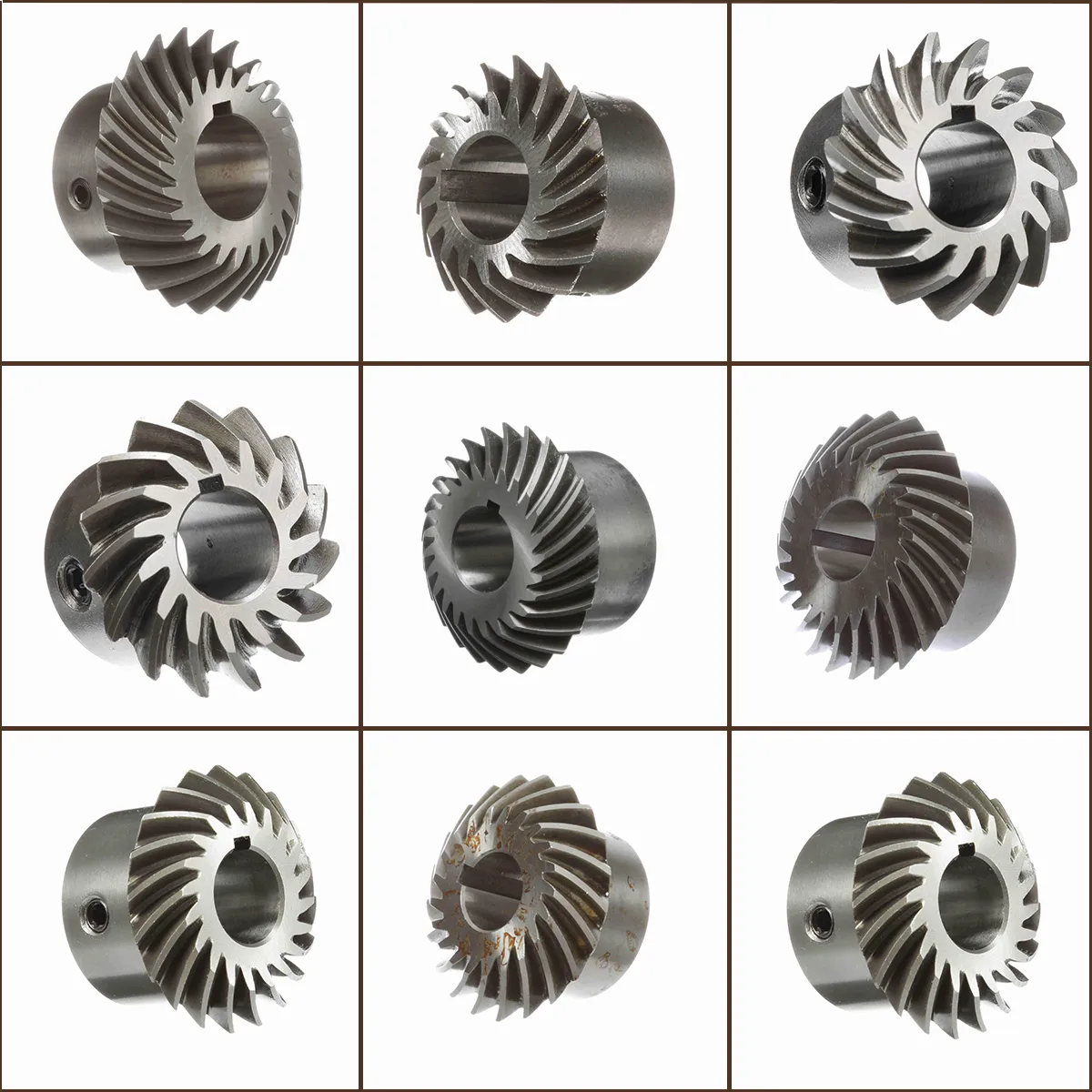

Spiral Miter Gears are a type of engranaje cónico with helical teeth designed to transmit power between intersecting shafts at a right angle, offering smoother operation and higher load capacity compared to straight miter gears. At FMP Company, we manufacture a wide variety of Spiral Miter Gears and also offer customization to meet your specific needs. If you don’t find the model you’re looking for in our product list, it may not have been uploaded yet—please feel free to email us with your requirements, and our engineers will respond within 24 hours.

Spiral Miter Gear Specifications

| Model | Module | Teeth | Spiral Direction | Pitch Diameter (mm) | Bore Diameter (mm) | Face Width (mm) | Material | Pressure Angle | Helix Angle | Solicitud |

| SMG-20-2-RH | 2 | 20 | Right Hand | 40 | 12 | 9 | Hardened Steel | 20° | 35° | General industrial machinery |

| SMG-25-3-LH | 3 | 25 | Left Hand | 75 | 20 | 15 | Carburized Steel | 20° | 35° | High-torque transmission |

| SMG-15-1.5-RH | 1.5 | 15 | Right Hand | 22.5 | 8 | 7 | Stainless Steel (SUS303) | 20° | 35° | Food processing equipment |

| SMG-30-4-LH | 4 | 30 | Left Hand | 120 | 25 | 20 | Alloy Steel (SCM415) | 20° | 35° | Heavy-duty conveyors |

| SMG-18-2.5-RH | 2.5 | 18 | Right Hand | 45 | 15 | 12 | Hardened Steel (Black Oxide) | 20° | 35° | Automotive systems |

| SMG-12-1-RH | 1 | 12 | Right Hand | 12 | 6 | 5 | Brass | 20° | 35° | Precision instruments |

| SMG-35-5-LH | 5 | 35 | Left Hand | 175 | 30 | 25 | Hardened Steel | 20° | 35° | Mining equipment |

| SMG-16-2-LH | 2 | 16 | Left Hand | 32 | 10 | 8 | Stainless Steel (SUS304) | 20° | 35° | Marine applications |

| SMG-22-3-RH | 3 | 22 | Right Hand | 66 | 18 | 14 | Alloy Steel (SCM435) | 20° | 35° | Robotics |

| SMG-28-4-RH | 4 | 28 | Right Hand | 112 | 22 | 18 | Carburized Steel | 20° | 35° | Construction machinery |

Features of Spiral Miter Gears

- Helical Tooth Design: Spiral Miter Gears feature helical teeth that are curved, allowing for gradual engagement, smoother operation, and reduced noise compared to straight-cut gears.

- High Load Capacity: The spiral tooth configuration distributes forces more evenly across the gear teeth, enabling these gears to handle higher torque and heavier loads effectively.

- Right-Angle Power Transmission: These gears are designed to transmit power between two shafts intersecting at a 90-degree angle, making them ideal for compact mechanical systems.

- Improved Efficiency: The helical design minimizes vibration and backlash, resulting in greater efficiency and precision in power transfer applications.

- Durability and Longevity: Made from high-quality materials and engineered for optimal tooth contact, Spiral Miter Gears offer enhanced wear resistance and a longer service life.

Acerca de FMP

FMP es un fabricante italiano líder de engranajes y cremalleras, reconocido por su experiencia en la producción de componentes estándar y soluciones a medida. Además de nuestra gama de piezas estándar, FMP se especializa en la fabricación de engranajes estándar y especializados basados en planos o muestras proporcionadas por nuestros clientes. Nuestros engranajes están disponibles en una variedad de materiales, incluyendo acero al carbono, acero inoxidable, aluminio, cobre, latón y configuraciones de plástico helicoidal o recto. Si necesita engranajes personalizados, no dude en contactarnos por correo electrónico. El equipo de ingenieros profesionales de FMP responderá a su consulta en 24 horas.