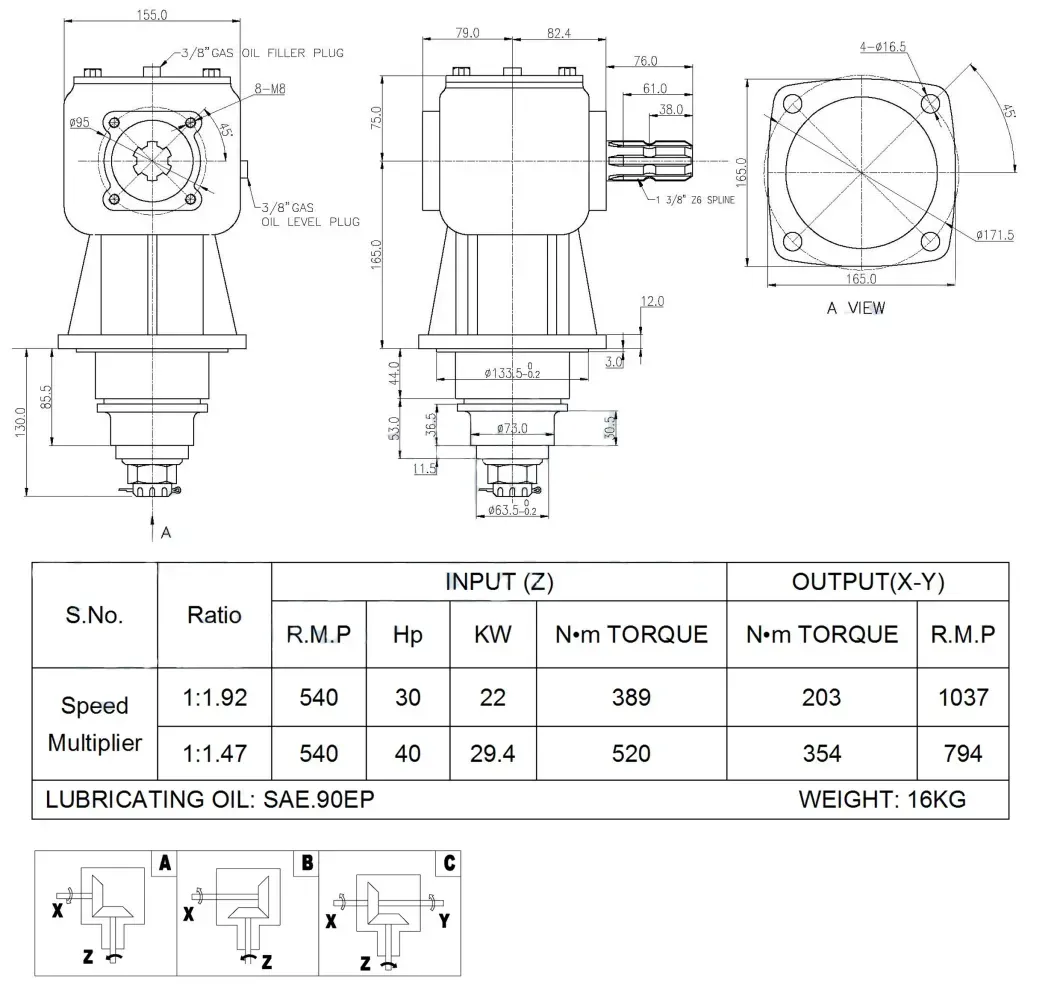

Specifications of Rotary Mower Gearbox LF-205J

| Description |

Rotary Mower Gearbox Replacement of Comer Gearbox LF-205J (speed increasing)

|

|---|---|

| Solicitud |

Mowers

|

| Consists of |

|

| Technical information |

|

| Max. input power |

22 kW

|

| Contains oil |

No

|

| Max. oil capacity |

0.8 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

| Weight |

16 kg

|

| Gear arrangement Increasing |

3

|

| Gear ratio |

1:1.92

|

| Input power kW / HP Increasing |

22 / 30 kW/HP

|

| Input shaft Increasing |

X

|

| Output Torque DaNm Increasing |

20 daNm

|

| Ratio Increasing |

1: 1.92

|

| Ratio Reducing |

1.92: 1

|

| Shaft X |

1 3/8″ (6)

|

| Shaft Z |

ASA Z12 D.P. 8/16 Ø40

|

LF-205J Rotary Mower Gearbox Parts and Structure

The LF-205J rotary mower gearbox is composed of several critical components that work seamlessly to transfer power from the engine to the mower blades, ensuring efficient cutting performance. Here’s an overview of the key parts that make up the rotary mower gearbox:

1. Housing

The housing serves as the outer shell of the gearbox, enclosing all internal components. Constructed from durable materials like cast iron or aluminum, it provides the necessary strength to protect the internal parts from external elements and wear, ensuring long-lasting performance.

2. Input Shaft

The input shaft connects the gearbox to the engine, serving as the entry point for power. It is typically designed to fit standard engine shaft sizes and is supported by high-quality bearings, enabling smooth and efficient operation during power transmission.

3. Output Shaft

The output shaft transmits power from the gearbox to the mower blades. Like the input shaft, it is designed to fit standard shaft sizes and is supported by bearings to ensure smooth and stable operation. The output shaft is essential for ensuring that the mower blades rotate with the required force for cutting.

4. Gears

The gears inside the gearbox play a vital role in transferring power from the input shaft to the output shaft. Depending on the design, rotary mower gearboxes may feature different types of gears such as:

- Spur Gears: Simple, straight-toothed gears that efficiently transfer power.

- Helical Gears: Gears with angled teeth that provide smoother and quieter operation.

- Bevel Gears: Gears designed to transmit power at a right angle, commonly used when the input and output shafts are oriented differently.

5. Bearings

Bearings support both the input and output shafts, ensuring they rotate smoothly and with minimal friction. Made from durable materials like steel or bronze, the bearings help maintain consistent performance and extend the lifespan of the gearbox.

6. Seals

Seals prevent lubricant from leaking out of the gearbox and protect the internal components from dirt, water, and other contaminants. Typically made from high-quality rubber or silicone, seals play a crucial role in maintaining the efficiency and longevity of the gearbox by keeping it properly lubricated and free from external damage.

7. Clutch

The clutch mechanism is responsible for engaging and disengaging the mower blades from the gearbox. Located on the output shaft, the clutch is usually operated by a lever or switch and ensures that the blades only rotate when needed. This feature is vital for safety and control, allowing the operator to easily disengage the blades when necessary.

The LF-205J rotary mower gearbox consists of several essential components that work in harmony to deliver reliable and efficient power transmission. By using high-quality materials and precision engineering, the gearbox ensures smooth operation, durability, and optimal performance for a clean and even cut.

Benefits of Using Rotary Mower Gearbox LF-205J

The LF-205J rotary mower gearbox offers a range of advantages that enhance the performance and longevity of your mowing equipment. Here are the key benefits of using this gearbox:

- Efficient Power Transmission The LF-205J gearbox efficiently converts the high-speed rotation from the engine into the slower, high-torque rotation needed to drive the mower blades. This results in optimized power transmission, reducing energy waste and enhancing overall efficiency.

- Smooth and Quiet Operation Designed for smooth and quiet performance, the LF-205J gearbox minimizes vibrations and noise during operation. This not only improves the operator’s comfort but also creates a more pleasant mowing experience in residential or noise-sensitive environments.

- Durability and Long-Lasting Performance Constructed from high-quality materials such as cast iron or aluminum, the LF-205J gearbox is built to withstand the rigors of heavy-duty use. Its robust design ensures extended service life, even in demanding conditions, providing reliable performance over time.

- Customizable Configurations The LF-205J gearbox is available in various configurations, including single-speed and multi-speed options, with different gear ratios and torque capacities. This flexibility allows it to be tailored to meet the specific needs of different rotary mowers and their unique applications, offering versatility across various tasks.

- Low Maintenance Requirements The LF-205J gearbox is designed for minimal maintenance, helping to reduce downtime and keep maintenance costs low. With proper lubrication and occasional inspections, this gearbox offers hassle-free operation, allowing users to focus on productivity.

- Enhanced Cutting Performance By providing consistent and reliable power to the mower blades, the LF-205J gearbox ensures a clean and even cut. This improves the mowing quality and efficiency, leading to a better overall finish and reduced time spent on the task.

The LF-205J rotary mower gearbox delivers a combination of efficiency, durability, and low-maintenance performance. Its design ensures smooth, quiet operation while offering customizable features to meet the specific needs of various applications. By providing reliable power transmission, it enhances cutting performance and reduces energy loss, making it an ideal solution for both commercial and residential rotary mowers.

PTO Shafts for Rotary Mower Gearboxes

PTO (Power Take-Off) shafts are crucial components that connect the tractor’s engine to the rotary mower gearbox, enabling efficient power transmission to drive the mower blades. When selecting a PTO shaft for a rotary mower gearbox, it is important to consider several factors to ensure optimal performance and safety. Below are the key considerations:

- Length

The length of the PTO shaft must be carefully chosen to match the distance between the tractor’s PTO output shaft and the input shaft of the rotary mower gearbox. A correctly sized PTO shaft ensures proper alignment, smooth operation, and minimizes the risk of mechanical issues. - Size and Capacity

PTO shafts come in various sizes, which should be selected based on the horsepower of the tractor and the torque requirements of the rotary mower gearbox. It’s essential to choose a PTO shaft that can handle the required power transmission without straining the driveline. - Safety Features

Due to the rotational speed and force of PTO shafts, they can be hazardous if not used properly. Select a PTO shaft equipped with safety features like a shear pin or slip clutch. These safety devices help prevent equipment damage and reduce the risk of injury in the event of a jam or overload. - Maintenance and Durability

Regular maintenance of the PTO shaft is critical to ensure its longevity and proper functionality. Choose a PTO shaft that is easy to maintain, with components that are durable and have readily available replacement parts. Regular lubrication and inspections can help extend the life of the shaft and minimize downtime.

Choosing the right PTO shaft for your rotary mower gearbox is essential for ensuring efficient and reliable power transfer from the tractor to the mower blades. By considering factors like length, size, safety features, and maintenance, you can optimize performance, prevent damage, and enhance the safety of your equipment.

Acerca de FMP

FMP, headquartered in Italy, is a renowned leader in the research, development, and manufacturing of high-quality gearboxes, reducers, and engineering machinery. With a deep commitment to innovation and technical excellence, FMP has carved a niche for itself as a pioneer in the mechanical engineering sector. The company is driven by a culture of nurturing talent and fostering creativity, making it a trusted partner for global industries seeking top-notch engineering solutions.

Diverse Product Portfolio

FMP offers a wide array of specialized products, including:

- Spiral Bevel Gearboxes

- Spur Gearboxes

- Worm Gearboxes

- Cylindrical Gearboxes

- High-Pressure Cast Valve Bodies and Housings

These products are designed and engineered to meet the rigorous demands of various industrial applications, ensuring high performance, efficiency, and reliability.

Wide-Ranging Applications

FMP’s products find applications across a diverse range of industries, including:

- Agriculture: FMP gearboxes are widely used in agricultural machinery, including rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors. These robust gearboxes help improve the efficiency and reliability of machinery used for essential farming tasks.

- Industrial Equipment: FMP also supplies gearboxes and related components for industrial machinery, such as oil extraction equipment, marine applications, and hydraulic systems for engineering projects, ensuring high performance in critical applications.

- Hydraulic Engineering: The company provides a variety of hydraulic components, serving industries that require precision and reliability, from construction to energy sectors.

Advanced Manufacturing Processes

FMP is proud of its robust technical capabilities and advanced manufacturing processes. The company employs a highly skilled workforce, cutting-edge technology, and a meticulous production process to deliver top-tier products:

- Product Design: FMP works closely with customers to develop tailored solutions, ensuring that each product meets specific requirements in terms of gearbox type, material, and dimensions.

- Material Preparation: FMP selects only the highest-grade materials such as cast iron and aluminum alloys, ensuring durability and longevity in all their products.

- Precision Machining: Components like gears, shafts, and housings undergo advanced machining techniques, including turning, milling, and grinding, to achieve precise tolerances and optimal performance.

- Assembly: Gears, bearings, and shafts are expertly assembled into the housing, ensuring precise alignment and adequate lubrication for long-lasting operation.

- Heat Treatment: Gearboxes undergo heat treatment processes to enhance strength and wear resistance, ensuring they stand up to demanding operational conditions.

- Surface Treatment: To improve corrosion resistance and enhance the appearance of the gearboxes, FMP applies surface treatments like polishing and powder coating.

- Quality Control: Rigorous inspections and testing are carried out at every stage of production to ensure each product meets strict performance and durability standards. FMP’s quality control processes ensure that each gearbox performs reliably over time.

Industry Reputation

FMP’s unwavering dedication to quality, innovation, and customer satisfaction has earned it an exceptional reputation within the manufacturing industry. The company’s philosophy revolves around craftsmanship, technological advancement, and providing long-term value to clients. FMP’s success is built on the continuous pursuit of excellence, ensuring that it meets the ever-evolving needs of the industries it serves.

Partner with Us

FMP is always open to collaboration opportunities with global clients and partners. Whether you are looking for customized solutions or off-the-shelf products, FMP is committed to providing high-quality gearboxes and engineering components that exceed expectations. For inquiries about our products and services, please don’t hesitate to contact us via phone or email. We are here to deliver tailored solutions that meet your unique needs and drive your business forward.

Autor: CX