|

|

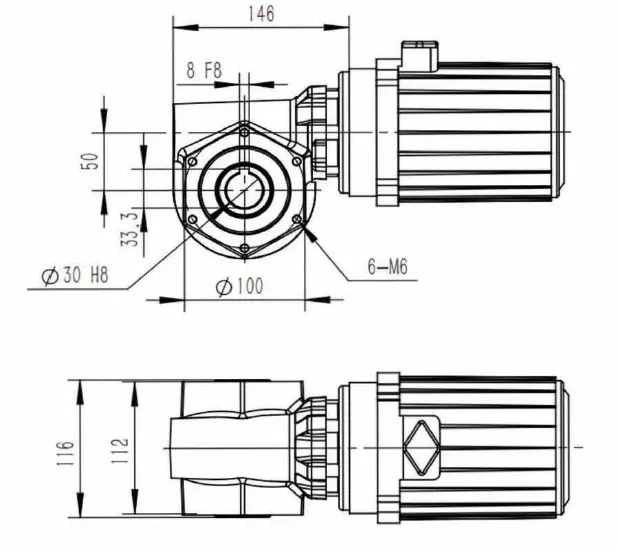

Specifications of XRV050 Car Washer Worm Gear Reducer

| Type | Ratio | Flange | Power |

| XRV050 | 5 7.5 10 12 15 20 30 40 50 60 80 100 | 71B14 | 0.18KW 0.25KW 0.37KW 0.55KW 0.75KW 1.1KW |

| 80B14 |

| Type | i | n2/r/min | Mn2/Nm | Fr2/N | Motor | P1/kw | L/mm |

| XRV050 | 5 | 280 | 17 | 1577 | 7134 | 0.55 | 180 |

| 280 | 23 | 1577 | 8024 | 0.75 | 205 | ||

| 7.5 | 187 | 25 | 1805 | 7134 | 0.55 | 180 | |

| 187 | 34 | 1805 | 8024 | 0.75 | 205 | ||

| 10 | 140 | 22 | 1987 | 7124 | 0.37 | 180 | |

| 140 | 32 | 1987 | 7134 | 0.55 | 180 | ||

| 140 | 44 | 1987 | 8024 | 0.75 | 205 | ||

| 12 | 117 | 26 | 2016 | 7124 | 0.37 | 180 | |

| 117 | 33 | 2016 | 7134 | 0.55 | 205 | ||

| 117 | 48 | 2016 | 8024 | 0.75 | 205 | ||

| 15 | 93 | 31 | 2274 | 7124 | 0.37 | 180 | |

| 93 | 46 | 2274 | 7134 | 0.55 | 180 | ||

| 93 | 63 | 2274 | 8024 | 0.75 | 205 | ||

| 20 | 70 | 27 | 2503 | 7114 | 0.25 | 180 | |

| 70 | 40 | 2503 | 7124 | 0.37 | 180 | ||

| 70 | 59 | 2503 | 7134 | 0.55 | 180 | ||

| 70 | 81 | 2503 | 8024 | 0.75 | 205 | ||

| 25 | 56 | 32 | 2696 | 7114 | 0.25 | 180 | |

| 56 | 48 | 2696 | 7124 | 0.37 | 180 | ||

| 56 | 71 | 2696 | 7134 | 0.55 | 180 | ||

| 30 | 47 | 37 | 2865 | 7114 | 0.25 | 180 | |

| 47 | 55 | 2865 | 7124 | 0.37 | 180 | ||

| 47 | 81 | 2865 | 7134 | 0.55 | 180 | ||

| 40 | 35 | 33 | 3153 | 7114 | 0.25 | 180 | |

| 35 | 46 | 3153 | 7124 | 0.37 | 180 | ||

| 35 | 68 | 3153 | 7134 | 0.55 | 180 | ||

| 50 | 28 | 54 | 3397 | 7114 | 0.25 | 180 | |

| 28 | 72 | 3397 | 7124 | 0.37 | 180 | ||

| 28 | 80 | 3397 | 7134 | 0.55 | 180 | ||

| 52 | 27 | 55 | 3482 | 7114 | 0.25 | 180 | |

| 27 | 73 | 3482 | 7124 | 0.37 | 180 | ||

| 27 | 82 | 3482 | 7134 | 0.55 | 180 | ||

| 60 | 23 | 60 | 3610 | 7114 | 0.25 | 180 | |

| 23 | 75 | 3610 | 7124 | 0.37 | 180 | ||

| 23 | 84 | 3610 | 7134 | 0.55 | 180 | ||

| 80 | 18 | 64 | 3973 | 7114 | 0.25 | 180 | |

| 18 | 77 | 3973 | 7124 | 0.37 | 180 | ||

| 18 | 89 | 3973 | 7134 | 0.55 | 180 | ||

| 100 | 14 | 68 | 4280 | 7114 | 0.25 | 180 | |

| 14 | 79 | 4280 | 7124 | 0.37 | 180 | ||

| 14 | 93 | 4280 | 7134 | 0.55 | 180 |

About Car Washing Machine

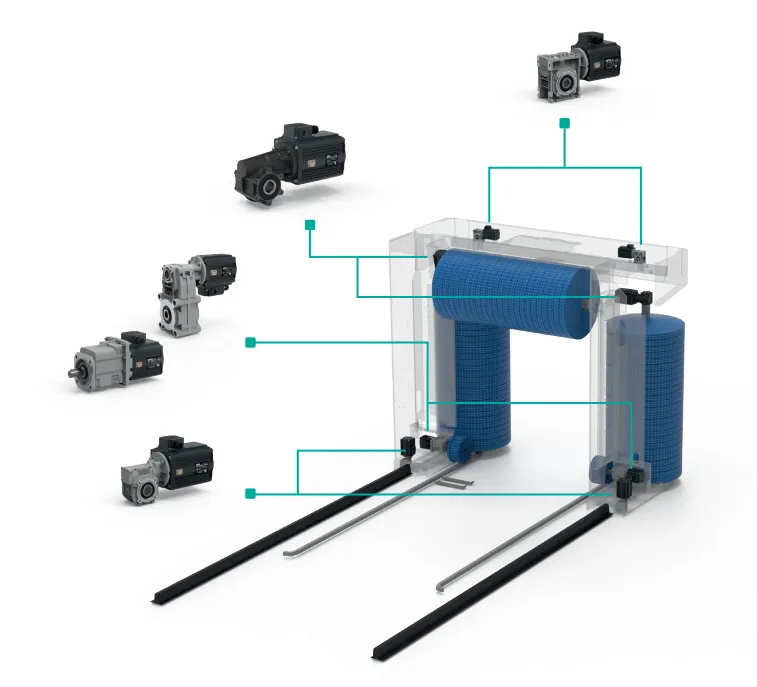

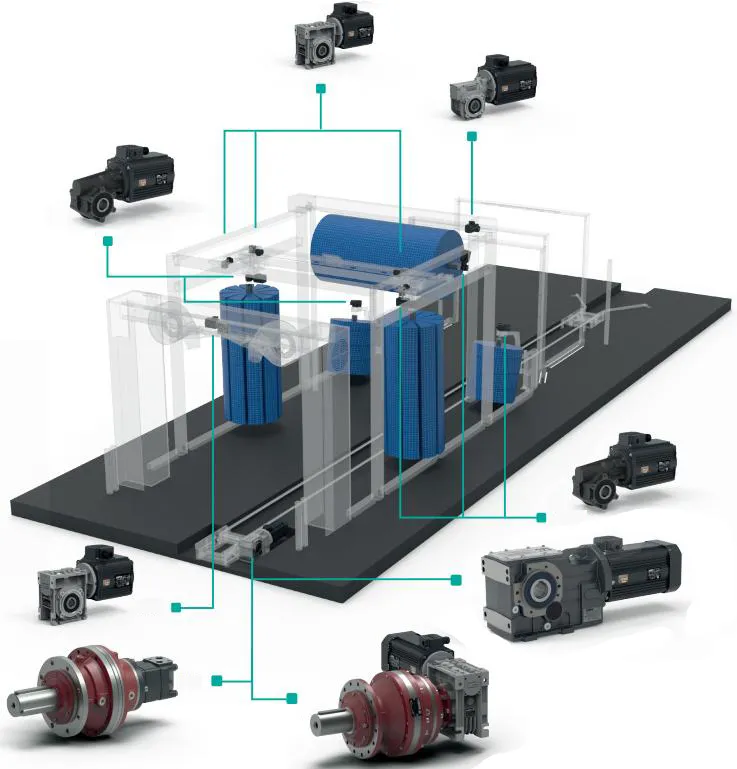

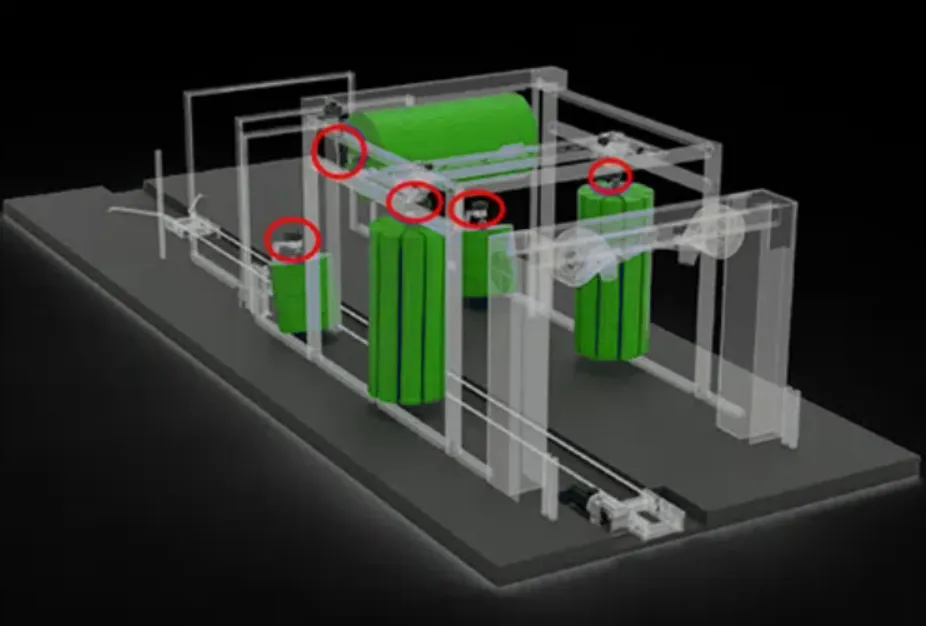

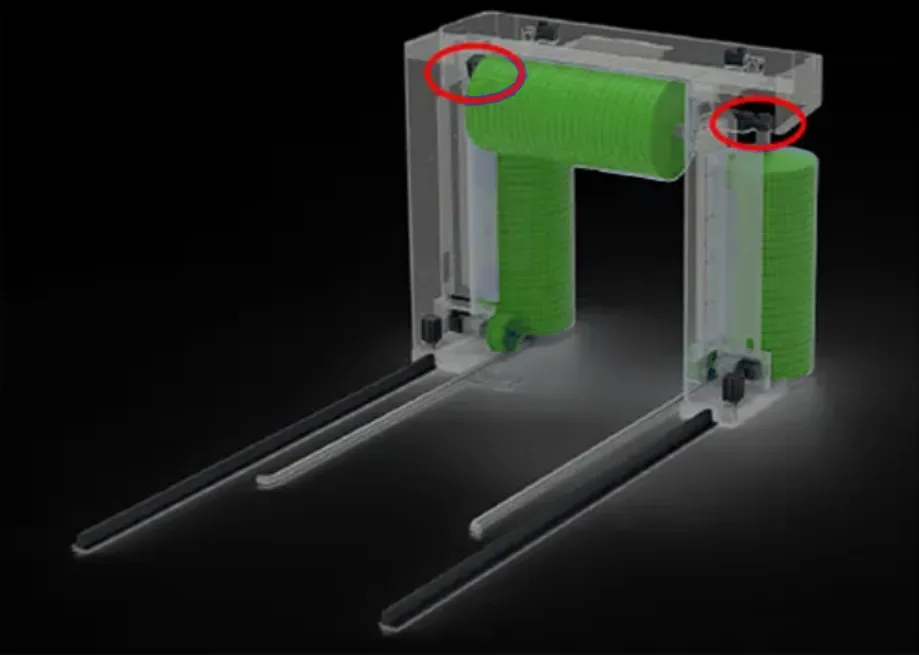

A car washing machine is an automated device that uses computer control to operate brushes and high-pressure water for washing vehicles. As a car owner, when you visit a car wash, you’ll notice various types of transmission systems, including horizontal brushes, vertical brushes, and wheel brushes. These systems, which do not require manual input, are powered by the car wash machine’s reducer. The reducer plays a crucial role in the car wash equipment by reducing the motor’s speed and providing steady power to the water spray and rotating brush systems. This ensures that the right speed and torque are delivered for efficient operation of the car wash components, guaranteeing stable performance and effective cleaning in various environments.

|

|

Automatic Tumble Car Washers: These advanced washers utilize large rotating brushes to clean the vehicle thoroughly. To ensure optimal performance, a worm gear reducer is used to drive the brushes, allowing them to rotate at the ideal speed for removing dirt and debris from the vehicle’s surface.

Tunnel Car Wash Systems: In these systems, vehicles move through a fixed tunnel equipped with advanced cleaning and waxing machinery. Worm gear motors are typically used to drive the rotating brushes or rollers within the system, providing reliable power output for consistent cleaning.

Touch and Touchless Car Wash Systems: Modern car wash systems offer both touch and touchless options to meet different preferences. In the touch system, rotating brushes physically contact the vehicle’s surface to clean it. Meanwhile, touchless systems use high-pressure water jets to clean the vehicle. The worm gearbox in touch systems ensures precise control over brush speed and pressure, ensuring effective cleaning without damaging the vehicle’s paint.

How do automatic car wash gear motors work?

Automatic car wash gear motors are essential components in the operation of automatic car wash systems. They provide the necessary power for the movement of various parts involved in the washing process, such as brushes, conveyors, and spray systems. While designs may vary, here’s a general overview of how automatic car wash gear motors work:

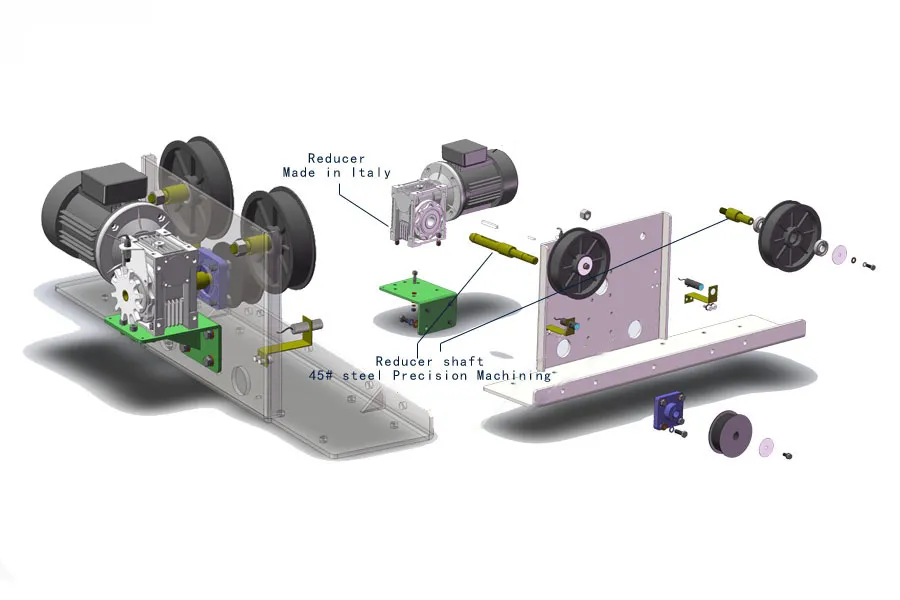

- Motor: The gear motor uses an electric motor as its primary power source. Typically, the motor is either an AC motor for commercial car washes or a DC motor for smaller or portable systems.

- Gearbox: The motor is connected to a gearbox, which reduces the motor’s high-speed rotation to a lower speed with higher torque. The gearbox contains various gears—such as worm gears, planetary gears, or spur gears—depending on the design. These gears work together to achieve the desired speed and torque conversion.

- Power Transmission: The output shaft of the gearbox is connected to a system of belts, chains, or direct coupling, depending on the design of the car wash system. This transmission system transfers the rotational motion from the gear motor to the components that need to move, such as the brushes and conveyor belts.

- Control System: The gear motor is controlled by a central control system that manages the operation of the car wash. The control system receives input from sensors, switches, or automatic triggers and sends signals to the gear motor to start specific operations at the right time. For example, when a vehicle enters the car wash, the system may trigger the motor to start the conveyor or activate the brushes.

- Safety Features: Automatic car wash gear motors typically include safety features to prevent damage or accidents. These may include limit switches or sensors to detect obstacles or excessive force, emergency stop buttons, and overload protection mechanisms. These safety functions help ensure that the motor operates within safe parameters and protects both the equipment and the vehicle being washed.

By combining the motor’s power, the gearbox’s speed reduction, and controlled power transmission, the automatic car wash gear motor synchronizes the movement of various components, ensuring an efficient washing process.

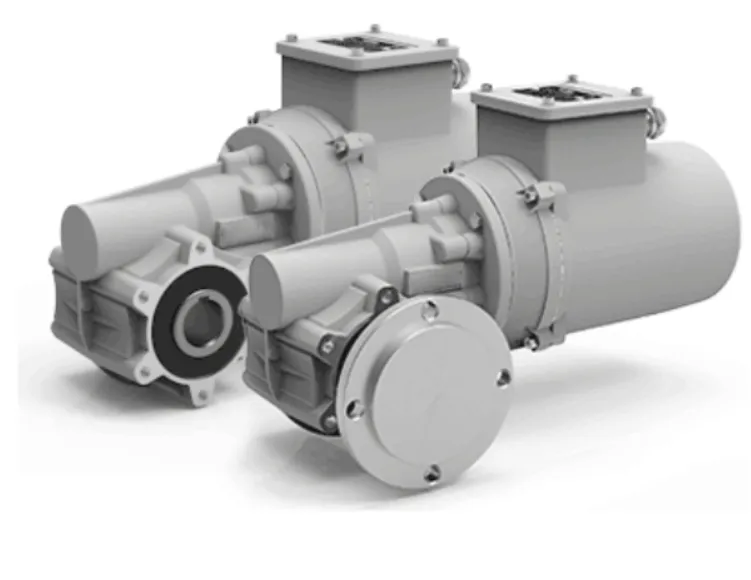

The gear reducers developed and produced by FMP for car wash machines are specifically designed for use in current mainstream car wash equipment. They feature easy installation, low noise, long lifespan, and excellent protection. The waterproof gear reducers provide a higher protection level than conventional worm gear reducers and are tailored for the modern car wash industry.

|

|

The car washing machine reducer produced by FMP has the following performance and advantages:

Special motor configuration power 0.25KW, 0.37KW, 0.55KW, 0.75KW and 2.2KW, etc.;

Various types of flanges can be selected according to customer needs;

Each module adopts modular design, and the parts are more universal;

The speed ratio range is wide, with more speed ratio options than general models;

The output end is made of 304 stainless steel to ensure that it will not rust during use;

The body structure is compact and convenient for installation in various environments;

Special full synthetic lubricant, no need to change oil for life;

The body surface is sprayed with plastic, with good corrosion resistance, beautiful and practical;

The input and output ends are sealed with oil seals to ensure sealing performance;

The worm wheel is made of wear-resistant tin bronze, and the worm is carburized and quenched with strong hardness;

The protection level is IP67, which can be used in various indoor and outdoor use scenarios and harsh working environments;