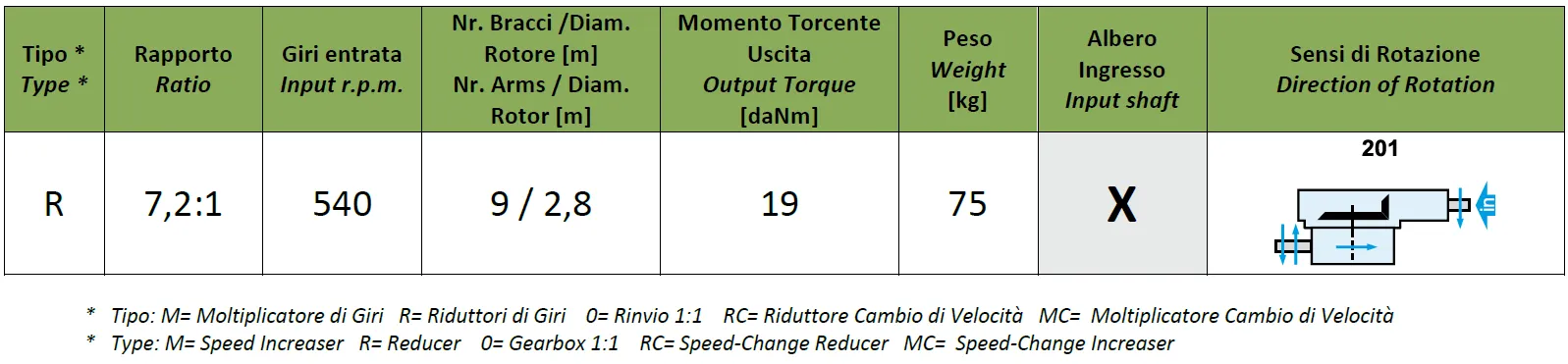

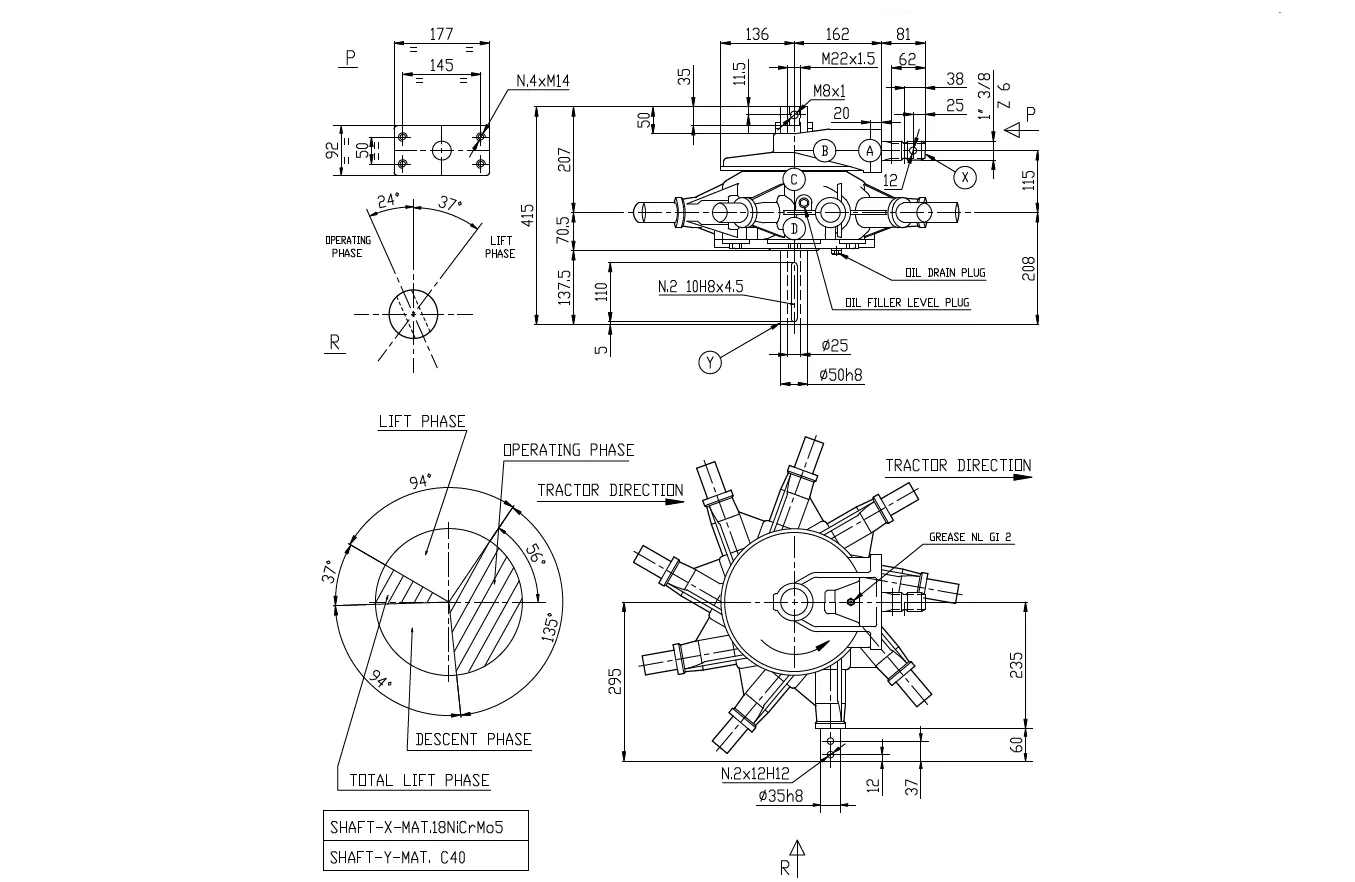

Specifications of Rotary Rake Gearbox K-791A (7.2:1)

| Product Description |

Rotary Rake Gearbox – Replacement of Comer Gearbox K-791A 7.2:1

|

|---|---|

| Product details |

|

| Model |

K-791A

|

| Max. output torque |

190 nm

|

| Suitable for machine/vehicle brand |

|

| Contains oil |

No

|

| Oil SAE viscosity grade |

90EP

|

| Number of arms |

9

|

| Gear ratio |

7,2:1

|

| Input shaft |

1 3/8 Z6

|

| Shaft type |

1 x 1.3/8 (Z6)

|

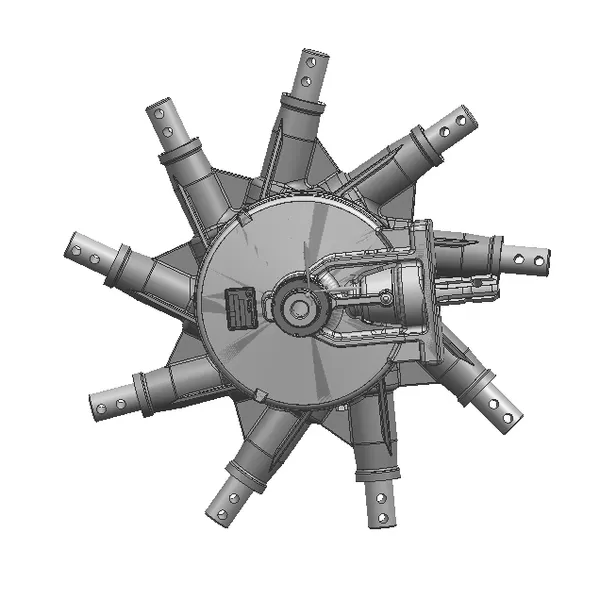

Benefits of Rotary Rake Gearbox

- Mayor eficiencia: Rotary rake gearboxes are designed to optimize the raking process in agricultural machinery, ensuring faster and more efficient operation. They transmit power effectively from the tractor’s PTO (Power Take-Off) system to the rake, resulting in improved productivity during hay and straw raking.

- Durability and Reliability: Built with high-quality materials and precision engineering, rotary rake gearboxes are designed for long-lasting performance under heavy-duty conditions. Their robust construction ensures reliable operation even in tough agricultural environments, reducing downtime and the need for frequent maintenance.

- Control de precisión: These gearboxes offer precise control over the rake’s motion, ensuring uniform and consistent raking of crops. The gearbox’s design allows for smooth operation, enabling the machine to efficiently handle various crop types and conditions.

- Versatility: Rotary rake gearboxes are versatile and can be used with various types of rotary rakes, making them suitable for different agricultural applications such as haymaking, straw management, and silage production. This adaptability provides farmers with a flexible solution for a range of raking tasks.

- Reduced Power Loss: The advanced design of rotary rake gearboxes ensures minimal power loss between the tractor and the rake. This means more of the engine’s power is transferred to the rake, improving overall fuel efficiency and reducing operating costs.

In summary, rotary rake gearboxes provide significant benefits in terms of operational efficiency, reliability, ease of maintenance, and long-term cost-effectiveness. These advantages make them an essential component of modern agricultural machinery, particularly for tasks related to haymaking, crop management, and silage production.

|

|

Applications of Rotary Rake Gearboxes

- Haymaking and Forage Raking: Rotary rake gearboxes are primarily used in haymaking and forage raking. They enable the efficient gathering and turning of hay, allowing farmers to create uniform windrows for drying. The gearbox ensures smooth and precise power transmission to the rake, enhancing the efficiency of the raking process and reducing the time required for hay drying.

- Straw Raking: In addition to hay, rotary rake gearboxes are used in straw raking, where they facilitate the even distribution and gathering of straw after harvesting. By creating well-formed windrows, the gearbox ensures that straw is collected efficiently, either for use in bedding or for further processing.

- Silage Raking: Rotary rake gearboxes are also crucial in silage preparation. They help in gathering and turning crops such as grass, maize, or clover, which are then fermented for use as animal feed. The precision and efficiency offered by the gearbox ensure that the silage is evenly spread, contributing to better fermentation and storage.

- Tedding: In some cases, rotary rake gearboxes are used in tedding operations, which involve spreading freshly mown grass or hay. By helping to evenly distribute the crop across the field, rotary rake gearboxes enable faster drying times, reducing the risk of spoilage and enhancing the quality of the final product.

- Crop Re-handling: After crops have been harvested, rotary rake gearboxes are used in re-handling operations where crops are redistributed or reshaped for further processing. This is especially important in large-scale farming operations where high volumes of crops need to be moved or processed efficiently.

In summary, rotary rake gearboxes are used in a variety of applications across farming and agriculture. Their versatility makes them essential in haymaking, straw raking, silage preparation, and multi-functional farming machinery. They enable efficient crop management, improve product quality, and help streamline operations in both large-scale and smaller, specialized agricultural settings.

PTO Shaft and Rotary Rake Gearbox

A PTO (Power Take-Off) shaft and a rotary rake gearbox are both crucial components in modern agricultural machinery, specifically in tasks such as haymaking, forage raking, and crop management. Here’s how they work together:

1. Function of the PTO Shaft

A PTO shaft is a mechanical device that transmits power from a tractor’s engine to various attached implements or machinery. It connects the tractor’s engine to external equipment, allowing it to function without needing its own power source. The PTO shaft allows the tractor to power implements such as rotary rakes, mowers, balers, and other agricultural machinery. Key features of a PTO shaft:

- Power Transmission: It transfers rotational power from the tractor’s engine to the equipment.

- Adjustability: PTO shafts come in different sizes and lengths to fit various types of machinery, ensuring compatibility across different models.

- Safety: Proper guarding and safety mechanisms are essential to prevent injuries caused by moving parts.

2. Role of the Rotary Rake Gearbox

The rotary rake gearbox is responsible for converting the rotational power from the PTO shaft into mechanical movement for the rake’s tines or arms. The gearbox takes the incoming power and controls the rotation speed and torque needed to efficiently perform the raking operation. Key features of a rotary rake gearbox:

- Power Conversion: It converts the rotational power supplied by the PTO shaft to drive the rotary rake mechanism.

- Speed Control: The gearbox ensures the correct speed for the rake, optimizing the hay raking or forage spreading process.

- Torque Amplification: The gearbox may provide torque amplification to ensure the rake has enough power to handle heavy loads, such as dense hay or crops.

3. How PTO Shaft and Rotary Rake Gearbox Work Together

When attached to the tractor, the PTO shaft provides the mechanical power needed to drive the rotary rake gearbox. The PTO shaft is connected to the tractor’s PTO output and transfers rotational motion via a universal joint or coupling to the rotary rake gearbox. The gearbox, in turn, ensures that this power is effectively harnessed and distributed to the rake’s rotating arms or tines.

- Power Transfer: The PTO shaft transmits rotational energy from the tractor’s engine to the gearbox, ensuring the rake operates efficiently.

- Speed and Torque Regulation: The gearbox adjusts the power to the rake mechanism, controlling its speed and the torque required to handle various tasks like hay raking or crop spreading.

- Operational Efficiency: By combining the PTO shaft with the rotary rake gearbox, the tractor can power a wide range of rakes with varying load capacities, all with precision and reliability.

4. Benefits of PTO Shaft and Rotary Rake Gearbox Combination

- Efficient Power Transmission: The PTO shaft ensures reliable power delivery from the tractor to the rake, enabling smooth operation across a variety of field conditions.

- Versatility: This combination is widely used in different agricultural applications, from small-scale farms to large, commercial operations. The PTO shaft allows for easy interchangeability between different implements, while the gearbox optimizes the rake’s functionality.

- Ease of Use: The PTO shaft and rotary rake gearbox work together seamlessly to minimize the need for manual intervention and provide optimal performance with minimal setup time.

- Cost-Effective: By using a PTO shaft and rotary rake gearbox combination, farmers can reduce the need for additional power sources or complex machinery, making it a more economical choice for raking and crop management tasks.

5. Maintenance and Safety Considerations

- Routine Maintenance: Regular maintenance of the PTO shaft, including lubrication and checking for wear, ensures longevity and reliability. Similarly, the gearbox should be inspected for signs of damage or malfunction to maintain smooth operation.

- Safety Precautions: As with all PTO-driven equipment, safety shields or guards should be used to prevent accidents. The PTO shaft should be properly maintained and operated within the recommended limits to avoid damage to both the tractor and attached equipment.

The PTO shaft and rotary rake gearbox are essential components of modern agricultural machinery, working in tandem to provide efficient, reliable, and safe power transmission for raking and other related tasks. Together, they offer versatility, operational efficiency, and ease of use, making them indispensable in the field of agriculture.

|

|

Acerca de FMP

Based in Italy, FMP is a leading manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, primarily focusing on the agricultural machinery sector. Renowned for its precision engineering, innovative solutions, and consistent reliability, FMP has built a strong reputation as a trusted partner in both agricultural and industrial markets. Our diverse portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and an extensive range of essential components, all meticulously crafted to address the specific demands of various applications. At FMP, we understand that each client faces unique challenges. That’s why we specialize in providing tailored solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that every solution not only meets their precise needs but also optimizes performance and enhances value. Our commitment to prompt, professional responses and expert guidance ensures that every inquiry is addressed with accuracy, consistently delivering the best possible outcomes. Effective and continuous communication is a cornerstone of our approach throughout the entire product development process. Our dedicated team collaborates directly with clients to gain a thorough understanding of their needs, offering valuable insights and recommendations to ensure optimal results. Whether designing cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to consistently exceed client expectations by providing exceptional service and delivering outstanding results with every project. Quality is at the heart of everything we do at FMP. We adhere to the highest manufacturing standards and implement stringent quality control measures to ensure that each product not only meets but often exceeds industry benchmarks. This commitment to excellence, coupled with our core values of integrity, teamwork, and perseverance, has helped us build long-lasting, trust-based relationships with clients in nearly 30 countries around the world. FMP is always eager to cultivate global partnerships, offering expert advice and customized solutions to meet the evolving needs of our clients. We are dedicated to building long-term, mutually beneficial relationships that contribute to the success of every project. Whether you are looking for innovative solutions for a new initiative or require ongoing support for an existing system, FMP is here to help you overcome technical challenges and ensure your continued success.  Autor: CX

Autor: CX