Internal Planetary Gears: Precision and Power by FMP

Internal planetary gears, a vital component of planetary gear mechanisms, are renowned for their ability to deliver high torque and precise speed reduction in compact designs. These systems feature a central sun gear, orbiting planet gears, and an internal ring gear that meshes internally with the planet gears. This unique configuration makes internal planetary gears essential for industries across Italy, from the automotive workshops of Milan to the machinery hubs of Bologna. At FMP, we specialize in crafting these advanced gear systems, offering tailored solutions to meet the diverse needs of our clients.

What Are Internal Planetary Gears?

An internal planetary gear system consists of:

- Sun Gear: The central gear that drives the mechanism.

- Planet Gears: Gears that orbit the sun gear, connected by a carrier.

- Internal Gear (Ring Gear): A gear with teeth on its inner surface, meshing with the planet gears.

Unlike external gear systems, the internal gear design allows for higher reduction ratios in a smaller footprint, making it ideal for applications that require power and space efficiency. By fixing different components (such as the internal gear or the carrier), the system can achieve different reduction ratios, providing flexibility to engineers everywhere.

Spécification

| Numéro de modèle | M3, M4, M5, M8, M12 et etc. |

| Matériel | Laiton, acier C45, acier inoxydable, cuivre, POM, aluminium, alliage, etc. |

| Traitement de surface | Zingué, Nickelé, Passivation, Oxydation, Anodisation, |

| Géomet, Dacromet, oxyde noir, phosphatation, revêtement en poudre et électrophorèse | |

| Standard | ISO, DIN, ANSI, JIS, BS et non standard. |

| Précision | DIN6, DIN7, DIN8, DIN9. |

| Traitement des dents | Trempé, fraisé ou rectifié |

| Tolérance | 0,001 mm-0,01 mm-0,1 mm |

| Finition | grenaillage/sablage, traitement thermique, recuit, revenu, polissage, anodisation, zingage |

| Emballage des articles | Sac en plastique + cartons ou emballage en bois |

| Délai de production | 20 jours ouvrables pour l'échantillon, 25 jours pour le gros |

| Application | 1. Machine de contrôle automatique |

| 2. Industrie des semi-conducteurs | |

| 3. Machines pour l'industrie générale | |

| 4. Équipement médical | |

| 5. Équipement d'énergie solaire | |

| 6. Machine-outil | |

| 7. Système de stationnement | |

| 8. Équipements de transport ferroviaire à grande vitesse et aérien, etc. |

Why Choose Internal Planetary Gears?

The benefits of internal planetary gears include:

- High Reduction Ratios: Achieved through the internal gear’s interaction with planet gears.

- Taille compacte: Perfect for space-constrained applications.

- Robust Torque Output: Ideal for heavy-duty tasks.

- Versatilité: Adjustable configurations suit a range of needs.

For businesses in Milan’s automotive sector or Florence’s industrial zones, these advantages translate into enhanced efficiency and durability.

FMP: Your Expert in Internal Planetary Gears in Italy

At FMP, we are proud to be a leading manufacturer of internal planetary gears, serving clients from Venice to Bologna. Our offerings include:

- Diverse Range: We produce various types of internal planetary gears, from standard designs to complex systems.

- Personnalisation: Need a bespoke solution? Our engineers can design and manufacture custom internal planetary gears tailored to your specifications.

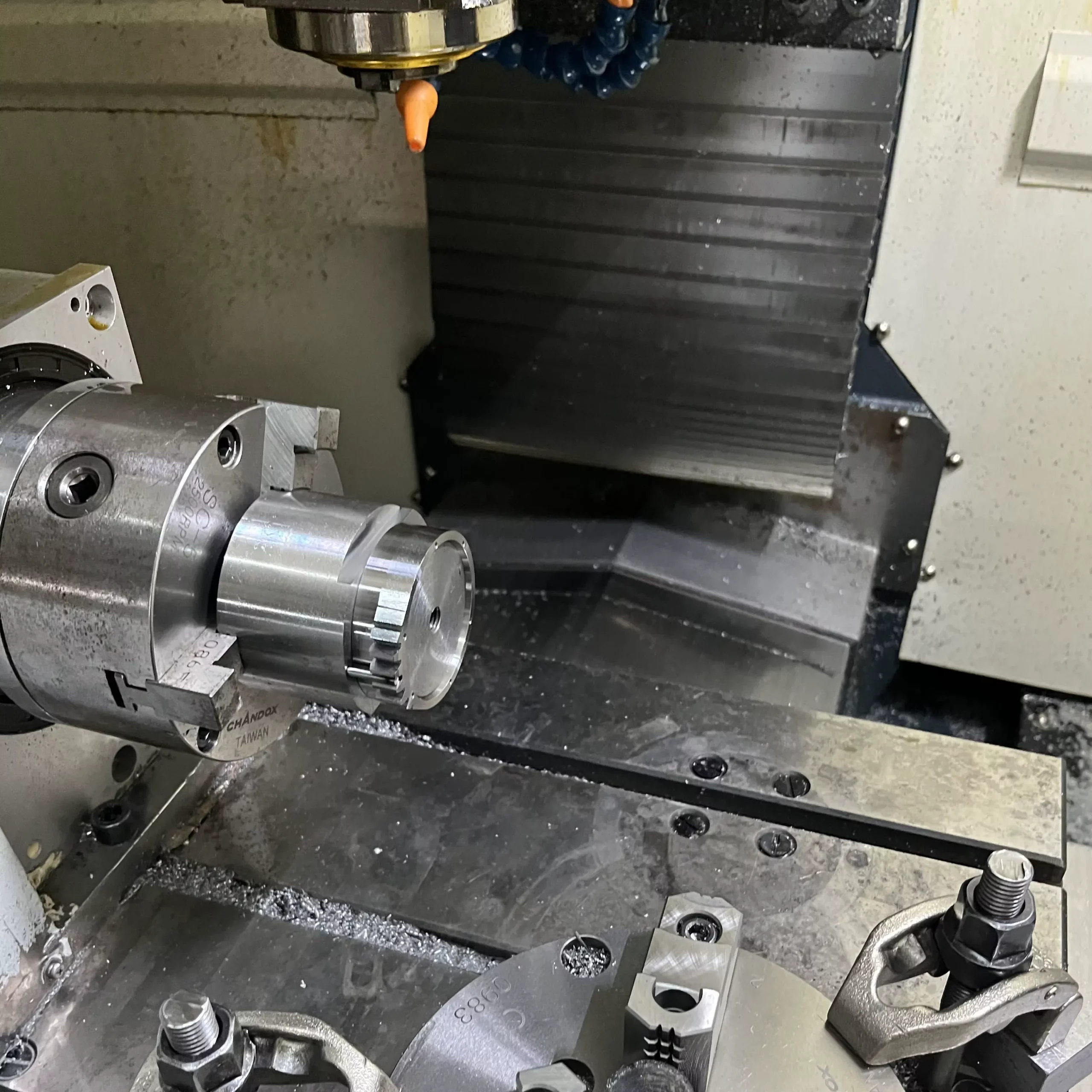

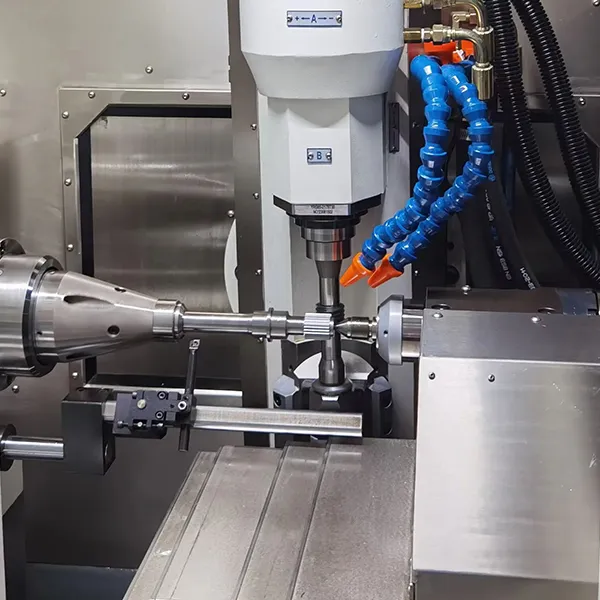

- Precision Craftsmanship: Leveraging advanced technology, we ensure every gear meets stringent quality standards.

|

|

|