Specifications of Flail Mower Gearbox T-281A (1:2.91)

| Product Description |

Flail Mower Gearboxes – Replacement of Comer Gearbox T-281A 1:2.91

|

|---|---|

| Product details |

|

| Application range |

|

| Se compose de |

|

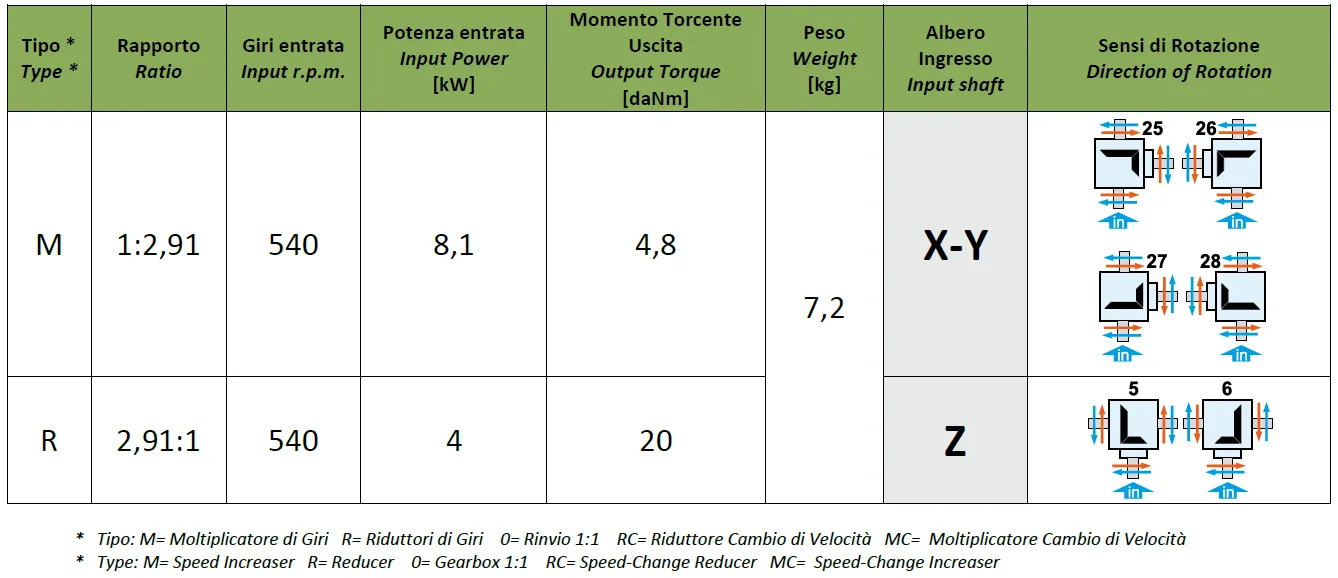

| Couple de sortie max. |

20 daNm

|

| Contient de l'huile |

Non

|

| Capacité d'huile maximale |

0.5 l

|

| Intervalle maximal de vidange d'huile |

500 h

|

| Grade de viscosité de l'huile SAE |

80W-90

|

| Matériau du boîtier |

Aluminium

|

| Poids |

7.2 kg

|

| Disposition des engrenages Croissante |

25 – 26 – 27 – 28

|

| Disposition des engrenages Réducteur |

5 – 6

|

| Puissance d'entrée kW / CV Croissante |

8.1 / 11 kW/HP

|

| Arbre d'entrée croissant |

X – Y

|

| Arbre d'entrée réducteur |

Z

|

| Puissance d'entrée KW / HP Réduction |

4 / 5 kW/HP

|

| Couple de sortie DaNm croissant |

4.8 daNm

|

| Ratio croissant |

1: 2.91

|

| Réduction du rapport |

2.91: 1

|

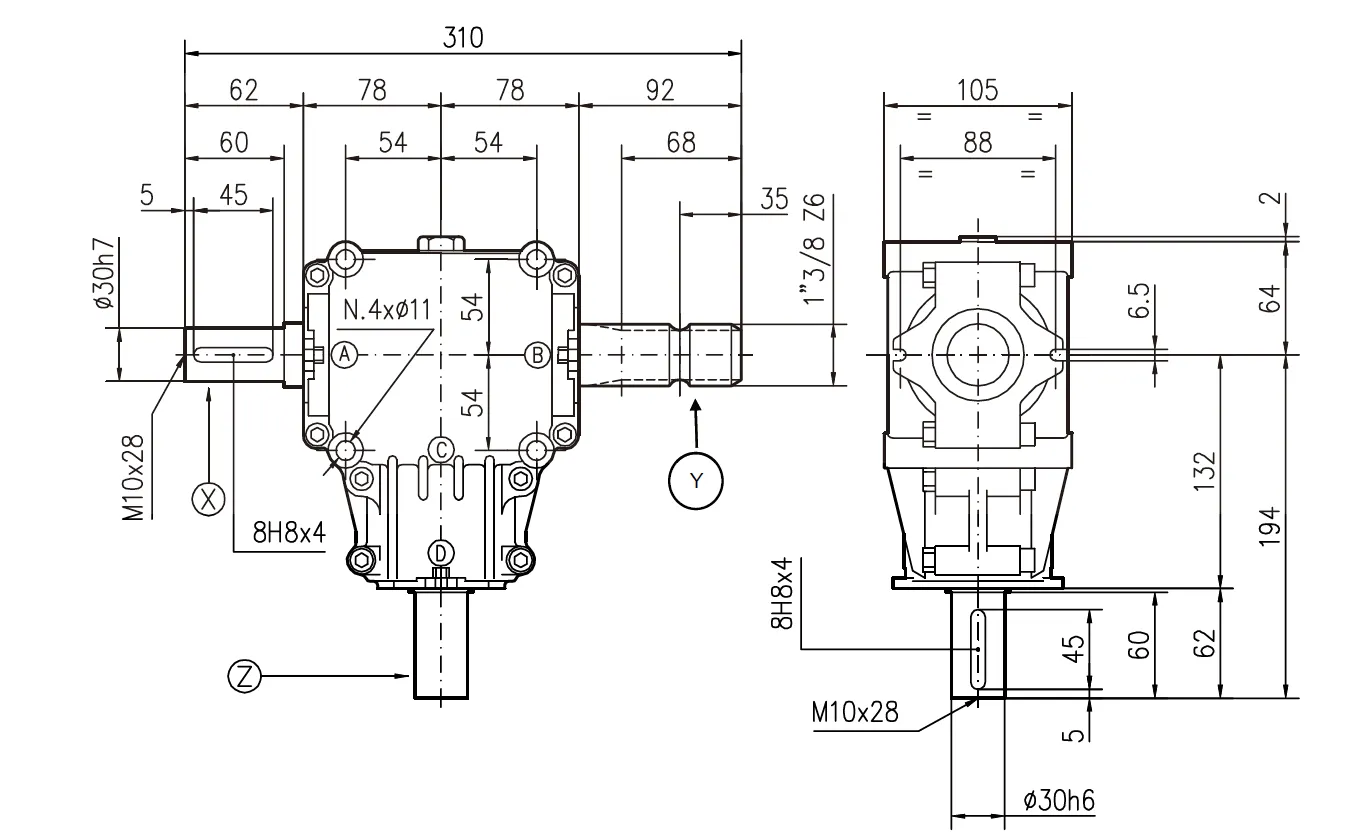

| Arbre X |

1 3/8″ (6) (A)

|

| Arbre Y |

1 3/8″ (6) (A)

|

| Arbre Z |

1 3/8″ (6) (E)

|

Benefits of Flail Mower Gearbox T-281A (1:2.91)

The Flail Mower Gearbox T-281A (1:2.91) is a high-performance gearbox designed specifically for flail mowers, offering significant advantages in agricultural, landscaping, and brush clearing applications. Its features and performance are tailored to ensure efficient operation, durability, and versatility. Below are the key benefits of the T-281A gearbox:

Transmission d'énergie efficace

The T-281A gearbox features a 1:2.91 gear ratio, which provides an excellent balance between speed reduction and torque increase. This gear ratio ensures that the flail mower blades rotate at the optimal speed for effective cutting, while the increased torque allows the mower to handle tougher vegetation, including dense grass, brush, and small shrubs. The efficient power transmission minimizes power loss, ensuring that the tractor’s engine operates at peak efficiency.

Durabilité et résistance

Built with high-quality materials such as hardened steel and precision-machined gears, the T-281A gearbox is designed to endure the demanding conditions of heavy-duty mowing. Whether operating in rough terrain or cutting through thick, tough vegetation, this gearbox offers superior durability. It can withstand high loads and harsh operational conditions without compromising its performance or longevity, reducing the need for frequent maintenance or replacements.

Smooth Operation and Low Maintenance

The T-281A gearbox is engineered for smooth operation with reduced friction, ensuring quieter and more stable performance. The high-quality bearings and precision gears minimize wear and tear, which translates to lower maintenance costs and extended operational life. Regular checks and lubrication are sufficient to maintain its efficiency, allowing operators to focus more on their work without worrying about constant gearbox issues.

Versatility in Applications

Thanks to its robust design and adjustable gear ratio, the T-281A gearbox is versatile enough to handle a variety of mowing tasks. Whether used for grass cutting, brush clearing, or landscaping, the gearbox adapts to different vegetation types and terrains. The 1:2.91 ratio ensures that the mower blades can effectively tackle challenging environments, making the gearbox an ideal choice for farms, estates, and commercial landscaping operations.

Compact and Easy to Install

The compact design of the T-281A gearbox allows for easy installation and compatibility with a wide range of flail mowers. Its simple, user-friendly structure reduces installation time, allowing operators to get the equipment up and running quickly. The gearbox is also designed for easy integration with standard PTO shafts, making it a convenient option for tractors and mowers across various industries. Additionally, the relatively small size of the gearbox does not add unnecessary weight to the mower, maintaining the machine’s maneuverability and efficiency.

The Flail Mower Gearbox T-281A (1:2.91) offers a highly efficient, durable, and versatile solution for operators who need reliable performance in demanding mowing applications. Its efficient power transmission, robust construction, low maintenance requirements, and adaptability to different cutting conditions make it a top choice for both agricultural and landscaping tasks. Whether you’re cutting thick brush, clearing land, or maintaining large estates, the T-281A gearbox provides a reliable, long-lasting, and cost-effective solution for all your flail mower needs.

|

|

Tractor PTO Shaft for Flail Mower Gearboxes

A Tractor PTO (Power Take-Off) Shaft is an essential component for transferring power from the tractor’s engine to the flail mower gearbox. The PTO shaft connects the tractor’s PTO system to the mower, ensuring that the mower blades receive the necessary rotational energy to operate effectively. Below are the key aspects and benefits of a PTO shaft for flail mower gearboxes:

Power Transmission from Tractor to Mower Gearbox

The primary function of the PTO shaft is to transmit the power generated by the tractor’s engine to the flail mower gearbox. The shaft connects to the tractor’s PTO drive and the mower’s input shaft, ensuring that the rotational power is properly transferred. The power from the tractor’s PTO is then converted by the gearbox to the appropriate speed and torque to drive the mower blades efficiently. This transmission of energy is crucial for the proper functioning of the flail mower in various agricultural tasks.

High Durability and Strength

PTO shafts for flail mower gearboxes are built to withstand high stress and heavy-duty operations. These shafts are typically made from high-strength steel and heat-treated for enhanced durability. The materials used ensure that the PTO shaft can handle the continuous high-torque demands of mowing, especially when cutting dense grass, brush, or small shrubs. The robustness of the PTO shaft ensures that it remains reliable over time, even under challenging working conditions.

Adjustable Length for Compatibility

Tractor PTO shafts are designed to be adjustable in length to accommodate various tractor and mower setups. The length of the PTO shaft can be easily adjusted by extending or shortening its telescoping sections. This flexibility ensures that the PTO shaft can be properly connected to different tractors with varying distances between the PTO drive and the mower gearbox, ensuring optimal power transfer and efficient operation.

Universal Joints for Smooth Operation

PTO shafts are equipped with universal joints (U-joints) at both ends, allowing the shaft to accommodate slight misalignments between the tractor’s PTO and the mower’s gearbox. These joints enable the shaft to maintain smooth power transmission even when the tractor and mower are not perfectly aligned, minimizing stress on the system and preventing premature wear. The U-joints allow the PTO shaft to flex, providing a stable connection between the tractor and the mower gearbox while reducing vibrations and noise.

Caractéristiques de sécurité

Safety is a key consideration in PTO shaft design. Many PTO shafts come equipped with safety shields or guards to prevent accidental contact with rotating parts. These guards cover the rotating shaft, protecting the operator from injury. Additionally, some PTO shafts are designed with shear bolts or torque limiters to prevent damage to the mower gearbox and tractor if the mower hits a large obstruction, such as a rock or debris. These safety mechanisms help prevent costly damage and keep operators safe during operation.

The Tractor PTO Shaft for Flail Mower Gearboxes is a vital component that ensures efficient and reliable operation of flail mowers. With its ability to transmit power effectively, robust construction, adjustable length, and safety features, the PTO shaft plays a critical role in achieving optimal mower performance. Proper maintenance, including lubrication and regular inspections, is essential for ensuring the longevity of the PTO shaft. Whether you are mowing large grass fields, clearing dense brush, or performing landscaping tasks, the PTO shaft provides the necessary power transfer to operate the flail mower efficiently and safely.

|

|

À propos de FMP

Basé en Italie, FMP est un fabricant leader reconnu pour son expertise dans la conception, le développement et la production de boîtes de vitesses hautes performances, principalement destinées au secteur des machines agricoles. Réputé pour sa précision, son innovation et sa fiabilité à toute épreuve, FMP s'est imposé comme un partenaire de confiance pour répondre aux exigences évolutives des marchés agricoles et industriels. Notre gamme complète de produits comprend des boîtes de vitesses spécialisées pour tondeuses à gazon, des arbres de prise de force et d'autres composants critiques, tous conçus pour offrir des solutions efficaces et personnalisées pour un large éventail d'applications.

Chez FMP, nous comprenons que chaque client a des besoins et des défis uniques. C'est pourquoi nous nous spécialisons dans la proposition de solutions sur mesure, qu'il s'agisse de composants individuels ou de systèmes entièrement intégrés. Nous adoptons une approche collaborative, en étroite collaboration avec nos clients, afin de garantir l'efficacité de chaque solution. Notre engagement à fournir des réponses rapides et professionnelles et des conseils d'experts garantit que chaque demande est traitée avec le plus grand soin et la plus grande précision, garantissant ainsi les meilleurs résultats pour nos clients.

Nous accordons une grande importance à une communication ouverte et continue, notamment lors du développement de nouveaux produits. Notre équipe dédiée travaille en étroite collaboration avec nos clients afin de comprendre parfaitement leurs besoins et de leur apporter des conseils et des recommandations précieux pour des solutions optimales. Qu'il s'agisse de concevoir des produits innovants ou d'honorer des commandes existantes, FMP s'engage à fournir des solutions de haute qualité, conçues avec précision et dans les délais impartis, garantissant ainsi à ses clients un service et des résultats optimaux.

Au cœur des activités de FMP se trouve notre souci constant de la qualité. Nous adhérons aux normes de fabrication les plus strictes et appliquons des mesures de contrôle qualité rigoureuses pour garantir que chaque produit réponde aux attentes de l'industrie, voire les dépasse. Cet engagement envers la qualité, associé à nos valeurs fondamentales d'intégrité, de travail d'équipe et de persévérance, nous a permis de bâtir des relations de confiance durables avec nos clients dans près de 30 pays à travers le monde.

FMP est toujours désireux de nouer des partenariats internationaux et s'engage à fournir des conseils d'experts et des solutions sur mesure pour répondre aux divers besoins de ses clients. Notre approche va au-delà de la simple livraison de produits ; nous visons à entretenir des relations durables qui contribuent à la réussite de chaque projet. Que vous ayez besoin de solutions innovantes pour une nouvelle entreprise ou d'un support continu pour un système existant, FMP est là pour relever vos défis techniques et vous accompagner dans la réussite de votre projet.

Auteur : CX