suitable for the straw chopper’s operations.

- This reduction gearing ensures that the straw chopper operates at the correct speed to effectively chop the straw and feed it into the baling chamber.

- Power Transmission to Output Shaft

- After the gears adjust the speed and torque, the output shaft transfers the modified power to the straw chopper.

- The output shaft connects directly to the cutting mechanism of the straw chopper, which includes rotating blades or flails that cut or shred the straw into smaller pieces.

- Movement of the Chopper Mechanism

- As the output shaft turns, it drives the blades or flails of the straw chopper, which are responsible for chopping the straw into small, uniform pieces.

- The chopped straw is then fed into the baling chamber or spread out depending on the intended use (e.g., for mulching or composting).

- Lubrication and Cooling

- The gearbox relies on a lubrication system (oil or grease) that circulates throughout the internal components (gears and bearings) to minimize friction, reduce wear, and keep the system running smoothly.

- In some designs, cooling fins or other cooling mechanisms may be used to dissipate heat generated by the continuous motion of the gearbox and the chopper mechanism.

The Square Baler Gearbox for Straw Chopper plays an essential role in transforming the tractor’s PTO power into the proper speed and torque needed for efficient chopping and baling of straw. It does so by utilizing a combination of input and output shafts, gear sets, and protective components, while ensuring lubrication and protection against excessive loads. This mechanical process ensures that the straw chopper operates reliably, reducing downtime and enhancing overall productivity in agricultural operations.

O FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Autor: CX