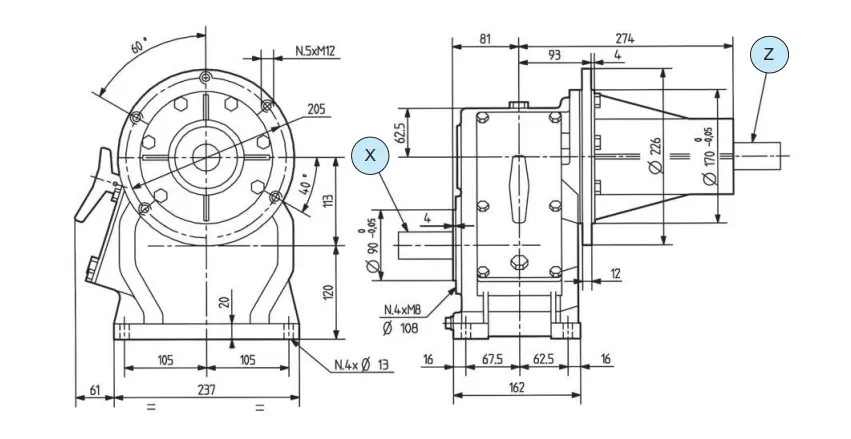

Specifications of Agricultural Sprayer Gearbox D21B/D21F

| i | N1[rpm] | P1[kW] | M2[Nm] | Shaft Type |

Input | |

X |

Z |

|||||

| 3.90 4.90 |

540 | 38.9 | – | 1” 3/8 Z6 | L270 35 | X |

| 3.60 4.50 |

540 | 40.5 | – | 1” 3/8 Z6 | L165 40 | X |

| 3.60 4.50 |

540 | 47.8 | – | 1” 3/8 Z6 | L286 40 | X |

| 2.90 3.90 |

540 | 41.2 | – | 1” 3/8 Z6 | L221 35 | X |

Key Components of Agricultural Sprayer Gearbox

The key components of an agricultural sprayer gearbox are critical for its function, durability, and efficiency in spraying operations. These components ensure the smooth transmission of power and facilitate optimal performance in agricultural tasks. The main components typically include:

- Input Shaft: The input shaft connects the gearbox to the power source, usually a tractor’s PTO (Power Take-Off). It transmits rotational power from the tractor to the gearbox, enabling the gearbox to operate.

- Gear Set (Helical or Spur Gears): The gear set is essential for transmitting rotational power from the input shaft to the output shaft. The gears are designed to provide the necessary speed and torque adjustments required for the sprayer’s pump or other associated mechanisms.

- Output Shaft: The output shaft transmits power to the sprayer components, such as the pump or spray arms. It is connected to the parts that control the application of the spray, driving them in a coordinated manner.

- Bearings and Seals: Bearings are used to reduce friction between moving parts, ensuring smooth rotation and preventing wear. Seals are critical for preventing oil leakage, contamination, and the entry of moisture, thereby extending the life of the gearbox.

- Housing: The gearbox housing encloses all internal components and provides structural integrity. It is designed to withstand high pressures, environmental conditions, and the mechanical stresses generated during operation.

- Lubrication System: The lubrication system ensures that the moving parts within the gearbox operate smoothly, reducing friction and preventing overheating. Proper lubrication is essential for extending the lifespan and efficiency of the gearbox.

- Overload Protection: Some agricultural sprayer gearboxes are equipped with overload protection features, such as shear pins or clutch mechanisms, to prevent damage to the gearbox in the event of unexpected resistance or operational stress.

These key components work together to ensure the gearbox efficiently transfers power, manages speed and torque, and supports the sprayer’s functionality. Regular maintenance and inspection of these components are crucial for optimal performance and durability.

Agricultural Applications of the Sprayer Gearbox

Agricultural sprayer gearboxes play a crucial role in various agricultural applications by ensuring efficient and precise spraying of fertilizers, pesticides, herbicides, and other chemicals. Here are some key agricultural applications where sprayer gearboxes are widely used:

- Crop Protection: Sprayer gearboxes are integral to the operation of sprayers used for crop protection. They enable the efficient application of pesticides, herbicides, fungicides, and insecticides. These gearboxes help maintain consistent pressure and flow, ensuring that the chemicals are evenly distributed across large fields, protecting crops from pests and diseases.

- Fertilization: Gearboxes in fertilizer spreader sprayers help control the flow and distribution of liquid fertilizers over farmland. They ensure that fertilizers are applied uniformly, which is essential for promoting healthy crop growth and optimizing yield. These systems are designed to handle various types of liquid fertilizers, providing precise application across different soil conditions.

- Weed Control: Agricultural sprayer gearboxes are used in sprayers designed for weed management. By delivering herbicides efficiently, these gearboxes enable the targeted control of weeds, reducing competition for nutrients and water in crops. This application is essential for improving crop productivity and reducing the need for manual labor.

- Post-Harvest Applications: Sprayer gearboxes are also employed in post-harvest treatments for crops. After harvest, sprayers may be used to apply protective coatings or preservatives to fruits, vegetables, and grains, enhancing their shelf life and preventing spoilage during transportation and storage.

- Field Irrigation and Chemical Mixing: Some sprayer gearboxes are part of irrigation systems, where they help mix and distribute chemicals such as growth regulators or fungicides along with water. These gearboxes ensure a uniform and controlled distribution of the solution over the crops, ensuring optimal growth conditions.

- Orchard and Vineyard Spraying: In specialized applications like orchards and vineyards, sprayer gearboxes are essential for applying treatments that protect crops from pests, diseases, and environmental stress. The gearboxes provide consistent power to the sprayer, ensuring accurate coverage of plants and trees in rows and varying terrains.

- Soil Treatment: In certain agricultural systems, sprayer gearboxes are used for soil treatment purposes, such as applying soil conditioners or pre-planting chemicals. These gearboxes ensure precise and even distribution of soil treatments, improving soil health and supporting better crop yields.

These diverse agricultural applications demonstrate the critical role of sprayer gearboxes in ensuring effective and efficient spraying processes. By delivering consistent power, accurate control, and reliable performance, sprayer gearboxes contribute to higher crop yields, improved pest and disease management, and better overall farm productivity.

À propos de FMP

Basé en Italie, FMP est un fabricant leader reconnu pour son expertise dans la conception, le développement et la production de boîtes de vitesses hautes performances, principalement destinées au secteur des machines agricoles. Réputé pour sa précision, son innovation et sa fiabilité à toute épreuve, FMP s'est imposé comme un partenaire de confiance pour répondre aux exigences évolutives des marchés agricoles et industriels. Notre gamme complète de produits comprend des boîtes de vitesses spécialisées pour tondeuses à gazon, des arbres de prise de force et d'autres composants critiques, tous conçus pour offrir des solutions efficaces et personnalisées pour un large éventail d'applications.

Chez FMP, nous comprenons que chaque client a des besoins et des défis uniques. C'est pourquoi nous nous spécialisons dans la proposition de solutions sur mesure, qu'il s'agisse de composants individuels ou de systèmes entièrement intégrés. Nous adoptons une approche collaborative, en étroite collaboration avec nos clients, afin de garantir l'efficacité de chaque solution. Notre engagement à fournir des réponses rapides et professionnelles et des conseils d'experts garantit que chaque demande est traitée avec le plus grand soin et la plus grande précision, garantissant ainsi les meilleurs résultats pour nos clients.

Nous accordons une grande importance à une communication ouverte et continue, notamment lors du développement de nouveaux produits. Notre équipe dédiée travaille en étroite collaboration avec nos clients afin de comprendre parfaitement leurs besoins et de leur apporter des conseils et des recommandations précieux pour des solutions optimales. Qu'il s'agisse de concevoir des produits innovants ou d'honorer des commandes existantes, FMP s'engage à fournir des solutions de haute qualité, conçues avec précision et dans les délais impartis, garantissant ainsi à ses clients un service et des résultats optimaux.

Au cœur des activités de FMP se trouve notre souci constant de la qualité. Nous adhérons aux normes de fabrication les plus strictes et appliquons des mesures de contrôle qualité rigoureuses pour garantir que chaque produit réponde aux attentes de l'industrie, voire les dépasse. Cet engagement envers la qualité, associé à nos valeurs fondamentales d'intégrité, de travail d'équipe et de persévérance, nous a permis de bâtir des relations de confiance durables avec nos clients dans près de 30 pays à travers le monde.

FMP est toujours désireux de nouer des partenariats internationaux et s'engage à fournir des conseils d'experts et des solutions sur mesure pour répondre aux divers besoins de ses clients. Notre approche va au-delà de la simple livraison de produits ; nous visons à entretenir des relations durables qui contribuent à la réussite de chaque projet. Que vous ayez besoin de solutions innovantes pour une nouvelle entreprise ou d'un support continu pour un système existant, FMP est là pour relever vos défis techniques et vous accompagner dans la réussite de votre projet.

Auteur : CX