I giunti flessibili FMP sono realizzati per ridurre le vibrazioni e tagliare i costi di riparazione dei sistemi di trasmissione. Il loro design speciale aiuta a proteggere la trasmissione dai danni e produce meno rumore durante il funzionamento, il che fa sì che il sistema funzioni meglio e duri più a lungo. Inoltre, questi giunti sono facili da installare e regolare, così puoi risparmiare tempo e fatica.

FMP utilizza un elastomero poliestere resistente per realizzare i propri giunti. Questo materiale è resistente e non si deforma, anche quando entra in contatto con fluidi lubrificanti. Ciò mantiene il giunto resistente e funzionante, anche in condizioni difficili.

Il giunto è costruito per trasferire la coppia (un tipo di forza di rotazione) in modo costante a circa un quarto di pollice al minuto. Questa forza regolare e costante aiuta il giunto a durare più a lungo, così può funzionare bene per anni con pochissima manutenzione.

Grazie a queste caratteristiche, i giunti flessibili FMP rappresentano la scelta ideale se si desidera che il sistema di trasmissione funzioni meglio e duri più a lungo.

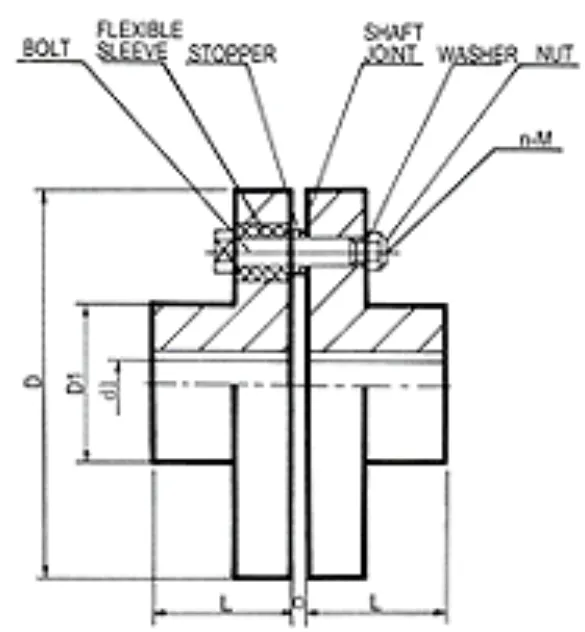

Specifiche dei giunti flessibili flangiati

| MISURARE | nanometro | giri/min | D | La 1a | e1 il1 | L | C | nuovoM | KG |

| 90 | 4 | 4000 | 90 | 35.5 | 11 | 28 | 3 | 4-M8*50 | 1.7 |

| 100 | 10 | 4000 | 100 | 40 | 11 | 35.5 | 3 | 4-M10*56 | 2.3 |

| 112 | 16 | 4000 | 112 | 45 | 13 | 40 | 3 | 4-M10*56 | 2.8 |

| 125 | 25 | 4000 | 125 | 50 | 13 | 45 | 3 | 4-M12*64 | 4.0 |

| 140 | 50 | 4000 | 140 | 63 | 13 | 50 | 3 | 6-M12*64 | 5.4 |

| 160 | 110 | 4000 | 160 | 80 | 15 | 56 | 3 | 8-M12*64 | 8.0 |

| 180 | 157 | 3500 | 180 | 90 | 15 | 63 | 3 | 8-M12*64 | 10.5 |

| 200 | 245 | 3200 | 200 | 100 | 21 | 71 | 4 | 8-M20*85 | 16.2 |

| 224 | 392 | 2850 | 224 | 112 | 21 | 80 | 4 | 8-M20*85 | 21.3 |

| 250 | 618 | 2550 | 250 | 125 | 25 | 90 | 4 | 8-M24*100 | 31.6 |

| 280 | 980 | 2300 | 280 | 140 | 34 | 100 | 4 | 8-M24*116 | 44.0 |

| 315 | 1568 | 2050 | 315 | 160 | 41 | 112 | 4 | 10-M24*116 | 57.7 |

| 355 | 2450 | 1800 | 355 | 180 | 60 | 125 | 5 | 8-M30*150 | 89.5 |

| 400 | 3920 | 1600 | 400 | 200 | 60 | 125 | 5 | 10-M30*150 | 89.5 |

| 450 | 6174 | 1400 | 450 | 224 | 65 | 140 | 5 | 12-M30*150 | 145 |

| 560 | 9800 | 1150 | 560 | 250 | 85 | 160 | 5 | 14-M30*150 | 229 |

| 630 | 15680 | 1000 | 630 | 280 | 95 | 180 | 5 | 18-M30*150 | 296 |

Tipi di giunto flessibile

I giunti flessibili sono dispositivi meccanici utilizzati per collegare due alberi, consentendo la trasmissione della coppia compensando al contempo i disallineamenti e riducendo le sollecitazioni sui componenti collegati. Un tipo comune è il giunto a ganasce, costituito da due mozzi con ganasce interbloccate e un inserto elastico a ragno. Il ragno assorbe gli urti, smorza le vibrazioni e compensa piccoli disallineamenti angolari, paralleli e assiali, rendendolo ideale per applicazioni generiche come pompe e motori.

Un altro tipo di giunto è il giunto a soffietto, caratterizzato da un sottile soffietto metallico flessibile che collega gli alberi. Questa configurazione offre un'elevata rigidità torsionale per una trasmissione precisa della coppia, consentendo al contempo la flessibilità necessaria per gestire disallineamenti angolari e assiali. I giunti a soffietto sono spesso utilizzati in sistemi ad alta precisione, come servomotori ed encoder, dove il mantenimento della precisione in condizioni dinamiche è fondamentale.

Un terzo tipo è il giunto a disco, che utilizza una serie di dischi metallici sottili e flessibili impilati insieme a formare un pacco. Il pacco dischi si flette per compensare il disallineamento e assorbe le vibrazioni, pur trasmettendo la coppia in modo efficiente. I giunti a disco sono estremamente resistenti e adatti ad applicazioni impegnative, come turbine e compressori, dove affidabilità e manutenzione minima sono essenziali.

Giunti flessibili flangiati: ingegneria di precisione dagli esperti italiani di giunti FMP

FMP è un'azienda italiana leader nella produzione di giunti, specializzata in un'ampia gamma di giunti progettati per trasferire la coppia tra gli alberi, compensando al contempo disallineamenti e movimenti. Che operiate nel vivace settore manifatturiero milanese o in un laboratorio artigianale fiorentino, i nostri giunti flessibili flangiati, realizzati con materiali resistenti come acciaio inossidabile, gomma e ottone, garantiscono una trasmissione di potenza impeccabile ed efficienza operativa in applicazioni che spaziano dai gruppi pompa alla propulsione marina.

FMP è orgogliosa di offrire un'ampia gamma di tipologie di giunti, tra cui giunti meccanicamente flessibili, con elementi metallici ed elastomerici, tutti progettati su misura per soddisfare specifiche esigenze industriali. Oltre alla nostra vasta gamma di prodotti, offriamo anche soluzioni personalizzate per clienti in Italia e all'estero. Se vi trovate a Bologna e avete bisogno di un giunto flessibile flangiato unico per le vostre macchine agricole, o se cercate un progetto personalizzato per un'applicazione ad alta velocità a Milano, gli ingegneri esperti di FMP sono pronti a collaborare con voi. Il nostro processo di personalizzazione garantisce che ogni giunto sia costruito secondo le vostre specifiche, offrendo prestazioni e durata su cui potete contare.

Non trovi il modello esatto che ti serve nel nostro catalogo prodotti? Non preoccuparti: il nostro catalogo è in continuo aggiornamento e potremmo non aver ancora caricato tutte le opzioni. Per aziende a Firenze, Bologna o altrove, inviaci le tue esigenze via email. Il nostro team dedicato di ingegneri italiani ti risponderà entro 24 ore con consigli e soluzioni personalizzate.