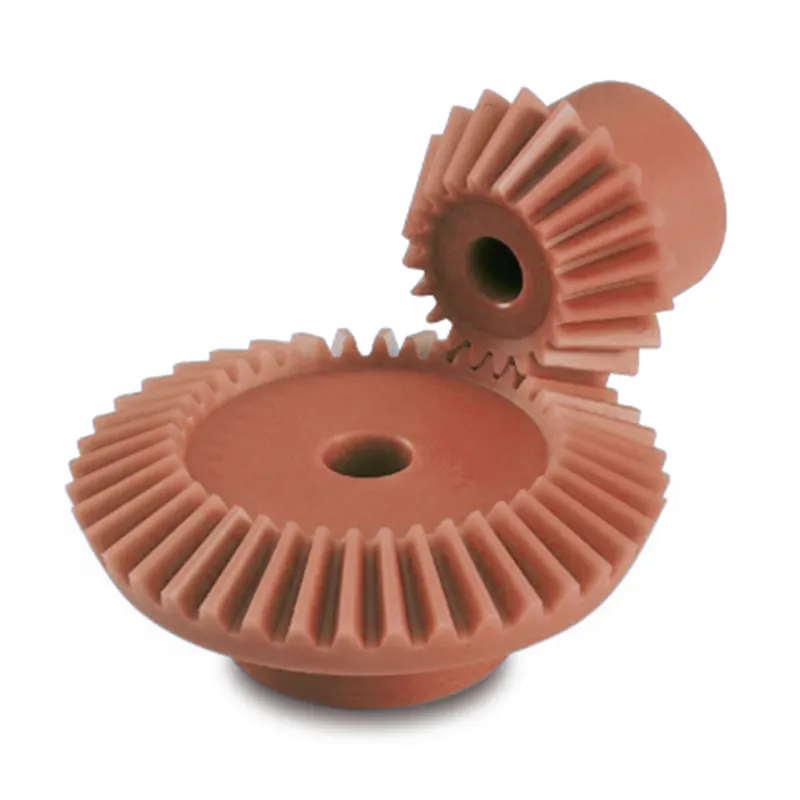

Plastic Bevel Gears Description

Dimension:Φ12

Module: M0.25

Material Type: Plastic, POM, Nylon…as the customer required

Ratios: 1:1, 2:1, 3:1, 4:1, 5:1

Operating temperature: -40°C to 80°C

|

|

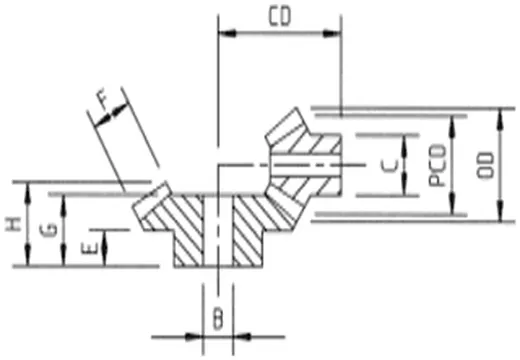

| Part no (Link) |

Pitch (mod) |

No. of Teeth |

All dimensions in mm | Brass Insert et Set Screw |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Outside Dia. |

Pitch Dia. |

Bore Dia. “B” |

‘CD’ | Hub dia ‘C’ |

Boss Length ‘E’ |

Tooth Width ‘F’ |

Length ‘G’ |

Length ‘H’ |

||||

| 1:1 Ratio | ||||||||||||

| GB05M016 | 0.5 | 16 | 8.7 | 8.0 | 3.0 | 10.5 | 7.0 | 6.0 | 2.0 | 8.0 | 8.0 | |

| GB1M016 | 1 | 16 | 17.6 | 16 | 5.0 | 18.4 | 12.0 | 8.0 | 4.7 | 13.6 | 13.6 | |

| GB1M016BS | 1 | 16 | 17.6 | 16 | 5.0 | 18.4 | 16.0 | 8.0 | 4.7 | 13.6 | 13.6 |  |

| 2:1 Ratio | ||||||||||||

| GB1M215030 | 1 | 15 | 16.8 | 15.0 | 5.0 | 26.4 | 12.2 | 10.6 | 6.6 | 17.0 | 17.0 | |

| 30 | 31.1 | 30.0 | 8.0 | 20.9 | 18.0 | 9.1 | 6.6 | 14.8 | 16.2 | |||

| GB1M215030BS | 1 | 15 | 16.8 | 15.0 | 5.0 | 26.4 | 16.0 | 10.6 | 6.6 | 17.0 | 17.0 |  |

| 30 | 31.1 | 30.0 | 4.0 | 20.9 | 18.0 | 9.1 | 6.6 | 14.8 | 16.2 |  |

||

| 3:1 Ratio | ||||||||||||

| GB1M315045 | 1 | 15 | 16.6 | 15.0 | 5.0 | 34.3 | 12.3 | 11.0 | 9.2 | 20.4 | ||

| 45 | 46.1 | 45.0 | 10.0 | 22.7 | 23.4 | 9.6 | 9.2 | 16.5 | 18.2 | |||

| GB1M315045BS | 1 | 15 | 16.6 | 15.0 | 5.0 | 34.3 | 16.0 | 11.0 | 9.2 | 20.4 |  |

|

| 45 | 46.1 | 45.0 | 6.0 | 22.7 | 23.4 | 9.6 | 9.2 | 16.5 | 18.2 |  |

||

| 4:1 Ratio | ||||||||||||

| GB1M410040 | 1 | 10 | 12.0 | 10.0 | 4.0 | 30.1 | 7.8 | 9.3 | 8.2 | 17.7 | ||

| 40 | 40.8 | 40.0 | 10.0 | 20.1 | 23.4 | 10.8 | 8.2 | 15.7 | 17.0 | |||

| GB1M410040BS | 1 | 10 | 12.0 | 10.0 | 4.0 | 30.1 | 12.7 | 9.3 | 8.2 | 17.7 |  |

|

| 40 | 40.8 | 40.0 | 6.0 | 20.1 | 23.4 | 10.8 | 8.2 | 15.7 | 17.0 |  |

||

| 5:1 Ratio | ||||||||||||

| GB1M512060 | 1 | 12 | 13.7 | 12.0 | 4.0 | 40.5 | 9.5 | 10.0 | 9.5 | 20.3 | ||

| 60 | 60.4 | 60 | 10.0 | 21.0 | 20.5 | 11.0 | 9.5 | 15.5 | 17.4 | |||

| GB1M512060BS | 1 | 12 | 13.7 | 12.0 | 4.0 | 40.5 | 14.3 | 10.0 | 9.5 | 20.3 |  |

|

| 60 | 60.4 | 60 | 6.0 | 21.0 | 20.5 | 11.0 | 9.5 | 15.5 | 17.4 |  |

||

| GB1M512* | 1 | 12 | 13.7 | 12.0 | 4.0 | 40.5 | 9.5 | 10.0 | 9.5 | 20.3 | ||

| GB1M512BS* | 1 | 12 | 13.7 | 12.0 | 4.0 | 40.5 | 14.3 | 10.0 | 9.5 | 20.3 |  |

|

| *NB: These gears match with 60 tooth bevel gear only. Their geometry is not compatible with other gears. | ||||||||||||

Plastic Bevel Gears Specification

| Plastic Bevel Gear | |

| Dimension | Φ3mm- Φ120mm |

| Module | M0.15, M0.2, M0.25-M0.8, M0.8<M<M1.0 M1.5<M<M2.0 |

| Material Type | POM, PA, PPA, PBT PEEK as Customized |

| Meshing Grade | GB 6, ISO 6, JGMA 1, JIS 6, AGMA 13, DIN 6,DIN5 |

| Application | Medical, Industrial, Automotive, Military, Aircraft, Mechanical, Auto |

| Customized | ODM/OEM |

| Sample | Sample available |

| Modes of Packing | Vacuum-packed with Plastic Tray |

| Modes of Delivery | DHL & TNT & FedEx & UPS |

| Certificate | ISO 9001: 2008/TS16949 |

Features of Plastic Bevel Gears

- Lightweight Construction: Plastic bevel gears are significantly lighter than their metal counterparts due to the use of materials like nylon, acetal, or polycarbonate. This reduces the overall weight of machinery and improves efficiency in applications where weight is a concern.

- Résistance à la corrosion: Unlike metal gears, plastic bevel gears are highly resistant to corrosion and rust, making them ideal for use in humid, wet, or chemically aggressive environments without requiring additional protective coatings.

- Low Noise Operation: The inherent damping properties of plastic materials result in quieter operation compared to metal gears. This makes them suitable for applications where noise reduction is a priority, such as in household appliances or office equipment.

- Cost-Effective Production: Plastic bevel gears can be mass-produced using injection molding or other economical manufacturing processes, leading to lower production costs and making them an affordable choice for many industries.

- Self-Lubricating Properties: Many plastic materials used in bevel gears, such as nylon or PTFE-infused plastics, have natural lubricity, reducing the need for external lubrication and minimizing maintenance requirements in mechanical systems.

Applications of Plastic Bevel Gears

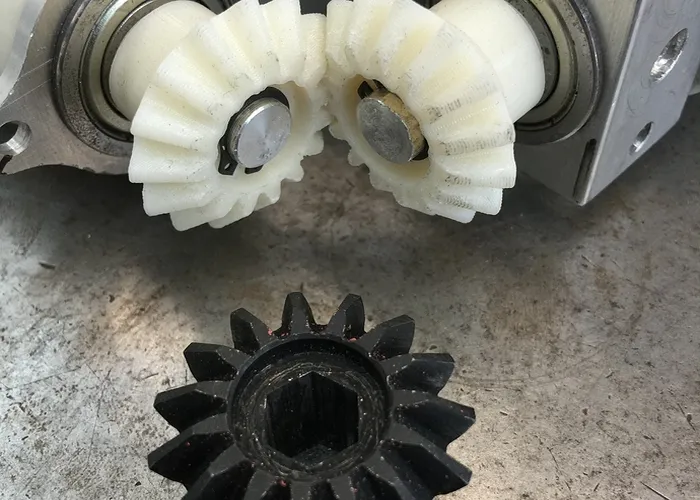

Plastic bevel gears, while less strong than steel gears, offer wear resistance and quiet operation. They are ideal for:

- Office Automation Equipment: Used in printers and copiers for smooth, silent drive systems.

- Electronic Goods Loaders: Found in DVD players and small appliances for reliable, lightweight motion.

- Toys: Common in toy cars and robots, balancing cost, durability, and low noise.

Their strengths suit lighter-duty uses where efficiency outweighs the need for high strength.

|

|

Fournisseur d'engrenages coniques en plastique

FMP propose tous les engrenages en plastique dont vous avez besoin. Nous proposons des engrenages droits, des crémaillères, des engrenages hélicoïdaux et coniques, des vis sans fin, des engrenages coniques, des pignons et des crémaillères en plastique.

Appelez-nous pour obtenir de l'aide afin de trouver le bon équipement ou la modification d'un article de catalogue standard ou d'une conception personnalisée ; nos ingénieurs fourniront la meilleure solution pour votre application.

À propos de FMP

FMP est un fabricant italien leader d'engrenages et de crémaillères, reconnu pour son expertise dans la production de composants standards et de solutions sur mesure. Outre sa gamme de pièces standard, FMP est spécialisé dans la fabrication d'engrenages standards et spécialisés à partir de plans ou d'échantillons fournis par ses clients. Nos engrenages sont disponibles dans une variété de matériaux, notamment l'acier au carbone, l'acier inoxydable, l'aluminium, le cuivre, le laiton et le plastique, avec des configurations hélicoïdales ou cylindriques. Pour toute demande d'engrenages personnalisés, n'hésitez pas à nous contacter par e-mail. L'équipe d'ingénieurs professionnels de FMP répondra à votre demande sous 24 heures.