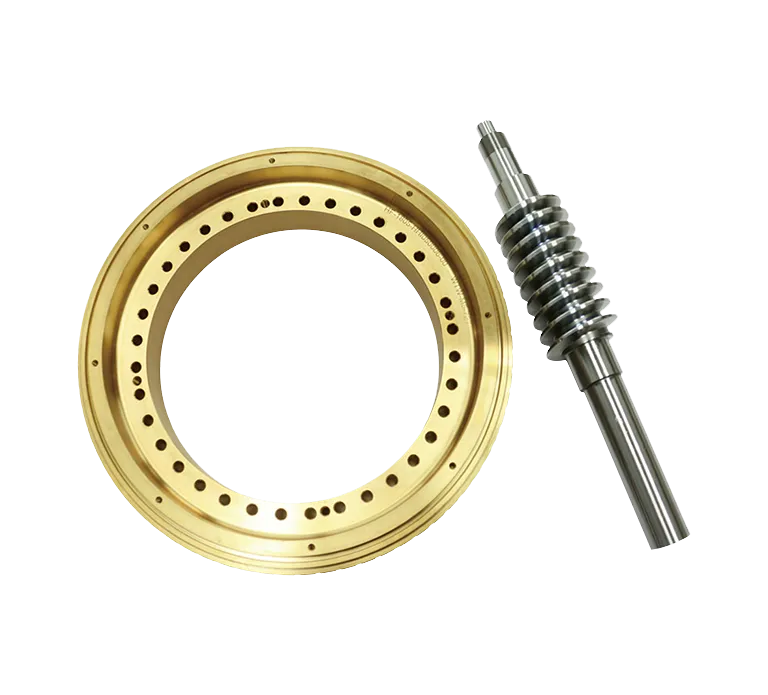

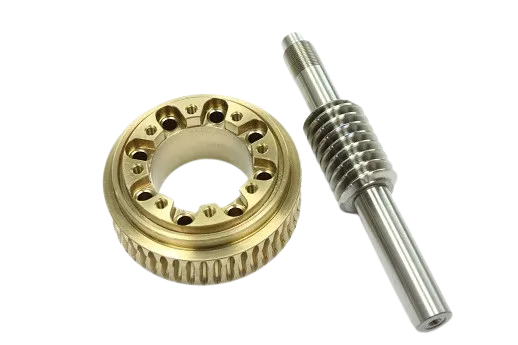

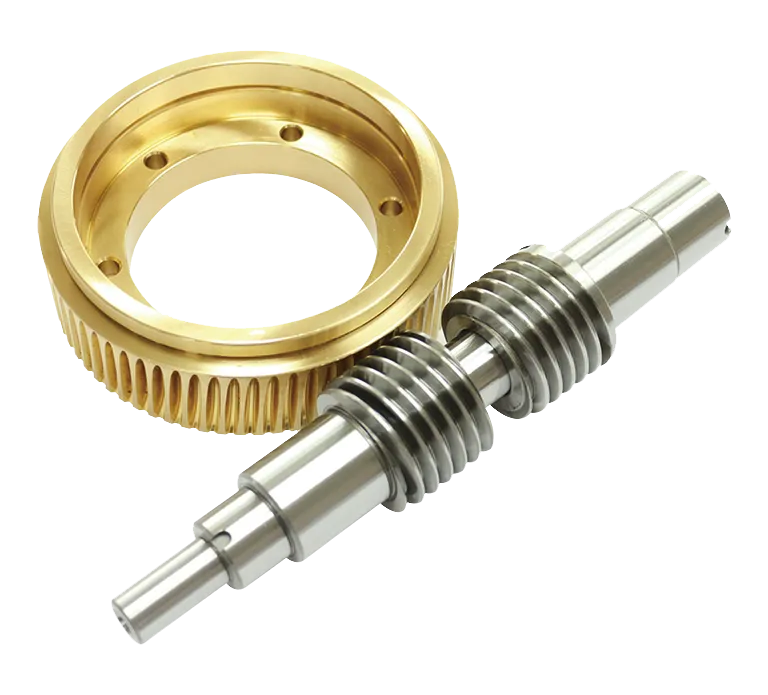

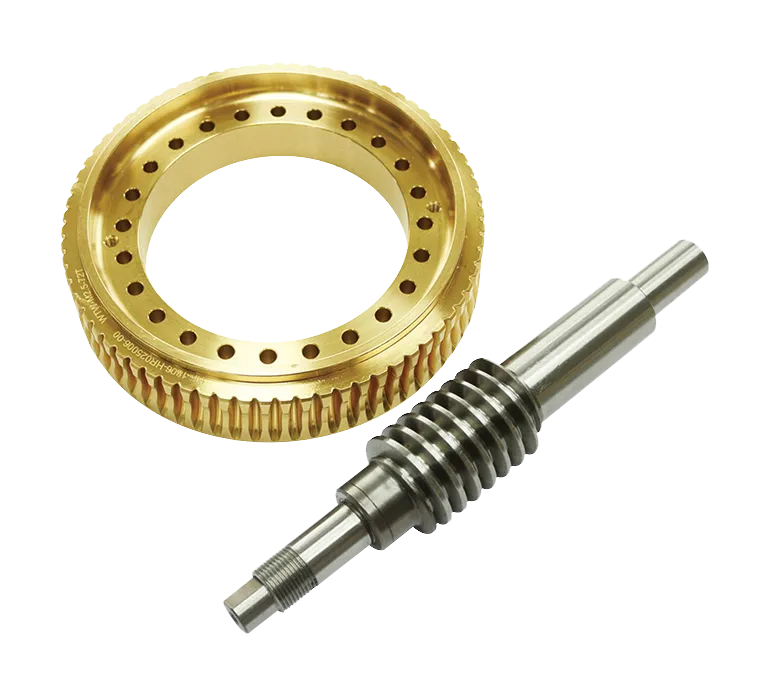

What Are Worm and Wheel Gears?

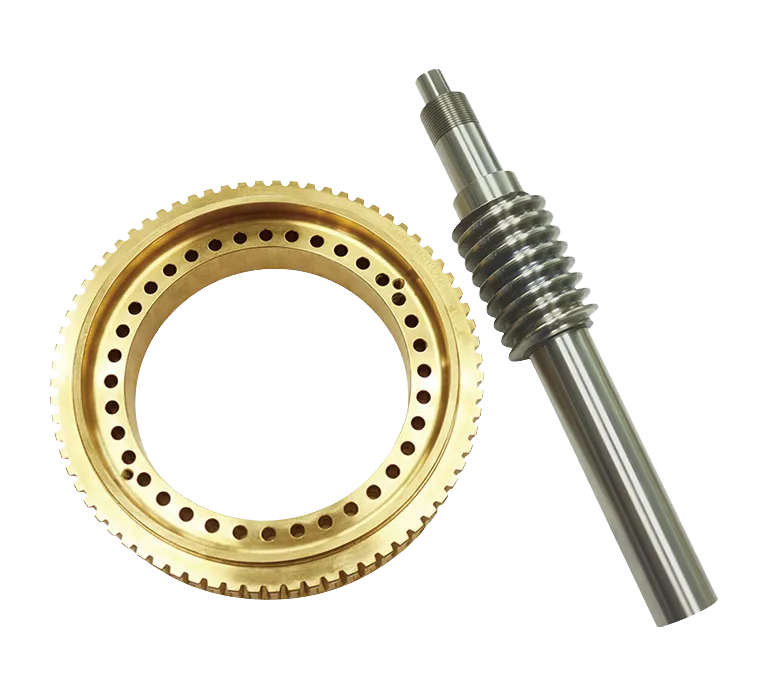

A worm and wheel gear system is a specialized type of gear transmission that transfers motion between two non-intersecting shafts, typically at a 90-degree angle. The system comprises two key components:

- Worm: A cylindrical, screw-like component with spiral threads.

- Worm Wheel: A gear resembling a helical gear, but with concave teeth designed to maximize contact with the worm.

This unique design enables high reduction ratios in a compact form, making worm and wheel gears a go-to solution for applications requiring significant speed reduction and torque increase.

|

|

|

|

|

|

|

|

Especificación

Dimension:Φ5mm- Φ120mm

Module: M0.2-M2.2

Material Type: Aluminum, Bronze, Steel, Alloy, Zinc etc. as customer required

| Precision Worm Gears in Auto Devices | |

| Dimension | Φ5mm- Φ120mm |

| Module | M0.2-M2.2 |

| Material Type | Aluminum, Bronze, Steel, Alloy, Zinc etc. as customer required |

| Meshing Grade | JGMA1/2/3/4/5/6/7/8 ISO 8/7/6/5/4 DIN 6/5/4/3 AGME 12/13/14/15/16 |

| Heat Treatment | ION NITRIDE |

| Solicitud | Automotive, Medical, Industrial, Military, Aircraft, Mechanical etc. |

| Customized | ODM/OEM |

| Sample | Sample available |

| Modes of Packing | Vacuum-packed with Plastic Tray |

| Modes of Delivery | DHL & TNT & FedEx & UPS |

| Certificate | ISO9001:2008 & TS/ISO16949:2008 |

Key Features and Benefits

Worm and wheel gears offer distinct advantages, making them indispensable across various industries:

- High Reduction Ratio: Achieve substantial speed reductions with ease, ideal for high-torque applications.

- Diseño compacto: Among the most space-efficient gear systems, delivering large reductions in minimal space.

- Self-Locking Capability: When the lead angle and friction coefficient are optimized, these gears can prevent back-driving, enhancing safety in certain setups.

- Smooth and Quiet Operation: The sliding contact between worm and wheel ensures quieter performance compared to other gear types.

These characteristics make worm and wheel gears a versatile choice for both industrial and precision applications.

Applications of Worm and Wheel Gears

Worm and wheel gears are employed in a wide range of scenarios, including:

- Speed Reducers: Common in machinery requiring controlled output speeds.

- Elevators: Providing reliable lifting mechanisms.

- Machine Tools: Ensuring precision and power transmission.

- Chain Blocks: Facilitating heavy lifting with compact gearing.

- Fishing Reels: Offering smooth, high-ratio control.

- Automotive Power Steering: Enhancing vehicle maneuverability.

- Robotics and Medical Equipment: Utilizing small-module gears for precision tasks.

In Italy, industries such as automotive manufacturing, robotics, and machinery production—key sectors in regions like Emilia-Romagna and Lombardy—rely on these gears for their efficiency and reliability.

FMP Company: Your Trusted Worm and Wheel Manufacturer in Italy

At FMP Company, we pride ourselves on being a premier provider of worm and wheel gears, catering to diverse needs with our extensive product range and customization capabilities. Our offerings include:

- Single and Multi-Start Worms: Available with varying thread counts for tailored reduction ratios.

- Worm Wheels: Produced with different tooth counts and modules to suit specific applications.

- Custom Designs: Engineered to meet your unique requirements, no matter the complexity.

Can’t Find Your Model?

If you don’t see the exact worm and wheel gear you need in our product list, don’t worry—it’s likely we haven’t had the chance to upload it yet. Simply email us with your specifications, and our expert engineers will respond within 24 hours with a solution tailored to your needs. Whether you’re in Milan, Turin, or anywhere else in Italy, we’re here to support you with fast, personalized service.

Technical Considerations for Worm and Wheel Gears

Designing an effective worm and wheel system requires attention to several critical parameters:

- Module: Defines the size of the gear teeth.

- Pressure Angle: Influences load capacity and efficiency.

- Number of Teeth on the Worm Wheel: Determines the reduction ratio alongside the worm’s thread count.

- Number of Threads on the Worm: Single, double, or triple starts affect speed and torque output.

- Pitch Diameter of the Worm: Impacts the gear’s geometry.

- Center Distance: Ensures proper alignment between shafts.

For example, a system with a module of 3, a worm pitch diameter of 44 mm, a center distance of 67 mm, and a worm wheel with 30 teeth can achieve reduction ratios like 30:1 (single-thread worm) or 15:1 (double-thread worm), adjustable by varying the thread count.