The 10016 Hot Selling Trailer Hydraulic Cylinder is expertly designed to enhance the functionality of agricultural trailers, providing reliable performance and robust durability. This hydraulic cylinder is an essential component for farmers looking to maximize efficiency and ease of operation in their agricultural activities.

Główne cechy:

- Efficient Hydraulic Performance:

The 10016 hydraulic cylinder is engineered for optimal hydraulic fluid performance, ensuring smooth and powerful operation for lifting and lowering trailer beds. This efficiency is crucial for quick loading and unloading, improving overall productivity. - Robust Construction:

Made from high-quality materials, this hydraulic cylinder is built to withstand the demanding conditions of agricultural environments. Its durable construction ensures long-lasting performance, even under heavy loads and frequent use. - Versatile Applications:

Designed specifically for agricultural trailers, this hydraulic cylinder is versatile enough to be used in various applications, including hay transport, livestock hauling, and general farming tasks. Its adaptability makes it a valuable addition to any farming operation. - User-Friendly Design:

The 10016 cylinder features an intuitive design that simplifies installation and operation. It is compatible with a range of trailer models, making it easy for farmers to upgrade their equipment without extensive modifications. - Hot Selling Item:

With its proven performance and reliability, the 10016 hydraulic cylinder has become a hot selling item among agricultural professionals. Its popularity is a testament to its quality and effectiveness in enhancing agricultural operations.

Technical Specifications:

| Specyfikacja | Description |

|---|---|

| Rozmiar otworu | Customizable |

| Stroke Length | Various options available |

| Maximum Pressure | Up to 3000 PSI |

| Tworzywo | High-quality steel or aluminum |

| Connection Type | Flanged or threaded |

Working Principle:

The 10016 Trailer Hydraulic Cylinder operates based on the principle of hydraulic fluid pressure. When hydraulic fluid is pumped into the cylinder, it exerts force on the piston, allowing for controlled lifting and lowering of the trailer bed. This effective power transfer ensures that farmers can handle heavy loads with ease and precision.

The 10016 Hot Selling Trailer Hydraulic Cylinder is a reliable and efficient solution for enhancing agricultural trailer operations. Its robust construction, user-friendly design, and versatility make it an indispensable tool for farmers looking to improve their productivity and efficiency in the field.

Często zadawane pytania

– Are the trailer hydraulic cylinders customizable?

Yes, we offer customization based on your specifications and requirements.

– What is the carrying capacity of the trailer hydraulic cylinder?

The carrying capacity depends on the model. Please refer to the product details for more information.

– How does a trailer hydraulic cylinder work?

Hydraulic cylinders work on the principle of fluid mechanics. When pressure is applied to the fluid in the cylinder, it creates a force that can move heavy objects.

– What is the energy efficiency of these cylinders?

Our trailer hydraulic cylinders are designed to use less energy, making them cost-effective and environmentally friendly.

– Are these cylinders safe?

Yes, our cylinders are built with top-quality materials and advanced technology, ensuring safe and reliable performance.

Zalety cylindra spawanego typu trójnikowego

-

- Zwiększona siła: Spawane cylindry typu tee są znane ze swojej wysokiej wytrzymałości, dzięki czemu nadają się do zastosowań wymagających podnoszenia ciężarów. Proces spawania stosowany podczas produkcji tych cylindrów zapewnia, że cylinder jest wolny od słabych punktów i może wytrzymać wysokie ciśnienie i naprężenia.

Gdy na cylinder wywierany jest nacisk, rozprowadza się on równomiernie po całej powierzchni, co czyni go odpornym na odkształcenia. Ta cecha zapewnia, że cylinder może zachować swój kształt i integralność strukturalną nawet w ekstremalnych warunkach.

-

- Zapobieganie wyciekom: Spawane cylindry typu tee są zaprojektowane tak, aby zapobiegać wyciekom. Proces spawania stosowany podczas procesu produkcji zapewnia, że cylinder jest całkowicie szczelny i wolny od wszelkich możliwych wycieków. Ta cecha sprawia, że nadają się do stosowania w zastosowaniach, w których wyciek mógłby spowodować poważne uszkodzenia lub obrażenia.

Połączenia spawane są gładkie, bez szczelin czy rowków, w których mogłyby gromadzić się zanieczyszczenia lub brud, co zmniejsza ryzyko korozji i uszkodzenia cylindra.

-

- Możliwość dostosowania: Spawane cylindry typu tee można dostosować do konkretnych zastosowań. Cylindry są dostępne w różnych rozmiarach i kształtach i mogą być wytwarzane tak, aby spełniały konkretne wymagania danego zastosowania.

Proces dostosowywania pozwala na optymalizację wydajności cylindra, zapewniając, że jest on odpowiedni do zamierzonego zastosowania. Ta cecha sprawia, że spawane cylindry typu tee są idealne do stosowania w różnych zastosowaniach przemysłowych, w tym w budownictwie, górnictwie i transporcie materiałów.

-

- Opłacalność: Spawane cylindry typu tee są opłacalne w porównaniu do innych typów cylindrów. Proces produkcji tych cylindrów jest prosty, co czyni je tańszymi od innych typów cylindrów.

Ponadto wysoka wytrzymałość i trwałość spawanych cylindrów typu tee zmniejszają potrzebę częstych napraw i wymian, co pozwala zaoszczędzić na kosztach konserwacji. Ta cecha sprawia, że są one popularnym wyborem dla wielu branż, szczególnie tych o ograniczonym budżecie.

-

- Zwiększona wydajność: Spawane cylindry typu tee są wysoce wydajne i skuteczne. Konstrukcja cylindra zapewnia, że siła przyłożona jest przenoszona bezpośrednio na obciążenie, co zmniejsza straty energii i zwiększa wydajność.

Spawane połączenia są mocne i sztywne, minimalizując ugięcie i zapewniając, że cylinder zachowuje swój kształt i integralność strukturalną nawet w ekstremalnych warunkach. Ta cecha sprawia, że spawane cylindry typu tee są idealne do zastosowań wymagających wysokiej wydajności i niezawodności.

Zastosowanie cylindra spawanego typu trójnikowego

Introduction

Welded tee type cylinder is a type of hydraulic cylinder that is commonly used in industrial applications. It is designed to provide high force output in a compact and cost-effective package. This type of cylinder consists of a welded tee and a piston rod that is attached to the tee. The tee is connected to the barrel of the cylinder and contains a piston that moves back and forth inside the barrel to generate force.

Zalety cylindra spawanego typu trójnikowego

There are several advantages to using a welded tee type cylinder in industrial applications:

- Compact design: Welded tee type cylinders are designed to be compact, which makes them ideal for use in applications where space is limited.

- High efficiency: Welded tee type cylinders are highly efficient, which means that they can generate a large amount of force with minimal energy input.

- Durable: Welded tee type cylinders are designed to be highly durable, which means that they can withstand harsh operating conditions and last for a long time.

- Cost-effective: Welded tee type cylinders are cost-effective, which means that they provide good value for money.

Applications of Welded Tee Type Cylinder

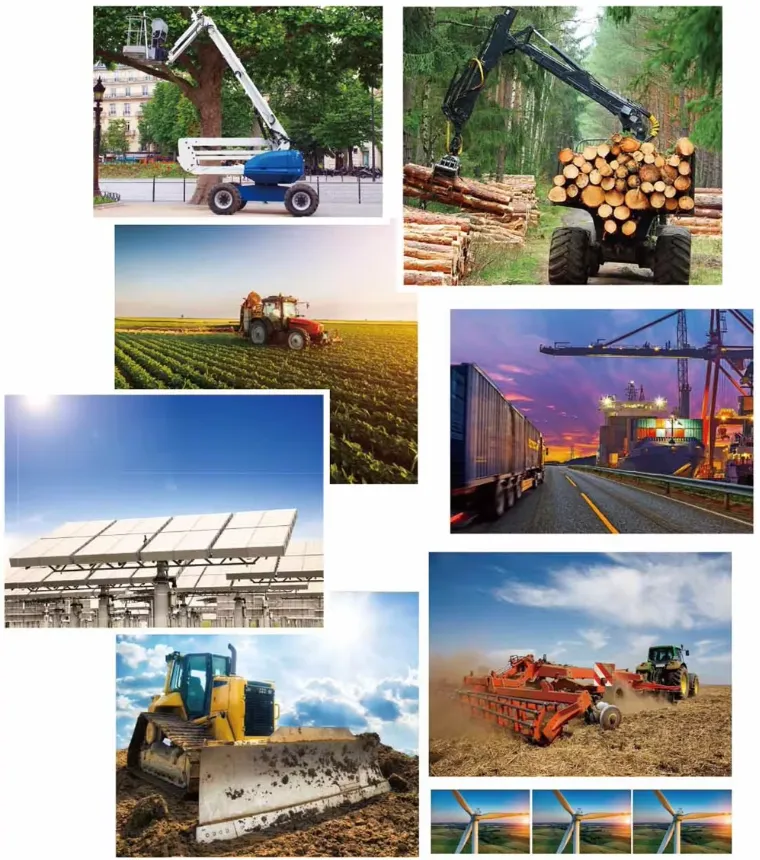

There are many applications for welded tee type cylinders in various industries, including:

- Manufacturing: Welded tee type cylinders are used in manufacturing to operate machinery, move heavy loads, and shape metal parts.

- Agriculture: Welded tee type cylinders are used in agriculture to operate hydraulic systems on tractors, harvesters, and other farm equipment.

- Construction: Welded tee type cylinders are used in construction to operate machinery such as cranes, excavators, and backhoes.

- Mining: Welded tee type cylinders are used in mining to operate hydraulic systems on heavy equipment such as bulldozers, loaders, and rock drills.

- Transportation: Welded tee type cylinders are used in transportation to operate hydraulic systems on trucks, buses, and other vehicles.

In conclusion, welded tee type cylinders are an important component in many industrial applications. They are designed to be compact, efficient, durable, and cost-effective, making them an ideal choice for a wide range of applications. Whether you are operating machinery in a manufacturing plant, farming equipment on a farm, or heavy equipment in a mine, welded tee type cylinders can help you get the job done efficiently and effectively.

O FMP

FMP, with over 30 years of establishment in Italy, is a leading manufacturer and seller of various types of Hydraulic Cylinders. We take pride in offering customized solutions to meet our customers’ unique requirements. With more than 100 state-of-the-art equipment, including automatic gas shielded welding machines, deep hole boring machines, CNC lathes, cylindrical grinders, automatic cleaning machines, automatic installation machines, automatic hydraulic cylinder performance test benches, and automatic painting lines, we ensure the highest quality standards in our products.

1) Design Service: Our experienced design team is adept at product design and development. Whether you need new products or improvements on existing ones, we are here to support you.

2) Product Service: From raw materials to cutting, rough processing, testing, cleaning, assembly, packaging, and transportation, we meticulously manage every step to ensure superior quality.

3) Sample Process: We can develop samples according to your specific requirements and constantly modify them to meet your needs. Your satisfaction is our priority.

4) R&D: With a focus on market trends and customer demands, we continuously study new needs and develop innovative hydraulic cylinder models.

5) Strict Processing and Inspection: Each hydraulic cylinder undergoes rigorous processing and inspection to guarantee exceptional quality and reliability for our valued customers.

Autor:CX