Rotary Cutter Gearboxes – Replacement of Omni Code RC-100 Gearbox

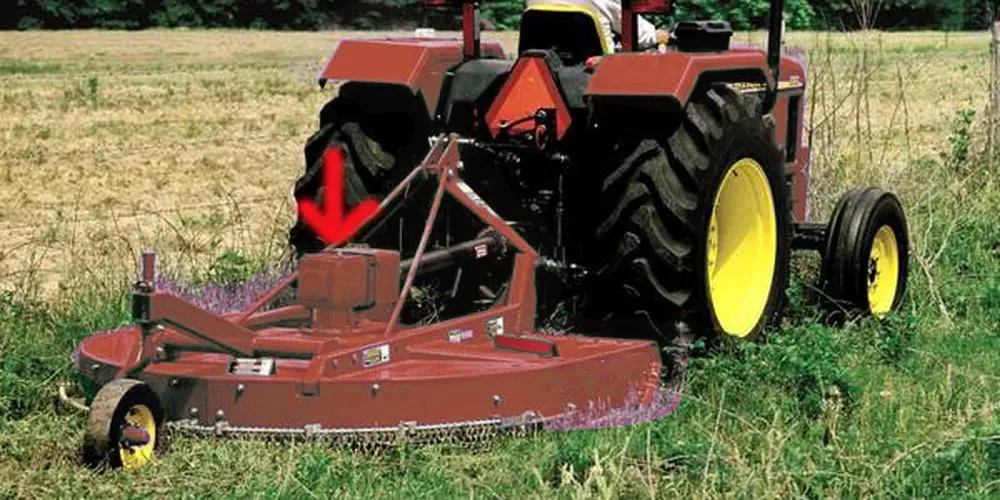

The Rotary Cutter Gearbox – Replacement of Omni Code RC-100 Gearbox is a high-performance, durable solution specifically designed to replace the Omni Code RC-100 gearbox in rotary cutter systems. Engineered to handle demanding agricultural and industrial applications, this replacement gearbox ensures reliable power transmission, optimal cutting performance, and long service life for rotary cutters used in a variety of vegetation management tasks, including mowing, land clearing, and brush cutting.

Características principales:

- High Power Capacity

The RC-100 replacement gearbox is built to support up to 100 horsepower, making it ideal for heavy-duty applications such as land clearing, brush cutting, and large-scale mowing. Its robust design ensures efficient power transfer to the cutting blades, delivering reliable performance even under the most challenging conditions. - Durable and Long-Lasting Construction

Constructed with high-strength materials, the replacement gearbox is designed to withstand the wear and tear of continuous use in demanding environments. Its corrosion-resistant housing, high-quality seals, and rugged internals ensure that the gearbox can handle exposure to dirt, moisture, and debris while maintaining long-lasting reliability and durability. - Efficient Power Transmission

This gearbox features a precision-engineered internal gear system that efficiently transmits power from the PTO shaft to the rotary cutter blades. The efficient power transfer minimizes energy loss, ensuring smooth blade rotation and optimal cutting performance. This efficiency helps reduce fuel consumption and operational costs, making it a cost-effective solution for operators.

The Rotary Cutter Gearbox – Replacement of Omni Code RC-100 Gearbox offers a high-quality, durable, and efficient solution for rotary cutter systems. Built to handle heavy-duty tasks with ease, it provides reliable power transmission, reduced fuel consumption, and minimal maintenance. Its seamless compatibility with existing systems ensures a quick, hassle-free installation, making it an excellent choice for agricultural, industrial, and land management applications. With its robust construction and focus on performance, this replacement gearbox delivers long-lasting reliability and value for rotary cutter operations.

Specifications of RC100 Rotary Cutter Gearbox

| Model: | FMP-RC100 Rotary Cutter Gearbox |

| Horsepower: | 50-150 HP |

| Input Shaft: | 1 3/8 in 6 A Spline |

| Output Shaft: | 15 Spline |

| Ratio: | 1:1.46 |

| Rotation: | Reverse |

| Applications | Finishing Mowers Rotary Cutters Rotary Slashers |

Features of RC100 Rotary Cutter Gearbox

The RC100 Rotary Cutter Gearbox is engineered for high-performance, durability, and efficiency, making it an ideal choice for demanding agricultural and industrial applications. This gearbox is designed to provide reliable power transmission and optimal cutting performance in a wide range of rotary cutter systems. Below are the key features of the RC100 Rotary Cutter Gearbox:

High Power Capacity

The RC100 gearbox is designed to handle up to 100 horsepower, ensuring it can power rotary cutter blades through tough vegetation, thick grass, and dense brush. With its high power capacity, the gearbox is suitable for heavy-duty tasks such as land clearing, large-scale mowing, and vegetation management, making it a reliable choice for both agricultural and industrial applications.

Durable and Robust Construction

Built with premium materials and advanced manufacturing techniques, the RC100 gearbox features a rugged, durable design that ensures long-lasting performance. The gearbox housing is made from high-strength materials that can withstand harsh environmental conditions, including exposure to dirt, moisture, and debris. This robust construction helps to reduce wear and tear, ensuring the gearbox remains reliable under heavy operational loads.

Efficient Power Transmission

The RC100 gearbox is equipped with an optimized gear system that minimizes energy loss during power transfer from the PTO shaft to the cutting blades. This efficient power transmission ensures that the rotary cutter blades maintain consistent speed and cutting performance, improving fuel efficiency and reducing operational costs. The gearbox is engineered to provide smooth, reliable operation with minimal maintenance required.

Seamless Integration and Compatibility

Designed as a direct replacement for the Omni Code RC-100 gearbox, the RC100 gearbox offers seamless integration into existing rotary cutter systems. Its precise fit ensures easy installation with minimal adjustments needed, reducing downtime during replacement. The gearbox is fully compatible with a variety of rotary cutters, making it a versatile and cost-effective solution for operators seeking a reliable replacement.

Low Maintenance and Longevity

The RC100 rotary cutter gearbox is designed to require minimal maintenance over its lifespan. With features like high-quality bearings, seals, and an efficient lubrication system, the gearbox ensures smooth operation and extends service life. Regular checks on lubrication levels are typically the only maintenance required, minimizing downtime and reducing the need for costly repairs or replacements. This low-maintenance design ensures that the gearbox provides long-lasting reliability and performance in tough cutting conditions.

The RC100 Rotary Cutter Gearbox is a high-performance, durable, and efficient solution for heavy-duty rotary cutter applications. With its high power capacity, rugged construction, efficient power transmission, and low-maintenance design, this gearbox ensures reliable and long-lasting performance, making it an excellent choice for demanding agricultural and industrial tasks.

Applications of RC100 Rotary Cutter Gearbox

The RC100 Rotary Cutter Gearbox is engineered for demanding agricultural and industrial applications that require reliable power transmission and high-performance cutting capabilities. Designed to handle tough vegetation and rough environments, this gearbox excels in a variety of operational settings. Below are some of the key applications where the RC100 Rotary Cutter Gearbox is commonly used:

Agricultural Field Maintenance

The RC100 gearbox is ideal for use in agricultural operations, particularly for maintaining large fields and pastures. It provides the necessary power and torque to rotary cutters, enabling efficient mowing of grass, weeds, and other vegetation. Farmers and agricultural contractors use this gearbox for tasks such as grass cutting, hayfield management, and land clearing, ensuring high-quality results with minimal downtime.

Land Clearing and Brush Cutting

In land clearing and brush cutting applications, the RC100 gearbox delivers the high horsepower needed to cut through dense brush, small trees, and heavy vegetation. Whether used for clearing construction sites, utility corridors, or forestry management, the gearbox ensures the rotary cutter blades maintain consistent performance under demanding conditions. Its robust design makes it an excellent choice for land developers, forestry contractors, and municipalities.

Roadside and Municipal Maintenance

Local governments and contractors rely on the RC100 rotary cutter gearbox for maintaining roadsides, highways, and public spaces. The gearbox powers rotary cutters that trim grass, clear weeds, and manage vegetation along roads, fences, and parks. Its ability to handle tough cutting conditions makes it a valuable tool for municipal maintenance, ensuring that public spaces remain neat, safe, and well-maintained throughout the year.

Golf Course and Recreational Area Maintenance

Golf courses, sports fields, and recreational areas require precision cutting to maintain their aesthetic appearance. The RC100 gearbox is used in rotary cutters designed for fine turf management, ensuring smooth, even cuts on large areas of grass. With its power and efficiency, the gearbox is also used in more rugged areas, such as managing rough grass and vegetation around golf courses, parks, and outdoor recreational spaces.

Industrial and Heavy-Duty Mowing Applications

In industrial settings, the RC100 gearbox is utilized for heavy-duty mowing applications that demand consistent and reliable performance. This includes vegetation management on large industrial estates, power plants, and other large-scale facilities. The gearbox’s high power output ensures that rotary cutters can tackle thick grass, shrubs, and other unwanted vegetation, keeping industrial sites clean and safe while improving operational efficiency.

The RC100 Rotary Cutter Gearbox is a versatile and reliable solution for a wide range of agricultural, industrial, and municipal applications. Whether used for field maintenance, land clearing, roadside mowing, or recreational area upkeep, the gearbox provides the power and durability required to handle tough cutting tasks efficiently. Its robust design and high-performance capabilities make it an indispensable tool for anyone in need of reliable, heavy-duty rotary cutting power.

Rotary Cutter Gearboxes and PTO Shafts

Rotary Cutter Gearboxes and PTO shafts are vital components in agricultural and industrial rotary cutter systems, working together to ensure efficient power transmission and effective cutting performance. These systems are commonly used in tasks such as mowing, brush clearing, and vegetation management, where reliability, durability, and performance are essential. Below is an overview of how these components function together and their significance in rotary cutter applications.

Role of Rotary Cutter Gearboxes

A rotary cutter gearbox serves as the central mechanism that transfers power from the tractor’s Power Take-Off (PTO) system to the rotary cutter blades. The gearbox reduces the rotational speed from the PTO shaft, converting it into the correct speed and torque to drive the blades effectively. This reduction allows the blades to cut through dense vegetation, such as grass, shrubs, and small trees, with optimal efficiency. Gearboxes are designed to withstand heavy loads, ensuring reliable performance in challenging working conditions.

Power Transmission with PTO Shafts

The PTO shaft connects the tractor’s PTO system to the rotary cutter gearbox. It serves as the link for transmitting mechanical power from the tractor’s engine to the gearbox, which then drives the rotary cutter blades. PTO shafts are designed to handle high torque, transferring power with minimal energy loss. These shafts typically feature a universal joint at both ends, allowing for smooth, flexible connection and operation between the tractor and the rotary cutter, ensuring that power is efficiently delivered to the gearbox.

Compatibility and Integration

Both rotary cutter gearboxes and PTO shafts are designed to integrate seamlessly into rotary cutter systems. The gearbox is engineered to fit various cutter designs, while PTO shafts come in different lengths and configurations to accommodate various tractor models. This compatibility ensures that the power transfer between the PTO shaft and the gearbox is efficient, reducing the risk of mechanical failure and ensuring smooth operation of the cutting blades. Whether for large-scale mowing or land clearing, the ease of integration between these components is key to achieving optimal performance.

Durability and Maintenance

Both components are built for durability, designed to withstand harsh conditions such as exposure to debris, moisture, and constant stress from high rotational speeds. Rotary cutter gearboxes feature robust, heavy-duty construction to handle the shock loads from cutting through tough vegetation. Similarly, PTO shafts are designed to be resilient, with safety shields and reinforced components to protect against damage during operation. Regular maintenance, including lubrication and inspections, is essential to ensure the longevity and reliability of both the gearbox and the PTO shaft.

Safety Considerations

Safety is a key consideration when operating rotary cutter systems, as both the PTO shaft and rotary cutter gearbox involve high-speed rotating parts. PTO shafts are often equipped with safety shields and shear pins to prevent accidental contact or damage. The gearbox is housed in a sturdy casing to protect internal components and prevent contamination from dirt and debris. Operators should always ensure that these safety features are in place and perform regular inspections to maintain safe, efficient operation.

The combination of rotary cutter gearboxes and PTO shafts is essential for efficient rotary cutting systems, ensuring that power is transmitted effectively from the tractor to the cutting blades. The gearbox reduces rotational speed and increases torque to drive the blades, while the PTO shaft provides the necessary power transfer from the tractor’s PTO system. These components are engineered for durability and reliability, ensuring smooth operation and safety in various agricultural and industrial applications. Regular maintenance and proper safety protocols help extend the life of these vital components, making them indispensable tools for vegetation management, land clearing, and other heavy-duty cutting tasks.

|

|

Acerca de FMP

Headquartered in Italy, FMP is a leading manufacturer with a strong reputation for excellence in the design, development, and production of high-performance gearboxes, specializing in the agricultural machinery sector. Renowned for our precision engineering, innovative solutions, and unmatched reliability, FMP consistently delivers top-tier products that meet the evolving demands of both the agricultural and industrial markets. Our extensive product range includes advanced gearboxes for lawn mowers, PTO shafts, and other key components, all designed to provide tailored solutions for a wide variety of applications.

At FMP, we understand that each client has unique challenges and requirements. That’s why we offer customized solutions, whether it’s individual components or fully integrated systems. We collaborate closely with our customers to ensure that every solution not only addresses their specific needs but also enhances performance and maximizes value. Our commitment to fast, professional responses, paired with expert guidance, ensures that every inquiry is managed with precision and care.

We place great emphasis on clear, ongoing communication, particularly when developing new products. Our dedicated team works directly with clients to understand their specific needs, providing practical insights that lead to optimal, effective solutions. Whether we’re developing cutting-edge products or fulfilling ongoing orders, we remain committed to delivering high-quality, precision-engineered solutions that meet the highest standards of speed and reliability.

Quality is at the core of FMP’s operations. We adhere to stringent manufacturing standards and implement rigorous quality control procedures to ensure every product not only meets but exceeds industry expectations. Our unwavering commitment to quality, combined with our values of integrity, collaboration, and persistence, has enabled us to build long-term partnerships with clients across more than 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to providing expert advice and customized solutions that address the diverse needs of our clients. We go beyond simply supplying products—we strive to establish meaningful, long-lasting relationships that contribute to the success of every project. Whether you’re looking for innovative solutions for a new initiative or ongoing support for an existing system, FMP is committed to helping you overcome technical challenges and ensuring your continued success.

Autor: CX