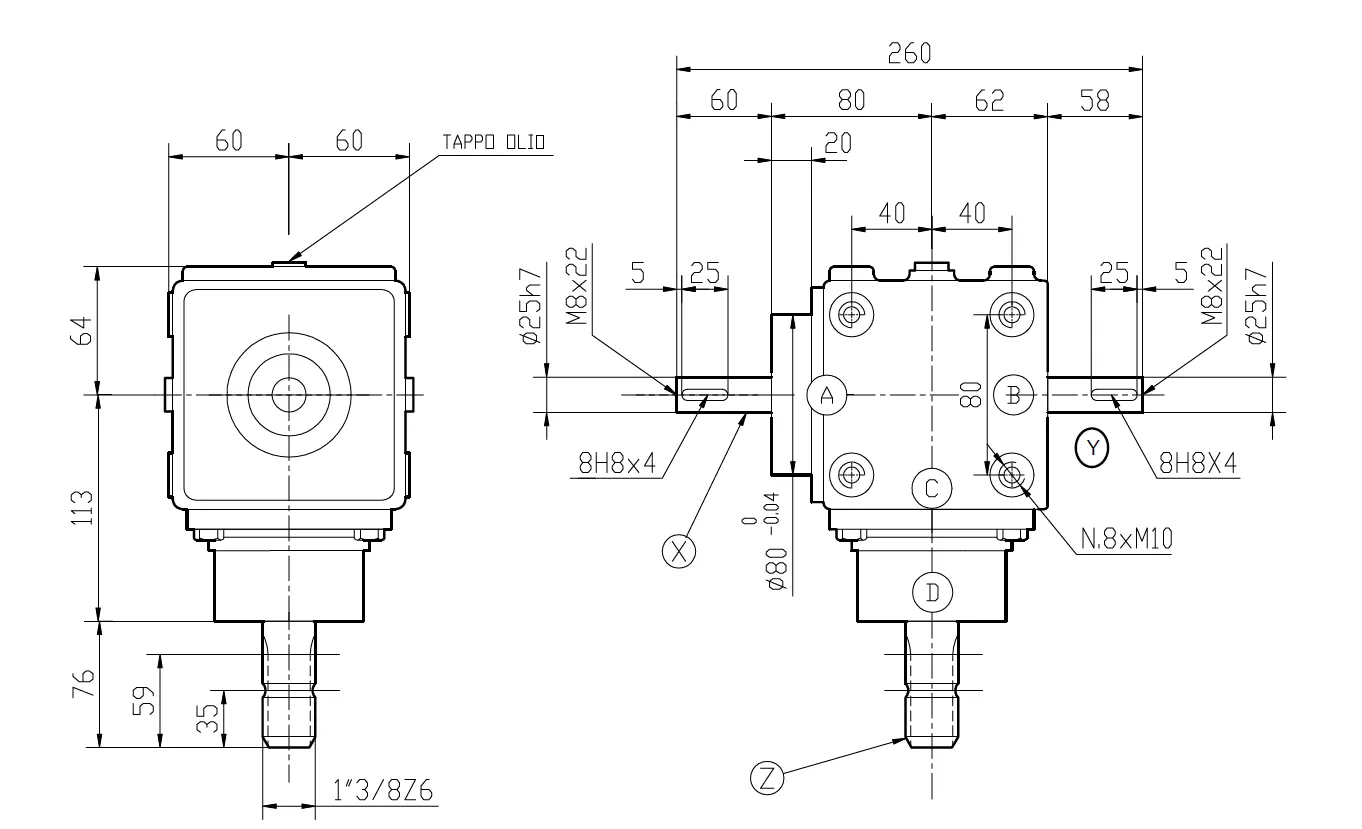

Specifications of Flail Mower Gearboxes TL281E

| i | 2.91/1.85 |

| N1[rpm] | 540 |

| P1[kW] | 8.1-14.7 |

| METRO2[Nm] | 48-136 |

Shaft X |

1” 3/8 Z6 |

Shaft Z |

Φ25/Φ30 |

| Input | X |

Characteristics of Flail Mower Gearbox

The flail mower gearbox is a critical component that plays a vital role in converting the tractor’s PTO (Power Take-Off) power into usable energy for the mower blades. Its design ensures that the mower can operate efficiently in various agricultural, forestry, and landscaping tasks, handling different types of vegetation. Here are the key characteristics of a flail mower gearbox:

Power Transmission and Torque Conversion

One of the most important characteristics of the flail mower gearbox is its ability to convert high-speed PTO power into the correct torque and rotational speed for the mower blades. The gearbox reduces the RPM from the tractor’s PTO, typically 540 or 1000 RPM, to a lower, more appropriate speed for efficient cutting. This conversion ensures that the mower blades rotate at the correct speed to cut through dense grass, brush, or thick vegetation without overloading the system.

Durability and Strength

Flail mower gearboxes are built to withstand heavy loads and harsh conditions. These gearboxes are made from high-quality, durable materials such as hardened steel or cast iron, which can handle the extreme forces and high torque demands associated with heavy-duty agricultural applications. The internal gears and bearings are designed to endure shock loads, wear, and vibrations, ensuring long-lasting performance even in demanding environments.

High Efficiency

Flail mower gearboxes are designed for high-efficiency power transmission. The gears are typically helical or bevel-shaped, which reduces friction and energy loss, leading to smoother operation and greater fuel efficiency. Efficient power transmission means that less energy is wasted in the conversion process, ensuring that more of the tractor’s engine power is used to drive the mower blades. This leads to better overall performance and reduces fuel consumption during operation.

Multiple Output Shafts (for Different Cutting Angles)

Many flail mower gearboxes come equipped with multiple output shafts that allow the mower blades to be driven at different cutting angles. This is particularly useful for adjusting cutting heights or handling different types of vegetation. Some gearboxes feature a bevel gear system that can change the direction of power transmission, enabling the mower to work in a variety of configurations. These multi-output shafts ensure that the mower is adaptable to different tasks and terrains.

Safety Features

Safety is a critical consideration in the design of flail mower gearboxes. Shear bolts, torque limiters, or overload clutches are commonly used to prevent damage to the gearbox, PTO shaft, or mower blades in the event of a sudden obstruction, such as a large rock or dense debris. These safety features ensure that if the mower encounters an obstacle, the gearbox will disengage or absorb the shock to protect the equipment and prevent costly damage.

The flail mower gearbox is designed to provide efficient power transmission, durability, and adaptability for a range of agricultural and landscaping applications. With key characteristics such as torque conversion, high efficiency, safety features, and easy maintenance, the gearbox ensures that the flail mower operates at peak performance while maintaining the longevity of the machinery. Whether dealing with dense vegetation, tough terrain, or demanding work conditions, the flail mower gearbox is engineered to meet the challenges, offering operators a reliable solution for mowing and clearing tasks.

PTO Shafts for Flail Mower Gearbox

PTO (Power Take-Off) shafts are crucial components that connect a tractor’s power system to the flail mower gearbox, transferring mechanical energy to operate the mower blades. The PTO shaft is the link between the tractor’s engine and the gearbox, ensuring that the mower receives consistent and reliable power to perform efficiently. Here are the key aspects of PTO shafts for flail mower gearboxes:

Power Transmission

PTO shafts are responsible for transmitting the rotational power from the tractor’s PTO to the flail mower gearbox. Typically designed with universal joints at both ends, these shafts allow for smooth power transmission even when the PTO shaft is not perfectly aligned with the gearbox. The PTO shaft connects directly to the input of the flail mower gearbox, ensuring that the gearbox receives the correct power to turn the blades effectively.

Torque and Speed Adjustment

The PTO shaft for a flail mower gearbox must be capable of handling the specific torque and rotational speed required by the gearbox. The gearbox input shaft receives the PTO shaft’s rotational power, reducing the tractor’s high RPM (usually 540 or 1000 RPM) to a lower, more appropriate speed for the mower blades. This ensures that the mower blades operate at an efficient cutting speed without overloading the tractor’s engine.

Durability and Strength

PTO shafts for flail mower gearboxes are built to withstand heavy-duty conditions and high torque loads. These shafts are made from strong steel or high-grade materials that can handle the stresses associated with continuous use in demanding agricultural and landscaping environments. The shafts are typically heat-treated for extra durability, ensuring that they last longer, even under tough working conditions like cutting dense grass or brush.

Safety Features

For safe operation, many PTO shafts are equipped with safety shields or guards to prevent accidental contact with rotating parts. Overload protection devices such as shear bolts or torque limiters are commonly incorporated into the PTO shaft system. These mechanisms protect both the tractor and the flail mower gearbox from damage in case of an obstruction or excessive load during operation.

Easy Installation and Maintenance

PTO shafts are designed for easy connection and disconnection, typically featuring quick-release mechanisms or telescoping sections that adjust to the necessary length. This flexibility allows for easy adjustment to accommodate different tractor models and mower configurations. Regular maintenance, such as ensuring that the universal joints are lubricated and checking for wear or damage, helps prolong the life of the PTO shaft and maintain smooth operation.

The PTO shaft for a flail mower gearbox plays an integral role in transferring power from the tractor’s PTO system to the gearbox. With features such as durability, safety mechanisms, and flexibility in adjustment, these shafts ensure that the flail mower operates efficiently and safely. Proper maintenance, along with careful selection of the appropriate shaft for the tractor and mower gearbox, helps optimize performance and prolong the life of the equipment. Whether used for regular lawn mowing or more demanding brush-cutting tasks, PTO shafts are essential for ensuring that the flail mower works reliably across a variety of applications.

Acerca de FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Autor: CX