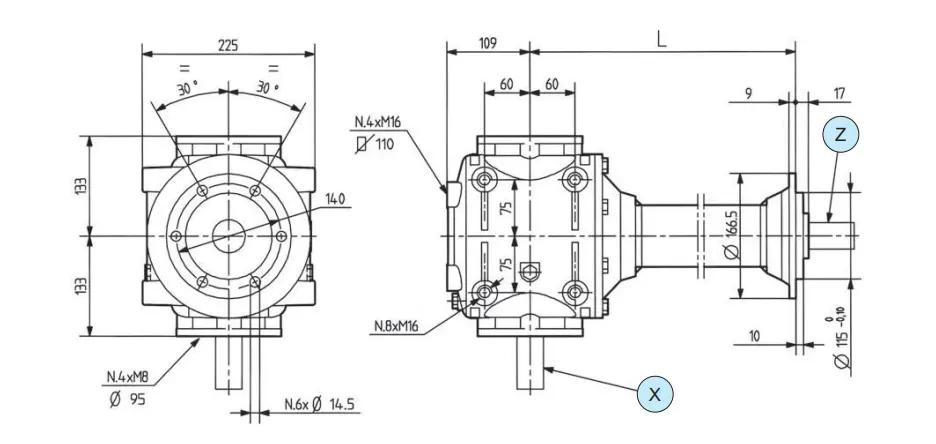

Rotary Tiller Gearbox TLZ-292A Specifications

| i | 1.86 |

| N1[rpm] | 540 |

| P1[kW] | 47.8 |

| M2[Nm] | 1525 |

Arbre X |

1” 3/8 Z6 |

Arbre Z |

42*48 |

| Input | X |

Features of the Rotary Tiller Gearbox TLZ292A

The Rotary Tiller Gearbox TLZ292A is designed to offer high performance, durability, and reliability for use in agricultural machinery, particularly in rotary tillers. Below are the key features of this gearbox:

Heavy-Duty Construction

The TLZ292A gearbox is built with a robust, heavy-duty design to withstand the demanding conditions of agricultural operations. It is constructed using high-quality materials that ensure longevity and superior resistance to wear, even under heavy workloads.

High Efficiency Transmission

The gearbox is engineered for optimal power transmission, ensuring efficient operation of the tiller blades. It provides smooth and consistent power flow, allowing for improved soil penetration and tilling performance. The high-efficiency design minimizes energy loss and enhances the overall productivity of the rotary tiller.

Conception compacte et légère

Despite its powerful performance, the TLZ292A gearbox boasts a compact and lightweight structure. This makes it easy to handle, install, and maintain, while also helping to reduce the overall weight of the tilling system for improved maneuverability and fuel efficiency.

Superior Heat Dissipation

The gearbox is equipped with a cooling system designed to maintain an optimal operating temperature. The enhanced heat dissipation mechanism ensures that the gearbox operates at peak performance for extended periods without overheating, thus improving the overall reliability and lifespan of the gearbox.

Adjustable PTO Shaft Compatibility

The TLZ292A gearbox is compatible with a variety of PTO shafts, allowing for easy integration with different tractor models. It features adjustable PTO input options, ensuring flexibility and compatibility with a wide range of agricultural machinery.

In summary, the Rotary Tiller Gearbox TLZ292A is a high-performance, durable, and reliable solution for agricultural tilling needs. Its efficient transmission, robust construction, and low maintenance requirements make it an excellent choice for farmers looking to enhance productivity and ensure long-term operational reliability.

Structural Components of the Rotary Tiller Gearbox TLZ292A

The Rotary Tiller Gearbox TLZ292A consists of several key structural components designed for durability, efficiency, and ease of use in demanding agricultural applications. Below is a description of the main components:

Input Shaft and PTO Connection

The input shaft of the TLZ292A gearbox is connected to the tractor’s power take-off (PTO) system. This component transmits power from the tractor’s engine to the gearbox, driving the rotary tiller’s blades. The PTO connection is designed for easy integration with different tractor models, offering flexibility and ensuring efficient power transfer to the gearbox.

Reduction Gears

The gearbox includes precision-engineered reduction gears that reduce the high-speed input from the PTO to a lower, more suitable speed for the tiller blades. These gears ensure that the tiller operates efficiently, providing the necessary torque for optimal soil penetration and tilling performance while minimizing energy loss.

Bearings and Bushings

To ensure smooth and reliable operation, the TLZ292A gearbox is equipped with high-quality bearings and bushings. These components reduce friction between moving parts, ensuring smooth gear transitions and preventing wear and tear. The durable bearings also extend the lifespan of the gearbox, enabling it to perform effectively under heavy-duty conditions.

Housing and Enclosure

The housing of the TLZ292A gearbox is made from high-strength materials to provide robust protection for the internal components. The durable housing safeguards the gearbox’s gears, shafts, and bearings from environmental elements like dust, dirt, moisture, and impact. Additionally, the housing features a corrosion-resistant coating, which enhances its durability and protects it from rust and other forms of damage.

Output Shaft and Tiller Blade Connection

The output shaft connects the gearbox to the rotary tiller’s blades. It is designed to transfer the reduced power from the gearbox to the tiller blades, driving them to rotate at the appropriate speed and torque. The output shaft’s design ensures reliable performance and efficient power transmission, contributing to the overall effectiveness of the tilling process.

The Rotary Tiller Gearbox TLZ292A features key structural components like the input shaft, reduction gears, bearings, housing, and output shaft, all working together to deliver high efficiency, reliability, and longevity in agricultural tilling applications.

Working Principle of the Tractor PTO Driven Rotary Tiller Gearbox

The working principle of the Tractor PTO Driven Rotary Tiller Gearbox revolves around efficiently transferring power from the tractor’s engine to the rotary tiller blades, allowing the machine to perform soil tilling operations. Here’s how the gearbox works in five key steps:

Power Transfer from Tractor PTO to Gearbox

The process begins when the tractor’s engine powers the PTO shaft (Power Take-Off), which is connected to the gearbox input shaft. The PTO shaft is designed to rotate at high speeds, typically ranging from 540 to 1000 RPM, depending on the tractor’s engine output. This rotational power is transferred directly to the gearbox, which serves as the intermediary mechanism between the tractor and the tiller blades.

Speed Reduction through Reduction Gears

Once the power enters the gearbox, it passes through a set of reduction gears. These gears reduce the high rotational speed of the PTO shaft to a much lower, more suitable speed for the tiller blades. The reduction gearing ensures that the blades operate at optimal speeds, providing the necessary torque for effective soil cutting and penetration.

Torque Amplification for Tilling Efficiency

The reduced speed from the gearbox is paired with an increase in torque, which is essential for tilling heavy or compacted soil. This increased torque enables the tiller blades to dig deeper into the ground, breaking up soil and aerating it effectively. The gearbox ensures the proper balance of speed and torque for maximum tilling efficiency, depending on the soil conditions.

Output Shaft Drives the Tiller Blades

The output shaft of the gearbox is connected to the rotary tiller blades. As the gearbox reduces the PTO input speed and increases torque, the output shaft rotates at a lower but more powerful speed. This rotation drives the blades of the tiller, causing them to spin and cut through the soil. The tiller blades are typically arranged in a spiral pattern, enabling them to cover the soil evenly and consistently.

Continuous Power Flow and Smooth Operation

The gearbox ensures a continuous flow of power from the tractor’s PTO to the tiller blades. The design of the gearbox helps maintain consistent operation, even under varying loads, by optimizing the distribution of power. It also minimizes energy loss, ensures smooth transitions between gears, and reduces wear on critical components, allowing the tiller to operate efficiently over extended periods.

The PTO driven rotary tiller gearbox works by transferring high-speed power from the tractor’s PTO, reducing and adjusting the speed and torque, and then delivering controlled power to the tiller blades for effective soil tilling. The gearbox’s role in optimizing speed, torque, and power flow is critical for the performance and durability of the rotary tiller.

À propos de FMP

Basé en Italie, FMP est un fabricant leader reconnu pour son expertise dans la conception, le développement et la production de boîtes de vitesses hautes performances, principalement destinées au secteur des machines agricoles. Réputé pour sa précision, son innovation et sa fiabilité à toute épreuve, FMP s'est imposé comme un partenaire de confiance pour répondre aux exigences évolutives des marchés agricoles et industriels. Notre gamme complète de produits comprend des boîtes de vitesses spécialisées pour tondeuses à gazon, des arbres de prise de force et d'autres composants critiques, tous conçus pour offrir des solutions efficaces et personnalisées pour un large éventail d'applications.

Chez FMP, nous comprenons que chaque client a des besoins et des défis uniques. C'est pourquoi nous nous spécialisons dans la proposition de solutions sur mesure, qu'il s'agisse de composants individuels ou de systèmes entièrement intégrés. Nous adoptons une approche collaborative, en étroite collaboration avec nos clients, afin de garantir l'efficacité de chaque solution. Notre engagement à fournir des réponses rapides et professionnelles et des conseils d'experts garantit que chaque demande est traitée avec le plus grand soin et la plus grande précision, garantissant ainsi les meilleurs résultats pour nos clients.

Nous accordons une grande importance à une communication ouverte et continue, notamment lors du développement de nouveaux produits. Notre équipe dédiée travaille en étroite collaboration avec nos clients afin de comprendre parfaitement leurs besoins et de leur apporter des conseils et des recommandations précieux pour des solutions optimales. Qu'il s'agisse de concevoir des produits innovants ou d'honorer des commandes existantes, FMP s'engage à fournir des solutions de haute qualité, conçues avec précision et dans les délais impartis, garantissant ainsi à ses clients un service et des résultats optimaux.

Au cœur des activités de FMP se trouve notre souci constant de la qualité. Nous adhérons aux normes de fabrication les plus strictes et appliquons des mesures de contrôle qualité rigoureuses pour garantir que chaque produit réponde aux attentes de l'industrie, voire les dépasse. Cet engagement envers la qualité, associé à nos valeurs fondamentales d'intégrité, de travail d'équipe et de persévérance, nous a permis de bâtir des relations de confiance durables avec nos clients dans près de 30 pays à travers le monde.

FMP est toujours désireux de nouer des partenariats internationaux et s'engage à fournir des conseils d'experts et des solutions sur mesure pour répondre aux divers besoins de ses clients. Notre approche va au-delà de la simple livraison de produits ; nous visons à entretenir des relations durables qui contribuent à la réussite de chaque projet. Que vous ayez besoin de solutions innovantes pour une nouvelle entreprise ou d'un support continu pour un système existant, FMP est là pour relever vos défis techniques et vous accompagner dans la réussite de votre projet.

Auteur : CX