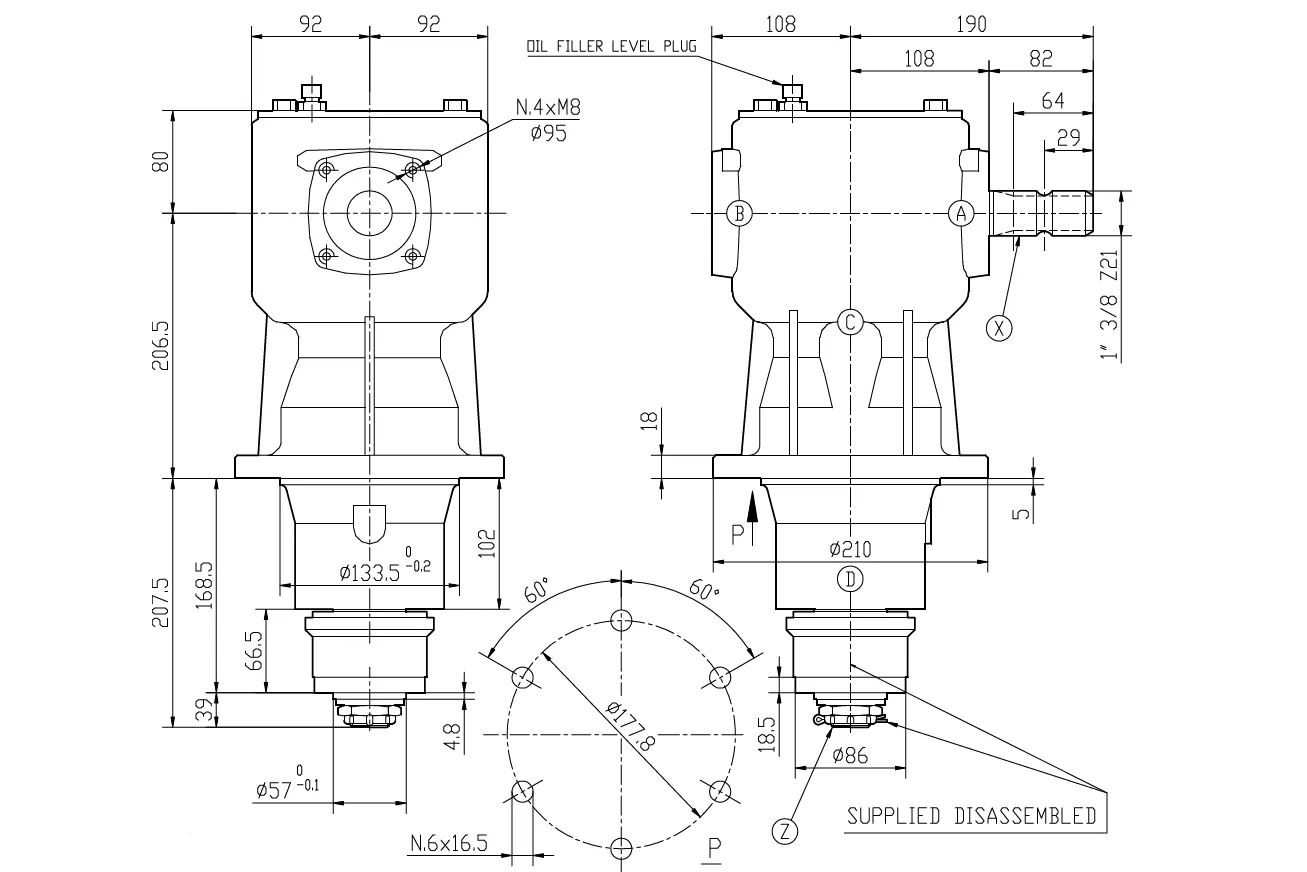

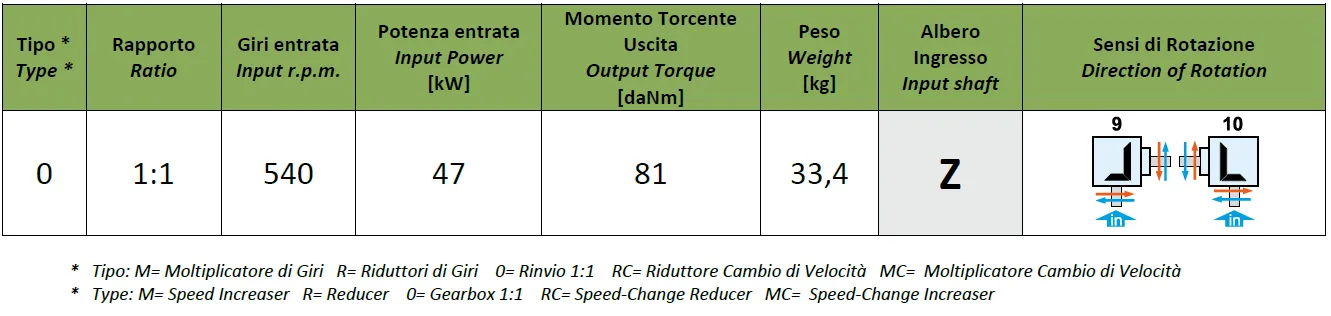

Specifications of Rotary Mower Gearbox LF-149B (1:1)

| Product Description |

Rotary Mower Gearboxes – Replacement of Comer Gearbox LF-149B 1:1

|

|---|---|

| Product details |

|

| Max. input power |

47 kW

|

| Contains oil |

No

|

| Max. oil capacity |

0.8 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

| Weight |

33.4 kg

|

| Gear arrangement Increasing |

3

|

| Gear ratio |

1:1

|

| Input power kW / HP Increasing |

47 / 55 kW/HP

|

| Input shaft Increasing |

Z

|

| Output Torque DaNm Increasing |

81 daNm

|

| Ratio Increasing |

1: 1

|

| Ratio Reducing |

1: 1

|

| Shaft Z |

1 3/8″ (21)

|

Agricultural PTO Shaft and Rotary Mower Gearbox

An agricultural PTO (Power Take-Off) shaft is an essential mechanical component used to transfer power from a tractor’s engine to various attached implements, such as rotary mower gearboxes. The PTO shaft connects directly to the tractor’s engine output, transferring both power and torque to the equipment it’s connected to. This allows for efficient operation of heavy-duty machinery, such as mowers, tillers, and other agricultural tools.

The rotary mower gearbox plays a critical role in the mowing process by converting the high-speed rotation of the PTO shaft into the slower, high-torque rotation required to operate the mower blades. This transformation ensures that the mower blades can generate enough force to cut through dense grass and vegetation efficiently. By increasing torque and reducing the speed, the gearbox optimizes the power transmitted from the engine, ensuring a smooth and effective mowing operation.

The combination of an agricultural PTO shaft and a rotary mower gearbox is a widely adopted method for maintaining large areas of land, such as farms, pastures, and fields. This system provides a powerful and efficient solution for mowing large expanses of land, helping farmers, landscapers, and landowners manage their properties with ease.

How It Works:

To operate the PTO shaft and rotary mower gearbox system, the PTO shaft is first connected to the tractor’s PTO output. The other end of the shaft is attached to the input of the rotary mower gearbox. Once engaged, the PTO shaft delivers rotational power to the gearbox. The gearbox then steps up the torque while slowing down the rotational speed, which drives the mower blades to rotate at the optimal speed for cutting. The rapidly spinning blades slice through the grass, and the entire system continues to work across the field, ensuring a clean and efficient cut.

Key Benefits:

- Efficient Land Maintenance: This system allows for the fast and efficient mowing of large fields, making it an essential tool for agricultural maintenance.

- Powerful Performance: The combination of PTO power and the torque-enhancing gearbox ensures that even tough, thick grass can be cut through with ease, providing consistent performance in various conditions.

- Durability and Reliability: Both the PTO shaft and rotary mower gearbox are built to withstand the demanding environments of farming, ensuring long-term durability and reliable performance.

- Time-Saving: Using a PTO shaft and rotary mower gearbox allows for faster mowing compared to traditional methods, reducing the amount of time spent on land maintenance.

Overall, the agricultural PTO shaft and rotary mower gearbox are indispensable tools for efficient and effective land management. They provide the necessary power to handle large-scale mowing tasks, ensuring that farmers and landowners can keep their properties in top condition with minimal effort and time. This robust system significantly enhances productivity, reduces operational costs, and allows for regular land maintenance, especially in areas with dense vegetation.

|

|

Acerca de FMP

FMP, based in Italy, is a renowned company specializing in the research, development, and manufacturing of gearboxes, reducers, and engineering machinery. Established as an industry leader, FMP has built its reputation by focusing on innovation, quality, and a strong commitment to fostering talent, positioning itself as a key player in the mechanical engineering sector.

Comprehensive Product Portfolio

FMP offers a wide range of high-performance products designed to meet diverse industry needs. Their portfolio includes spiral bevel gearboxes, spur gearboxes, worm gearboxes, cylindrical gearboxes, and high-pressure cast valve bodies and housings. Each product is crafted with precision to deliver reliable, efficient performance across a variety of applications.

Wide Applications Across Industries

FMP’s products are versatile and serve a broad spectrum of industries, including agriculture, where they power equipment such as rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. Additionally, FMP supplies industrial machinery for oil extraction, marine applications, and hydraulic components, demonstrating the adaptability and reach of their product offerings.

Advanced Manufacturing Excellence

FMP’s manufacturing process is a testament to its commitment to quality and precision. From product design to material selection, the company ensures every step is tailored to meet specific client needs. High-grade materials such as cast iron and aluminum alloys are selected for durability, while advanced machining techniques, including turning and milling, ensure the accuracy of each component. The assembly process is meticulous, with a focus on alignment and lubrication, while heat and surface treatments improve strength, wear resistance, and appearance. Rigorous quality control measures ensure each product meets performance standards for stability and reliability.

Industry Reputation and Global Partnerships

FMP’s dedication to quality, innovation, and customer satisfaction has earned it a stellar reputation within the manufacturing industry. The company continues to build on its legacy by leveraging advanced technology and craftsmanship. FMP welcomes global partnerships and collaborations, committed to providing tailored solutions that meet the unique needs of clients worldwide. For more information on products and services, potential partners can easily reach out via phone or email, reinforcing FMP’s commitment to customer-driven excellence.

Author: CX