Features of FMP-DWJC Series

- High-Precision Transmission: Utilizes a helical gear and worm gear structure, with precision-ground gears for smooth operation, low noise, high output torque, and excellent transmission efficiency.

- Durable and Lightweight Housing: Made from precision aluminum die-casting, offering an attractive design, light weight, and superior heat dissipation.

- Flexible Installation: Supports both bottom and side mounting, simplifying installation and reducing labor intensity for workers.

- Accurate Limit Control: Equipped with a spring-leaf limit device for easy and precise limit adjustments, allowing motor stop control within a range of 1 to 75 rotations. Includes dual safety switches for secure operation.

- Applications polyvalentes: Ideal for agricultural greenhouse window and curtain systems, livestock shed ventilation, and other scenarios requiring high gear ratios and controlled motion range.

Secification

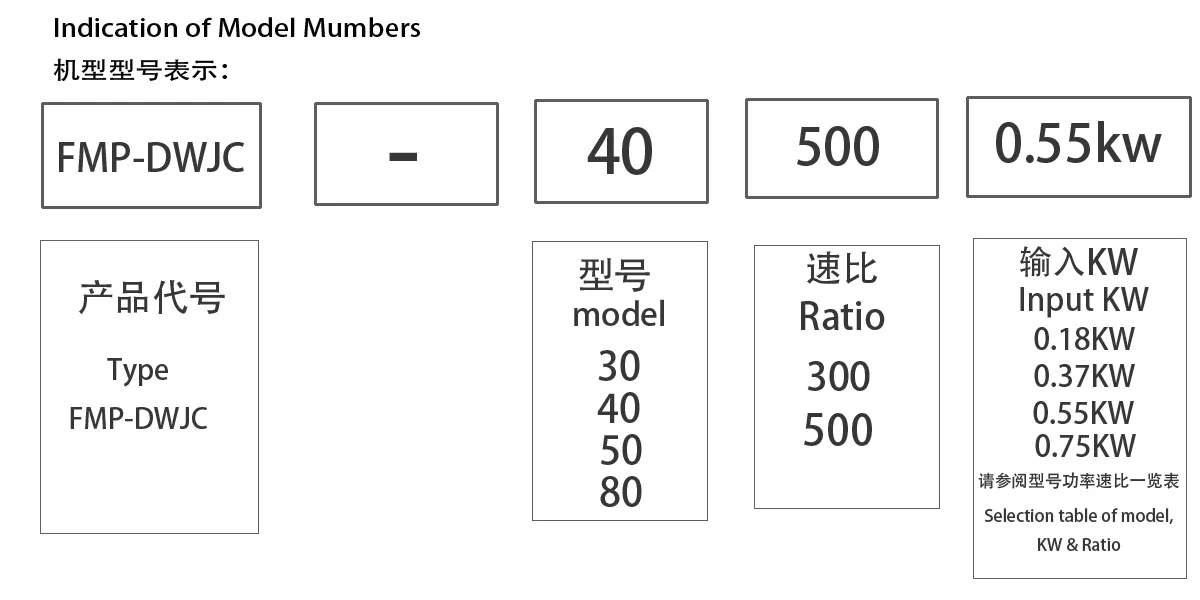

Indication of Model Mumbers

Selection Table of Model,KW & Ratio

| 型号 Model |

速比 RATIO | 输出转速 OUTPUT SPEED r/min | 输出扭矩 OUTPUT TORQUE Nm | 输入功率 INPUT kW | 电机保护等级 MOTOR SFEFY GADE | 电压 VOLTAGE V | 频率 FREQUENCY Hz | 限位控制范围 LIMIT CONTROL range |

| FMP-DWJC-30 | 1 | 300 | 0.18 | lp55 | 380 | 50 | 1~75转 (输入单轴转速) 1~75r (OUTPUT SPEED) |

|

| FMP-DWJC-40 | 500 | 2.6 | 400 | 0.37 | ||||

| 300 | 5.2 | 300 | 0.37 | |||||

| FMP-DWJC-50 | 500 | 2.6 | 600 | 0.55 | ||||

| 300 | 5.2 | 400 | 0.55 | |||||

| FMP-DWJC-80 | 500 | 2.6 | 800 | 0.75 | ||||

| 300 | 5.2 | 600 | 0.75 |

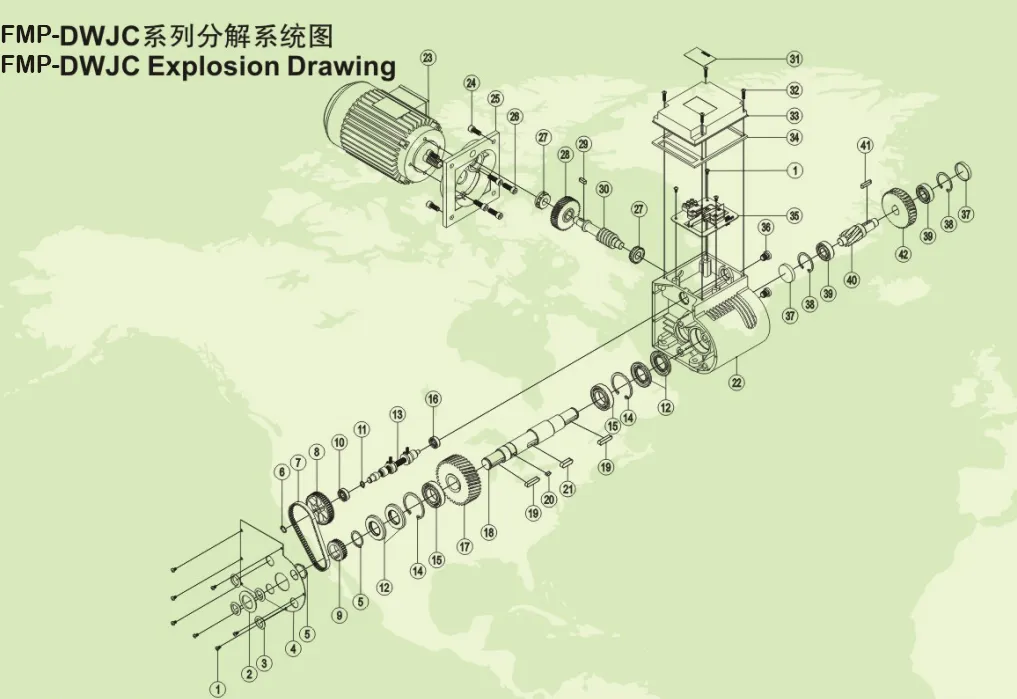

Explosion Drawing

| 编号 NO. | 零件名称 Name of Parts | 编号 NO. | 零件名称 Name of Parts |

| 1 | 十字槽盘头螺钉 CROSS RECESS PAN HEAD SCREW | 22 | 钢柱 Box |

| 2 | 密封圈 SEALING RING | 23 | 电机 MOTOR |

| 3 | 侧盖 SIDE COVER | 24 | 六角窝头螺钉 HEXAGON SOCKET HEAD CAP SCREWS |

| 4 | 轴用弹性挡圈 CIRCLIPS FOR SHAFT | 25 | 机盖 COVER |

| 5 | 同步带 SYNCHRONOUS BELT | 26 | 六角窝头螺钉 HEXAGON SOCKET HEAD CAP SCREWS |

| 6 | 同步轮 SYNCHRONOUS WHEEL | 27 | 滚珠轴承 BALL BEARING |

| 7 | 同步轮 SYNCHRONOUS WHEEL | 28 | 齿轮 GEAR |

| 8 | 深沟球轴承 BALL BEARING | 29 | 键槽用键 KEY |

| 9 | 轴用弹性挡圈 CIRCLIPS FOR SHAFT | 30 | 键槽用键 WORM SHAFT |

| 10 | 油封 Oil SEAL | 31 | 铭牌 NAMEPLATE |

| 11 | 限位模块 LIMIT MODULE | 32 | 十字槽盘头螺钉 CROSS RECESS PAN HEAD SCREW |

| 12 | 孔用弹性挡圈 CIRCLIPS FOR HOLE | 33 | 控制器盖 PACKING COVER |

| 13 | 深沟球轴承 BALL BEARING | 34 | 控制器模块 CONTROLLER MODULE |

| 14 | 齿轮 GEAR | 35 | 六角窝头螺钉 HEXAGON SOCKET HEAD CAP SCREWS |

| 15 | 输出轴 OUTPUT SHAFT | 36 | 孔用弹性挡圈 CIRCLIPS FOR HOLE |

| 16 | 键槽用键 KEY | 37 | 滚珠轴承 BALL BEARING |

| 17 | 键槽用键 KEY | 38 | 输出齿轮 GEAR SHAFT |

| 18 | 键槽用键 KEY | 39 | 键槽用键 KEY |

| 19 | 键槽用键 KEY | 40 | 蜗轮 WORM GEAR |

| 20 | 键槽用键 KEY | 41 | 键槽用键 KEY |

| 21 | 键槽用键 KEY | 42 | 蜗轮 WORM WHEEL |

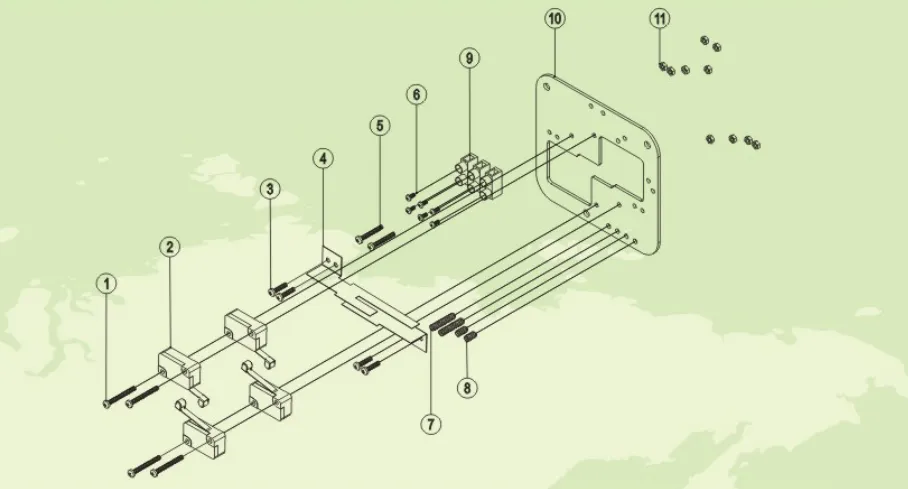

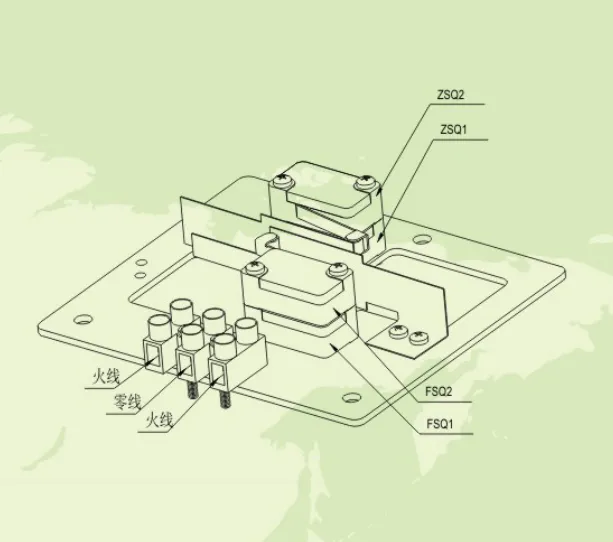

Controller Module Explosion Drawing

| 编号 NO. | 零件名称 Name of Parts |

| 1 | 十字槽盘头螺钉 CROSS RECESS PAN HEAD SCREW |

| 2 | 微动开关 MICRO SWITCH |

| 3 | 十字槽盘头螺钉 CROSS RECESS PAN HEAD SCREW |

| 4 | 弹簧片 LEAF SPRING |

| 5 | 十字槽盘头螺钉 CROSS RECESS PAN HEAD SCREW |

| 6 | 内六角平头紧定螺钉 CROSS HEXAGON SOCKET SET SCREW WITH FLAT POINT |

| 7 | 内六角平头紧定螺钉 HEXAGON SOCKET SET SCREW WITH FLAT POINT |

| 8 | 接线端子 AMPHENOL CONNECTOR |

| 9 | 底板 BASE PLATE |

| 10 | 六角螺帽 HEX NU |

Limit Module Explosion Drawing

| 编号 NO. | 零件名称 NAME of PARTS |

| 1 | 內六角平端緊定螺釘 HEXAGON SOCKET SET SCREW WITH FLAT POINT |

| 2 | 限位螺母 STOP NUT |

| 3 | 軸用鎖性扣環 CIRCLIPS FOR SHAFT |

| 4 | 內六角平端緊定螺釘 HEXAGON SOCKET SET SCREW WITH FLAT POINT |

| 5 | 內六角平端緊定螺釘 HEXAGON SOCKET SET SCREW WITH FLAT POINT |

| 6 | 螺旋母 NUT RING |

| 7 | 螺旋母 NUT |

| 8 | 鉛杆 LEAD SCREW |

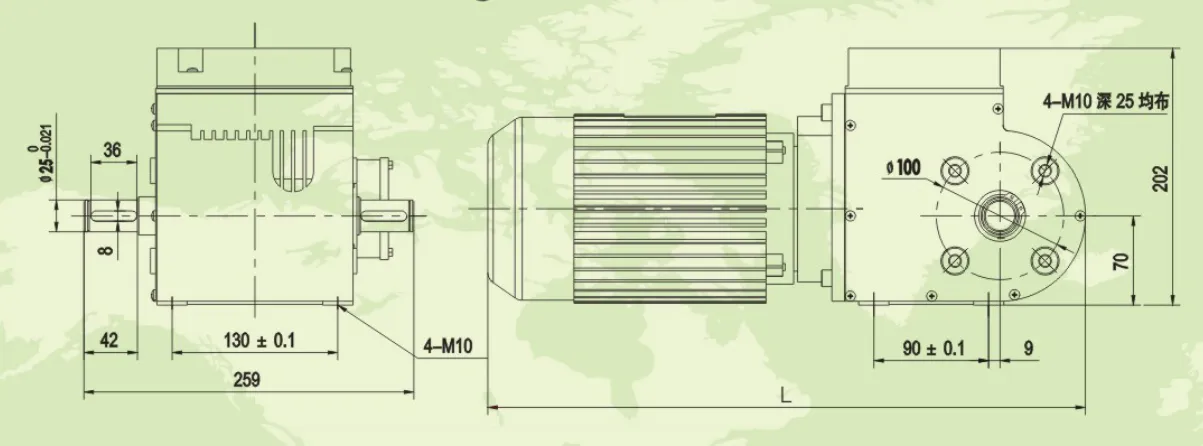

Product Dimension Drawing

| 功率 (KW) | 长度 (mm) | 重量 (kg) |

| 0.18 | 440 | 15 |

| 0.37 | 460 | 17 |

| 0.55/0.75 | 475 | 20 |

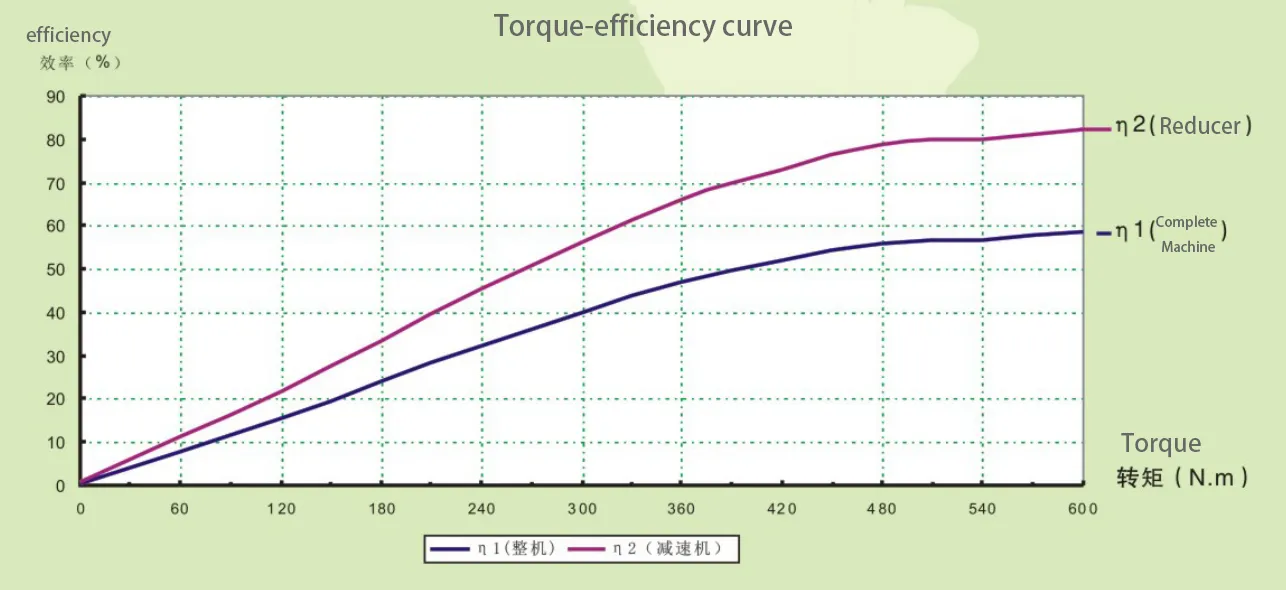

Ruducer Efficiency&Torque Graph

Reducer model:FMP-DWJC-50-500:1-0.55kW

Limit Instrustion

1. Tighten the two hexagonal set screws on the outer ring of the nut. When the screw rotates, the nut moves on the screw. When it moves to the end point, the nut will rotate with the screw. The long screw on the nut will move the spring to first open the switch FSQ1 (or ZSQ1) and the machine will stop.

2. If FSQ1 or ZSQ1 fails, the machine continues to rotate. The long screw will continue to move the spring to open FSQ2 (or ZSQ2) and the machine will stop. FSQ2 and ZSQ2 play a double insurance role.

3. Loosen the two hexagonal set screws to adjust the relative position of the nut on the screw to control the stop position.

FAQ And Solution

| Common faults | troubleshooting |

| After the greenhouse roll up motor is installed, it cannot move forward or backward | 1. Check whether the power supply and control lines are correctly installed according to the wiring diagram, and restart after confirming that there are no abnormalities.

2. Check whether the control power positioning is correct. The method is: observe the power direction of the installed drive and confirm whether the forward and reverse power are consistent with the drive direction. If they do not match, the forward and reverse directions will not move normally. After confirmation, you need to reinstall the drive or readjust the power direction. 3. Check the limit device to see if a switch is in the open state. If so, press the switch to position and restart. |

| After the reducer is restarted after running to the end, it cannot move forward or backward | 1. In this case, you should first open the switch device and find that one switch is in the disconnected state. Press the switch to locate it and restart.

2. If the switches are all pressed, check whether the drive contactor is released in time. If not, consider replacing the contactor. 3. When this kind of fault occurs, do not forcefully contact the contactor, forcibly start the power device, or cause damage to the reducer gears, or cause damage to the hard mechanical operation. |

| Perform lift | If the motor starts after the lift is started, it means that the motor is overloaded. Check whether each transmission structure is suitable for lifting and try to avoid the motor. |

| Limit failure | 1. Re-adjust the lifting position. 2. Re-wire and adjust the lifting position. 3. Check, repair and update |

| Excessive noise | 1. Add lubricating oil. 2. Re-tighten the screws. |