The 10009 Customized Stainless Steel Mini Hydraulic Cylinder is a compact yet powerful solution designed for applications requiring precision and durability. Crafted from high-quality stainless steel, this mini hydraulic cylinder is resistant to corrosion and wear, making it ideal for both indoor and outdoor use.

Caractéristiques principales :

- Customizable Design:

Tailored to meet specific operational requirements, the 10009 mini hydraulic cylinder can be customized in terms of stroke length, bore size, and connection types to suit various applications. - Compact Size:

Its mini design allows for easy installation in tight spaces, making it perfect for machinery and systems where space is limited without compromising on performance. - Stainless Steel Construction:

Built from high-grade stainless steel, this cylinder offers exceptional resistance to corrosion and harsh environmental conditions, ensuring longevity and reliability. - High Performance:

Despite its small size, the hydraulic cylinder delivers impressive force and efficiency, making it suitable for a variety of applications, including automation, robotics, and material handling. - Versatile Applications:

The 10009 mini hydraulic cylinder is ideal for use in various industries, including manufacturing, automotive, and medical equipment, where precision and reliability are paramount.

Technical Specifications:

| Spécification | Description |

|---|---|

| Taille de l'alésage | Customizable |

| Stroke Length | Customizable |

| Maximum Pressure | Up to 3000 PSI |

| Matériel | High-quality stainless steel |

| Connection Type | Flanged, threaded, or custom |

Working Principle:

Working Principle:

The 10009 Customized Stainless Steel Mini Hydraulic Cylinder operates on the principle of hydraulic fluid pressure. When hydraulic fluid is pumped into the cylinder, it exerts pressure on the piston, generating linear movement. This mechanism allows for precise control and powerful action, making it essential for applications requiring accurate and reliable performance.

In summary, the 10009 Customized Stainless Steel Mini Hydraulic Cylinder is a versatile and efficient solution for various industrial needs. Its customizable features, durable stainless steel construction, and high performance make it an indispensable component for enhancing productivity and operational efficiency in diverse applications.

Unique Features

- Energy Saving:

The hydraulic cylinder is engineered to consume minimal energy during operation, which translates into significant cost savings over time. By optimizing power usage, this product not only reduces energy bills but also contributes to sustainability efforts by minimizing its environmental impact. This energy-efficient design makes it an economical choice for businesses looking to enhance their operational efficiency without compromising performance. - High Efficiency:

Designed for maximum productivity, the hydraulic cylinder operates at exceptionally high efficiency levels. Its advanced engineering ensures that it delivers consistent and reliable performance, allowing for faster cycle times and improved output. This high-efficiency operation is crucial in demanding industrial environments where every second counts, making it an invaluable asset for enhancing workflow and achieving production targets. - Safety:

Safety is a paramount consideration in the design of this hydraulic cylinder. It incorporates multiple safety features, including pressure relief valves, robust seals, and fail-safe mechanisms, to ensure secure operation under various conditions. These safety enhancements protect both the equipment and the operators, reducing the risk of accidents and downtime. By prioritizing safety, this product instills confidence in users, allowing them to operate machinery with peace of mind.

Avantages du cylindre de type T soudé

-

- Force accrue : Les vérins en T soudés sont réputés pour leur grande résistance, ce qui les rend adaptés aux applications nécessitant des levages lourds. Le procédé de soudage utilisé lors de leur fabrication garantit l'absence de points faibles et une résistance élevée aux pressions et aux contraintes.

La pression exercée sur le cylindre se répartit uniformément sur toute sa surface, ce qui le rend résistant à la déformation. Cette caractéristique garantit que le cylindre conserve sa forme et son intégrité structurelle même dans des conditions extrêmes.

-

- Prévention des fuites : Les vérins à té soudé sont conçus pour éviter les fuites. Le procédé de soudage utilisé lors de la fabrication garantit une étanchéité parfaite et une étanchéité parfaite. Cette caractéristique les rend adaptés aux applications où une fuite pourrait entraîner des dommages graves ou des blessures.

Les joints soudés sont lisses, sans crevasses ni rainures où des débris ou de la saleté peuvent s'accumuler, réduisant ainsi le risque de corrosion et d'endommagement du cylindre.

-

- Personnalisable : Les vérins en T soudés peuvent être personnalisés pour répondre à des applications spécifiques. Disponibles en différentes tailles et formes, ils peuvent être fabriqués pour répondre aux exigences spécifiques de chaque application.

Le processus de personnalisation permet d'optimiser les performances du vérin, garantissant ainsi son adéquation à l'application prévue. Cette caractéristique rend les vérins à té soudé idéaux pour diverses applications industrielles, notamment la construction, l'exploitation minière et la manutention.

-

- Rentable : Les vérins à té soudé sont plus économiques que les autres types de vérins. Leur procédé de fabrication est simple, ce qui les rend moins coûteux.

De plus, la résistance et la durabilité élevées des vérins en T soudés réduisent les réparations et remplacements fréquents, réduisant ainsi les coûts de maintenance. Cette caractéristique en fait un choix populaire pour de nombreuses industries, notamment celles disposant d'un budget limité.

-

- Efficacité accrue : Les vérins à té soudé sont très performants. Leur conception garantit que la force appliquée est transmise directement à la charge, réduisant ainsi les pertes d'énergie et augmentant l'efficacité.

Les joints soudés sont robustes et rigides, minimisant la déflexion et garantissant la stabilité structurelle du vérin, même dans des conditions extrêmes. Cette caractéristique rend les vérins à té soudé idéaux pour les applications exigeant une efficacité et une fiabilité élevées.

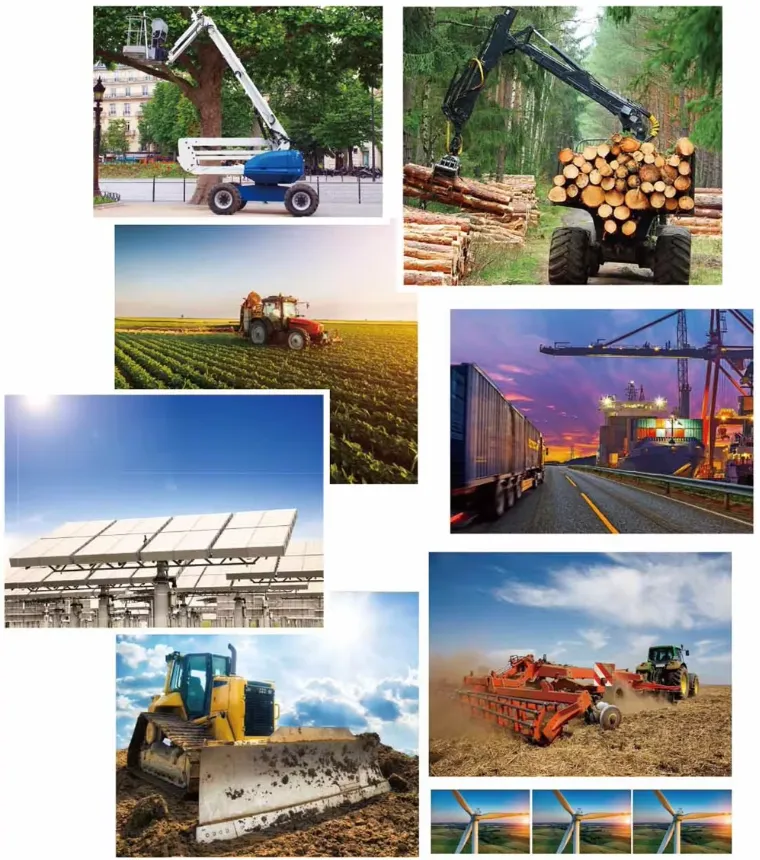

Application du cylindre de type T soudé

-

Automotive Industry

Welded Tee Type Cylinders are widely used in the automotive industry. They are used in car doors, hood and trunk lifts, convertible roofs, and power steering systems. These cylinders are preferred because of their ability to provide a high force output with low space requirements. The Tee Type cylinder design is well suited for applications where the force needs to be transferred in two different directions.

Furthermore, the welded construction of these cylinders allows them to operate at high temperatures and pressures without any leaks. This makes them suitable for use in engines, transmissions, and braking systems.

-

Manufacturing Industry

Welded Tee Type Cylinders are also used in the manufacturing industry. They are used in hydraulic presses, forging machines, and metal cutting machines. The high force output of these cylinders makes them ideal for applications where a lot of force is required in a small space.

The Tee Type cylinder design is also well-suited for applications where the force needs to be transferred in two different directions. For example, in a hydraulic press, the Tee Type cylinder can be used to apply force both vertically and horizontally, allowing for more complex manufacturing processes.

-

Aerospace Industry

Welded Tee Type Cylinders are used in the aerospace industry for a variety of applications. They are used in landing gear systems, cargo doors, and flight control systems. The high force output and compact design of these cylinders make them ideal for use in the limited space available on an aircraft.

The welded construction of these cylinders also makes them resistant to the high pressures and temperatures experienced during flight. Additionally, the Tee Type cylinder design allows for force to be transferred in two different directions, making it well-suited for applications where the force needs to be applied at an angle.

-

Construction Industry

Welded Tee Type Cylinders are used in the construction industry for heavy lifting and moving applications. They are used in cranes, excavators, and backhoes. The high force output and compact design of these cylinders make them ideal for use in the limited space available on a construction site.

The Tee Type cylinder design allows for force to be transferred in two different directions, making it well-suited for applications where the force needs to be applied at an angle. Additionally, the welded construction of these cylinders allows them to operate at high pressures and temperatures without any leaks, making them suitable for use in harsh outdoor environments.

À propos de FMP

FMP has been a leading manufacturer and supplier of Hydraulic Cylinders for over 30 years. Our industrial area is located in Italy and we have more than 100 equipment, including automatic gas shielded welding machine, deep hole boring machine, CNC lathe, cylindrical grinder, automatic cleaning machine, automatic installation machine, automatic hydraulic cylinder performance test bench, automatic painting line and more.

Our Hydraulic Cylinders are designed and processed with strict quality control to ensure we deliver only the best to our customers. Our services include:

- Service de conception : Our experienced design team can support you with any new product needs or improvements you may want.

- Service produit : We ensure quality throughout the entire process of raw materials selection, cutting, rough processing, testing, cleaning, assembly, packaging, and transportation.

- Exemple de processus : We can develop and constantly modify samples according to your specific requirements.

- R&D : We study new market needs and develop new models accordingly.

- Personnalisation : We accept customization requests for all types of Hydraulic Cylinders.

Our commitment to quality and customer satisfaction sets us apart from other manufacturers. We strive to provide the best products and services to meet your needs.

Auteur : CX