Choosing the Right CNC Spindle Motor Type

Selecting the appropriate CNC spindle motor is essential for optimizing performance, precision, and efficiency in machining operations. The right motor ensures the machine can handle the required workload while achieving the desired output quality. Here are key factors to consider when choosing a CNC spindle motor:

- Power and Torque Requirements

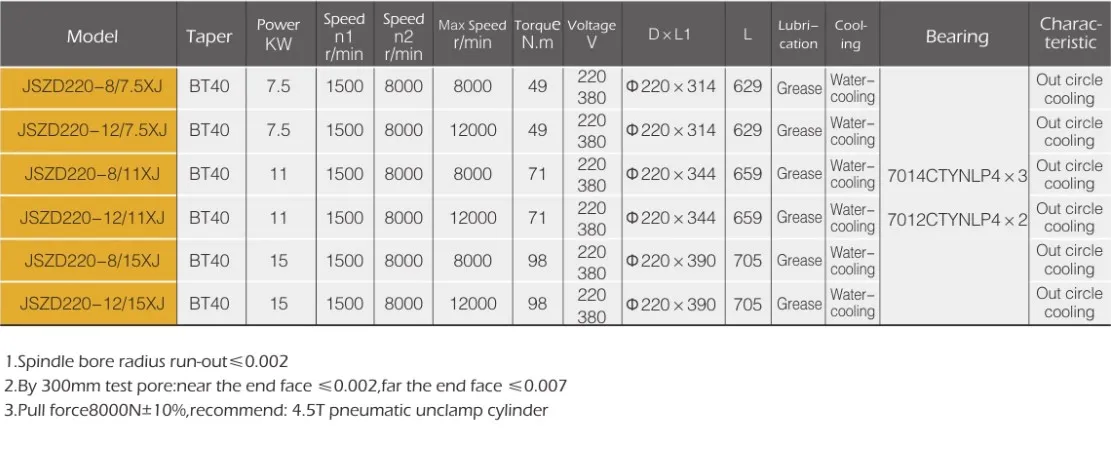

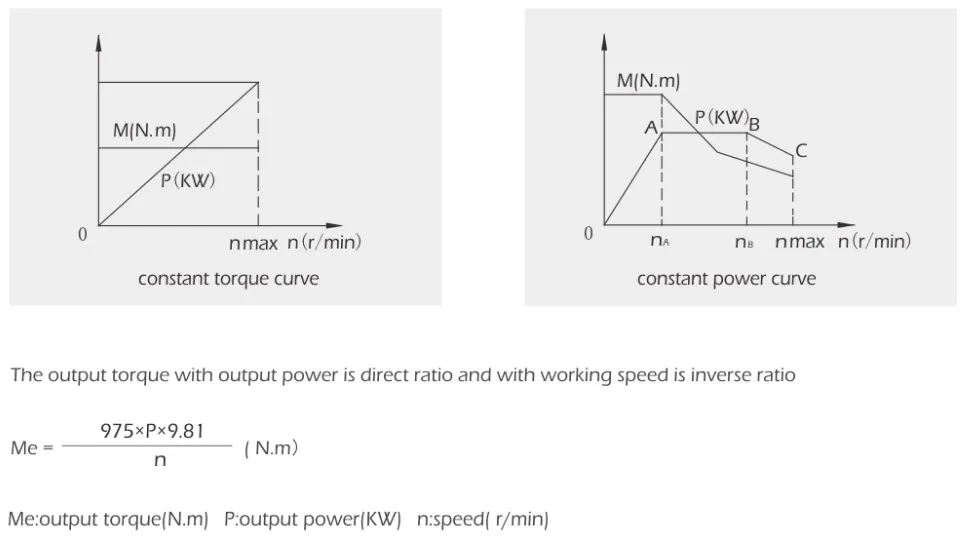

The motor’s power (measured in horsepower or kilowatts) and torque ratings directly impact its ability to handle different materials and cutting operations. For heavy-duty applications, such as milling or deep cutting, a high-torque motor is necessary. For finer, precision work, lower power motors with high-speed capabilities may be more appropriate. Assess the specific machining tasks to determine the required motor power and torque. - Speed Range and Control

CNC spindle motors are available in a wide range of speeds, typically measured in revolutions per minute (RPM). Some applications require high-speed spindles for processes like drilling or engraving, while others, such as threading or rough cutting, may demand lower speeds with higher torque. The motor should have variable speed control to adjust the spindle’s RPM for different materials and operations, ensuring versatility and optimizing performance. - Cooling System

Spindle motors generate heat during operation, especially in high-power or continuous use scenarios. Choosing a motor with an appropriate cooling system, such as air or liquid cooling, helps to maintain optimal performance and prevent overheating. Liquid-cooled spindles are typically more efficient for long-duration or high-power tasks, while air-cooled motors are often sufficient for light-duty applications. - Precision and Runout

The precision of the spindle motor is critical for high-accuracy machining. Motors with low runout (the amount of deviation from true rotational axis) ensure that the workpiece is held securely and rotates uniformly, leading to better dimensional accuracy and surface finishes. High-precision spindles are essential for industries requiring tight tolerances, such as aerospace or medical device manufacturing. - Motor Type: AC vs. DC

CNC spindle motors are generally either AC (alternating current) or DC (direct current). AC motors are typically preferred for industrial CNC applications due to their reliability, better power efficiency, and longer lifespan. They are ideal for high-speed and high-torque operations. DC motors, while offering excellent torque at low speeds, are often more suitable for smaller or more specialized CNC machines with lower power demands.

Selecting the right CNC spindle motor requires a balance of factors, including power, speed, cooling, precision, and compatibility with the machine’s control system. By carefully considering these factors, manufacturers can choose a spindle motor that enhances the CNC machine’s performance, improves machining efficiency, and delivers the desired quality for specific applications.

Il existe deux manières d'obtenir la sortie : l'une est le couple constant et l'autre est la puissance constante comme ci-dessous :

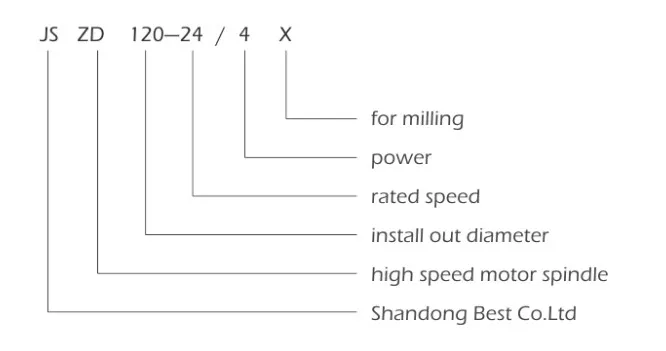

Explication de la nomenclature de la broche du moteur

La fin de la connexion de la broche

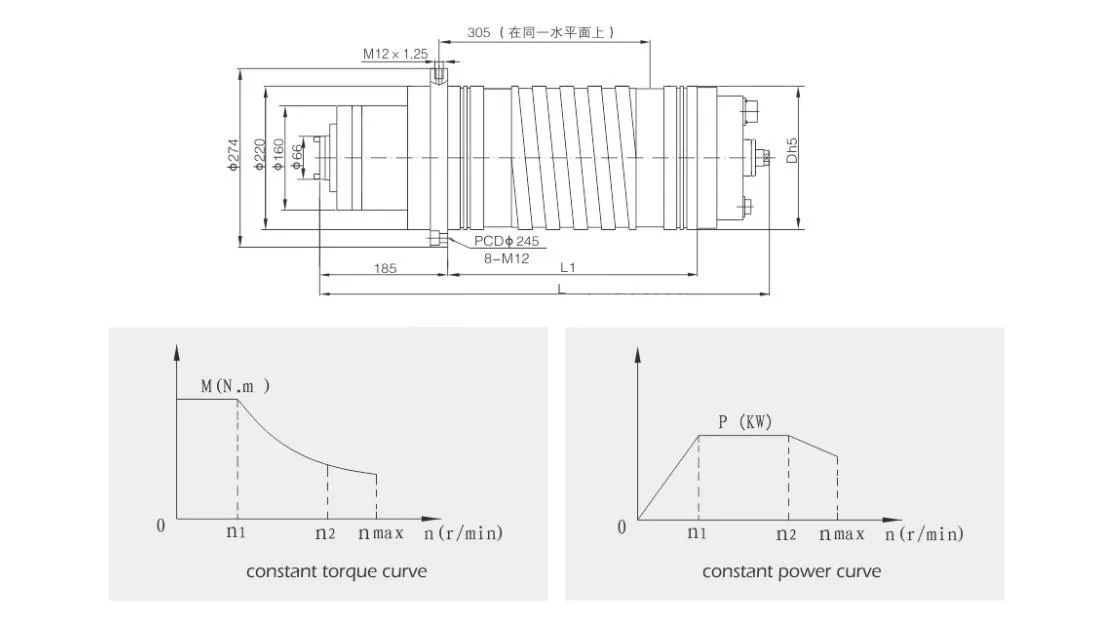

Il existe de nombreux types de connexion différents, en fonction du modèle de broche différent, veuillez vous référer au tableau ci-dessous.

Instructions de broche

2. Électrique broche est généralement refroidi par circulation d'eau. Eau de refroidissement doit être inoxydable et filtré propre. Quand acquérir l'eau, l'entrée doit être sous le électrique broche.

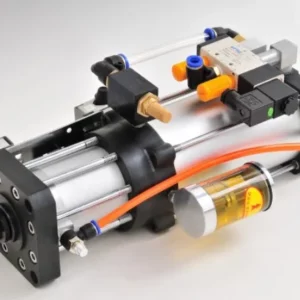

trois. Quand travailler avec une broche lubrifiée par brouillard d'huile, la stresser vanne de régulation sur le brouillard d'huile gadget devrait être réglé à 0,25~0,3 MPA le brouillard pression devrait être 0,1 à 0,2 MPA et le variété de gouttes d'huile doit être 60-70 gouttes/min. et aussi le huile de graissage devrait être huile de cloche ou huile de turbine n° 20.

quatre. Le vitesse autour du broche motorisée guide est définitivement le le plus élevé vitesse, et ça peut ne pas être élevé, néanmoins, il peut être employé réduire

le rythme, la tension et la fréquence sont réduit une fois que le vitesse est abaissé.

5. La rotation cours avec le broche motorisée est généralement dans le sens inverse des aiguilles d'une montre (vu dans le arbre). sauf pour exclusif

demandes.

6. La broche motorisée lubrifiée par brouillard d'huile doit être lié avec de l'eau et essence avant il se pourrait que ce soit possible commencer et cesser l'eau et carburant fournir après fermer.

Explication: unique opération est requis selon au électrique broche lignes directrices.

Auteur : CX