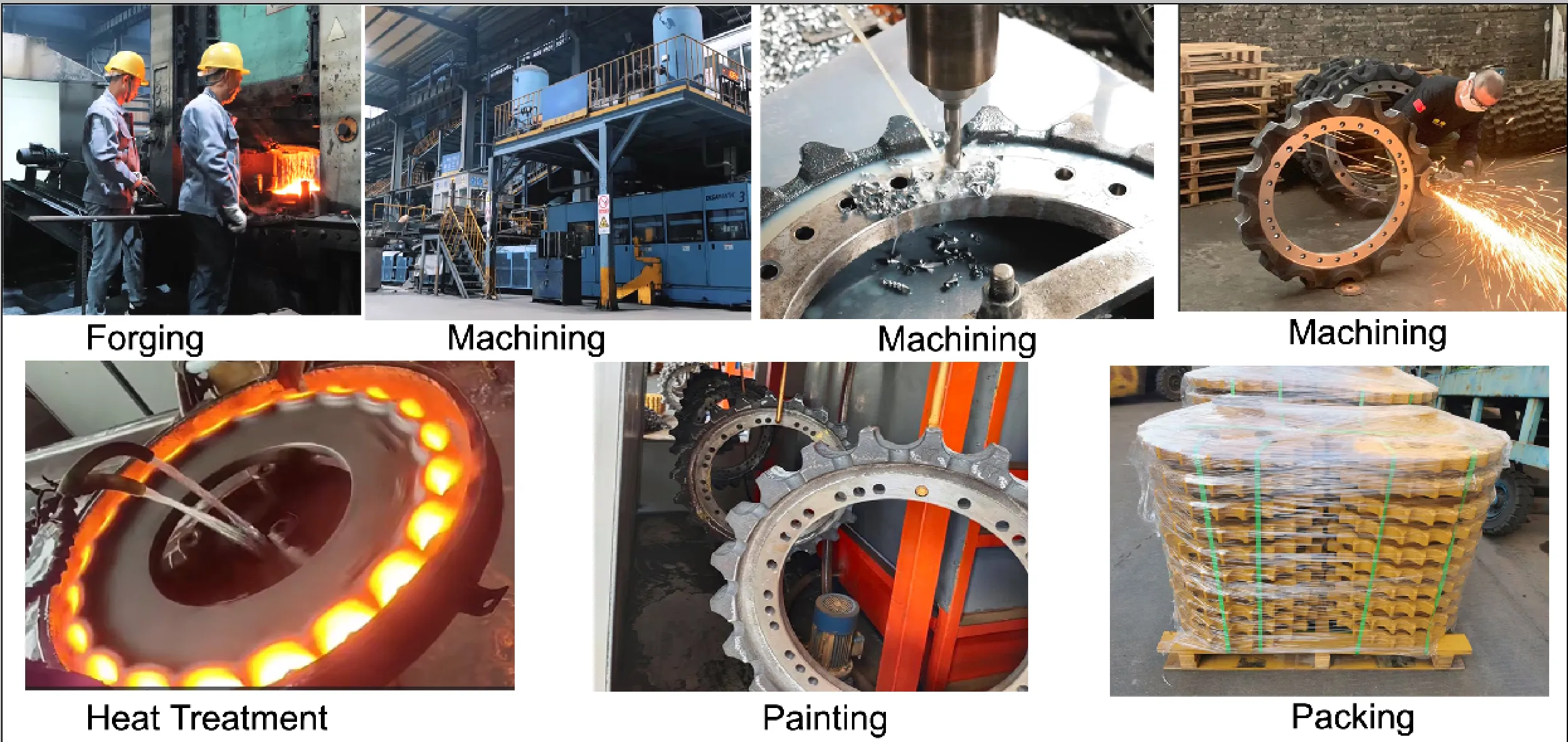

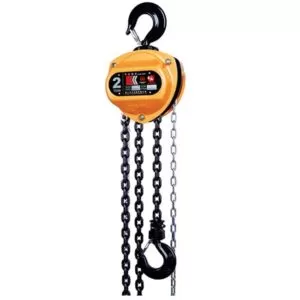

Chain Hoist Sprocket Product Overview

The chain hoist sprocket is designed for ease of operation, portability, and safety, making it a popular choice among users. With its innovative design and smooth functionality, this sprocket excels in heavy lifting applications. But what sets it apart?

The chain hoist sprocket is built with components such as hooks, chains, and other parts that have high load-bearing capacity, excellent toughness, and strength. These features ensure that the sprocket remains durable and resistant to breakage during use, significantly improving operational safety. The sprocket’s robust construction allows it to lift heavy loads consistently over long periods, enhancing work efficiency and reducing the need for manual labor.

Widely used across industries such as power, transportation, bridge construction, and coal, the chain hoist sprocket offers unique advantages that contribute to more efficient and safer operations in various fields, making it an invaluable tool for improving productivity.

Upgraded Fixed Pulley Design

The chain hoist sprocket is an advanced version of the traditional fixed pulley, combining the best features of the fixed pulley with added functionality. It integrates a reducer, reverse check brake, and the chain hoist sprocket, all within a symmetric secondary spur gear system. This setup is simple, durable, and highly efficient.

The operation is straightforward: the manual chain and hand chain wheel are pulled to engage the friction plate ratchet and brake seat, causing them to turn together. As the tooth-long shaft rotates the plate gear, the short tooth shaft and spline hole gear follow suit. This action drives the lifting chain wheel, which in turn moves the lifting chain to raise the heavy load steadily. Additionally, the one-way brake mechanism, featuring a ratchet friction plate, ensures automatic braking under load. The pawl engages with the ratchet under spring tension, allowing the brake to work safely and securely.

The chain hoist sprocket is engineered to provide reliable, efficient, and safe lifting, making it an ideal choice for demanding industrial tasks.

Maintenance of Hand Chain Hoist Sprocket

The hand chain hoist sprocket is primarily used for lifting heavy objects and installing equipment. To ensure a safe and smooth operation, the following steps should be followed before commencing any lifting tasks:

- Check Load Capacity: Ensure that the weight of the object being lifted is within the rated load capacity of the hand chain hoist to prevent overloading.

- Inspect the Work Environment: Verify that the work area meets the necessary safety requirements. Establish a designated safety zone around the lifting operation to minimize the risk of accidents.

- Examine the Hoist Components: Inspect the hand chain hoist, paying close attention to any signs of rust, wear, or cracks in its parts. If any issues are found, halt the operation immediately and replace or repair the damaged components.

- Secure the Load: Ensure that the load is properly secured before lifting to prevent it from falling during the operation.

By following these maintenance and safety guidelines, you can ensure the longevity of your hand chain hoist sprocket while also maintaining a safe working environment.

| Hand chain hoist | Electric chain hoist | Lever hoist | Gear trolley |

|

|

|

|

|

|

|

|

Chain hoist sprocket made of other materials

| Plastic chain hoist sprocket | Stainless steel chain hoist sprocket |

|

|

O FMP

At FMP, we pride ourselves on being a leading manufacturer of high-quality sprockets, produced in our advanced facility in Italy. We offer a diverse range of sprockets designed to meet the unique needs of various industries. Whether you’re looking for finished bore sprockets, idler sprockets, taper lock sprockets, or conveyor sprockets, we craft each product with precision and durability to ensure optimal performance. Our selection includes stainless steel, plastic, and steel sprockets, as well as specialized models like double pitch and double row sprockets, allowing us to provide the ideal solution for any application.

What sets FMP apart is our dedication to customization. We recognize that every project has its own specific requirements, which is why we offer bespoke sprocket solutions tailored to your exact needs. Whether you require a custom design or have specialized technical demands, our expert team is ready to deliver precise, reliable, and high-performance solutions.

We are committed to excellence in both engineering and manufacturing, ensuring that each sprocket we produce meets the highest quality standards and is built to last. If you have any inquiries or need a customized sprocket solution, don’t hesitate to contact us. Our team is here to provide you with expert guidance and timely responses to ensure your complete satisfaction. Simply reach out via email, and we will get back to you as soon as possible.