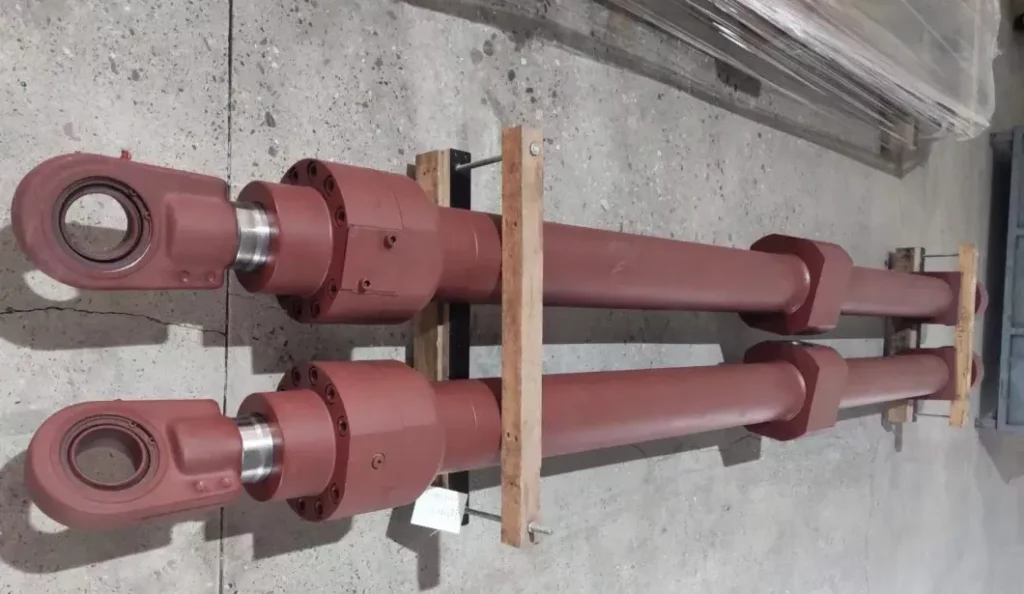

Hydraulic Cylinder for Injection Molding Machine

The Hydraulic Cylinder for Injection Molding Machine is a vital hydraulic component designed to provide the precise force and control necessary for various functions within the injection molding process. This cylinder plays a crucial role in ensuring the efficient injection, holding, and ejection of molten plastic materials into molds, contributing to high-quality production and productivity.

Key Features:

- High Force Output: Engineered to generate substantial hydraulic force, this cylinder effectively handles the pressures required for injecting molten plastic, ensuring accurate and consistent filling of molds.

- Robust Construction: Made from high-strength materials, it is built to withstand the extreme pressures and temperatures associated with injection molding, ensuring durability and reliability over time.

- Smooth Operation: The advanced hydraulic design enables smooth and controlled movements, enhancing the efficiency of the injection cycle and reducing cycle times.

- Versatile Application: Suitable for a wide range of injection molding machines, this hydraulic cylinder supports various molding processes, including thermoplastics and thermosets.

- Low Maintenance Requirements: Designed for minimal wear and tear, the hydraulic cylinder requires less maintenance, reducing downtime and contributing to increased production efficiency.

The Hydraulic Cylinder for Injection Molding Machine is an essential component that optimizes the performance and efficiency of injection molding operations, making it indispensable for manufacturers seeking high-quality and reliable production processes.

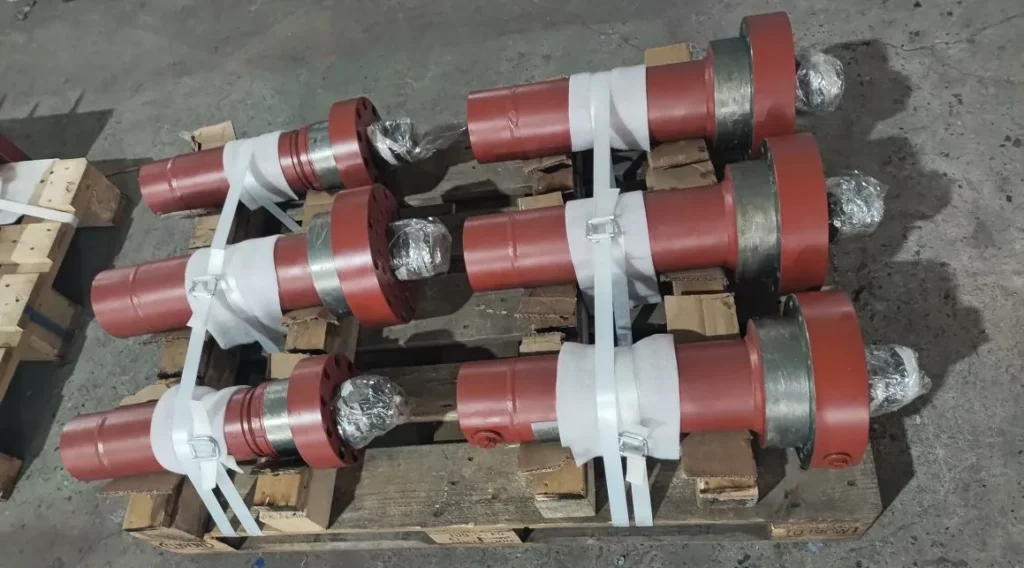

Injection Molding Machine Shooting Cylinder

The Injection Molding Machine Shooting Cylinder is a vital hydraulic component responsible for the rapid and precise injection of molten plastic into molds during the molding process. This cylinder generates the necessary force to propel the material at high speeds, ensuring accurate filling and minimizing cycle times. Constructed from high-strength materials, it is designed to withstand the extreme pressures and temperatures associated with injection molding operations, ensuring long-lasting durability and reliability. The smooth hydraulic action allows for consistent performance and control, enhancing the overall efficiency and quality of the molded products. This shooting cylinder is essential for optimizing the functionality of injection molding machines, contributing significantly to effective manufacturing processes.

| Product Name | Injection Molding Machine Shooting Cylinder |

| Features: | Drive the shooting station to move |

| Bore diameter: | 63mm~140mm |

| Rod diameter: | 36mm~90mm Stroke≤1500mm |

| Thrust force: | Maximum 384KN (Bore diameter: 140mm/pressure25MPa) |

| Applications: | Injection Molding Machine |

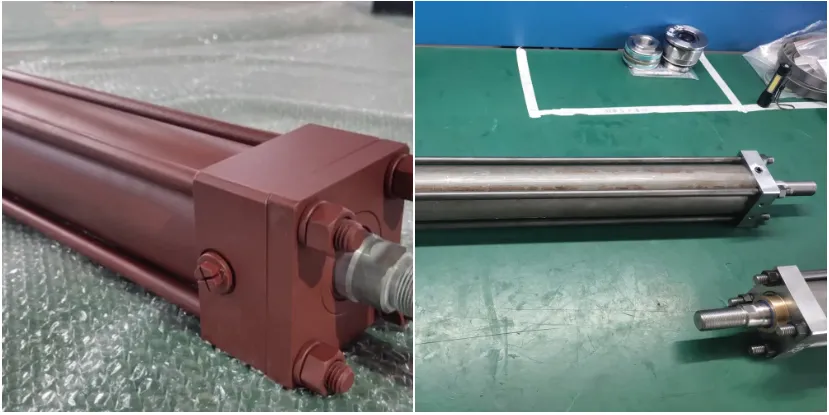

Injection Molding Machine Ejection Cylinder

Injection Molding Machine Ejection Cylinder

The Injection Molding Machine Ejection Cylinder is a crucial hydraulic component that facilitates the removal of molded parts from the injection mold after the cooling process. This cylinder generates the necessary force to push the finished product out of the mold, ensuring smooth and efficient ejection while minimizing the risk of damage to the part. Constructed from high-strength materials, it is designed to withstand the demanding conditions of injection molding operations, including high pressures and repetitive cycles. The reliable hydraulic action allows for precise control and rapid ejection, enhancing overall productivity and efficiency in the molding process. This ejection cylinder is essential for optimizing the functionality of injection molding machines, contributing significantly to effective manufacturing workflows.

| Product Name | Injection Molding Machine Ejection Cylinder |

| Features: | Eject the product formed in the mold |

| Bore diameter: | 90mm~220mm |

| Rod diameter: | 50mm~140mm Stroke≤600mm |

| Thrust force: | Maximum 760KN (Bore diameter: 220mm/pressure10MPa) |

| Applications: | Injection Molding Machine |

Injection Molding Machine Mold Opening and Closing Cylinder

The Injection Molding Machine Mold Opening and Closing Cylinder is a critical hydraulic component responsible for the precise and efficient operation of opening and closing the mold during the injection molding process. This cylinder generates the necessary force to smoothly separate and align the mold halves, ensuring accurate positioning and minimal cycle times. Constructed from high-strength materials, it is designed to withstand the high pressures and repetitive motions typical in injection molding operations, ensuring durability and reliability. The hydraulic action allows for controlled movements, enhancing overall safety and efficiency in the molding process. This cylinder is essential for optimizing the functionality of injection molding machines, contributing significantly to effective production workflows.

| Product Name | Injection Molding Machine Mold Opening and Closing Cylinder |

| Features: | Control the opening and closing of the mold |

| Bore diameter: | 50mm~140mm |

| Rod diameter: | 28mm~100mm Stroke≤700mm |

| Thrust force: | Maximum 384KN (Bore diameter: 140mm/pressure25MPa) |

| Applications: | Injection Molding Machine |

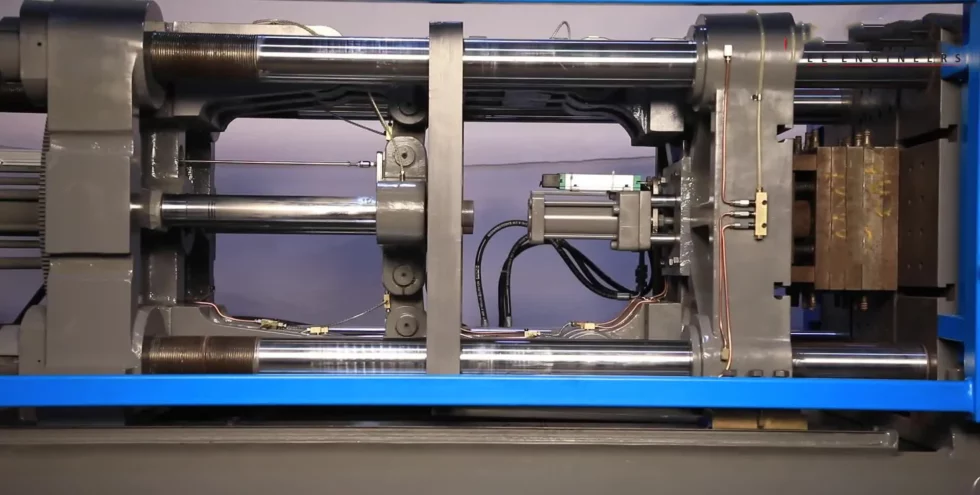

Injection Molding Machine Reciprocating Cylinder

Injection Molding Machine Reciprocating Cylinder

The Injection Molding Machine Reciprocating Cylinder is a vital hydraulic component designed to facilitate the back-and-forth motion required during the injection process. This cylinder provides the necessary force to move the injection unit smoothly, allowing for precise control when injecting molten plastic into the mold. Constructed from high-strength materials, it is engineered to withstand the high pressures and rigorous conditions typical of injection molding operations, ensuring durability and reliability. The efficient hydraulic action enables rapid response times, enhancing overall productivity and consistency in the molding process. This reciprocating cylinder is essential for optimizing the functionality of injection molding machines, contributing significantly to effective manufacturing operations.

| Product Name | Injection Molding Machine Reciprocating Cylinder |

| Features: | Quick mold shifting, also called mold shifting cylinder |

| Bore diameter: | 63mm~180mm |

| Rod diameter: | 45mm~125mm Stroke≤4000mm |

| Thrust force: | Maximum 407KN (Bore diameter: 180mm/pressure16MPa) |

| Applications: | Injection Molding Machine |

Advantages of Injection Molding Machine Hydraulic Cylinder

Injection molding machines (IMM) rely heavily on hydraulic cylinders to perform critical functions such as clamping, injection, ejection, and mold adjustment. The hydraulic cylinders in these machines play a key role in providing the high force and precision necessary for efficient plastic molding operations. Below are the key advantages of hydraulic cylinders used in injection molding machines:

1. High Force Output

Injection molding requires the application of significant force to close the mold, inject molten plastic, and eject the finished part. Hydraulic cylinders can generate extremely high forces relative to their size, making them ideal for tasks like clamping large molds or injecting plastic at high pressures. The ability to produce these high forces ensures that the machine can handle large and complex molds effectively.

2. Precision and Control

Hydraulic cylinders offer precise control over movements, which is crucial in injection molding operations. The precise control allows for accurate clamping force application, consistent injection speeds, and accurate mold positioning, ensuring high-quality finished parts with minimal defects. This is especially important for producing intricate, tight-tolerance components in industries like automotive, medical, and electronics.

3. Smooth and Steady Operation

Hydraulic systems provide smooth, continuous motion, which helps reduce wear and tear on the machine components. In injection molding, smooth operation is important for achieving consistent cycle times and preventing defects in the molded parts. Hydraulic cylinders’ ability to generate smooth motion ensures reliable and repeatable operation, contributing to high-quality production and lower defect rates.

4. Fast Response Times

Hydraulic cylinders can operate quickly and efficiently, providing fast response times for clamping, injection, and ejection functions. The speed of hydraulic actuators allows for faster production cycles, leading to increased throughput in injection molding operations. This is especially beneficial in high-volume production environments where reducing cycle time can significantly improve overall efficiency.

5. Energy Efficiency

Hydraulic systems are energy-efficient because they can generate significant force with relatively low power input, especially when compared to pneumatic or mechanical systems. This is particularly advantageous in injection molding, where energy costs can be a significant part of the operational expenses. Furthermore, the ability to precisely control the hydraulic flow allows for the use of energy only when needed, improving efficiency.

6. Durability and Reliability

Hydraulic cylinders used in injection molding machines are designed for durability and reliability in harsh industrial environments. These cylinders are typically made from high-strength alloys and are equipped with seals that prevent contamination, extend service life, and reduce the need for frequent maintenance. This durability is crucial in maintaining consistent performance over time and minimizing downtime for repairs.

7. Compact Design

Hydraulic cylinders provide high force in a compact design. This space efficiency is valuable in injection molding machines, where space constraints may limit the size of components. The compact nature of hydraulic systems allows for a more compact machine layout, optimizing floor space while still delivering the required force for efficient operation.

8. Customization for Specific Needs

Hydraulic cylinders can be customized to meet the specific needs of different injection molding applications. This includes variations in stroke length, pressure ratings, and mounting configurations, ensuring that the cylinders are suited to the particular requirements of a molding process. Whether it’s a large industrial mold or a small, intricate part, hydraulic cylinders can be tailored to provide the necessary force and precision.

9. Improved Mold Safety

Hydraulic cylinders contribute to the safe operation of the injection molding machine by ensuring the mold is securely clamped during the injection process. The clamping force generated by hydraulic cylinders ensures that the mold does not open prematurely or shift, which could cause defects or damage. Safety features such as pressure relief valves and overload protection systems further reduce the risk of malfunction.

10. Reduction in Maintenance Costs

Hydraulic systems generally require less maintenance than mechanical systems due to fewer moving parts subject to wear and tear. Properly maintained hydraulic cylinders can last a long time, contributing to the overall reliability of the injection molding machine. Regular maintenance, such as fluid checks and seal replacements, helps to minimize downtime and costly repairs.

Hydraulic cylinders in injection molding machines provide a range of advantages, including high force output, precise control, energy efficiency, and durability. Their ability to deliver smooth, steady, and fast operations makes them essential for maintaining high productivity and producing high-quality molded parts. The adaptability, reliability, and low maintenance requirements of hydraulic systems further enhance the performance of injection molding machines, contributing to improved overall efficiency and reduced operational costs in manufacturing.

Acerca de FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX