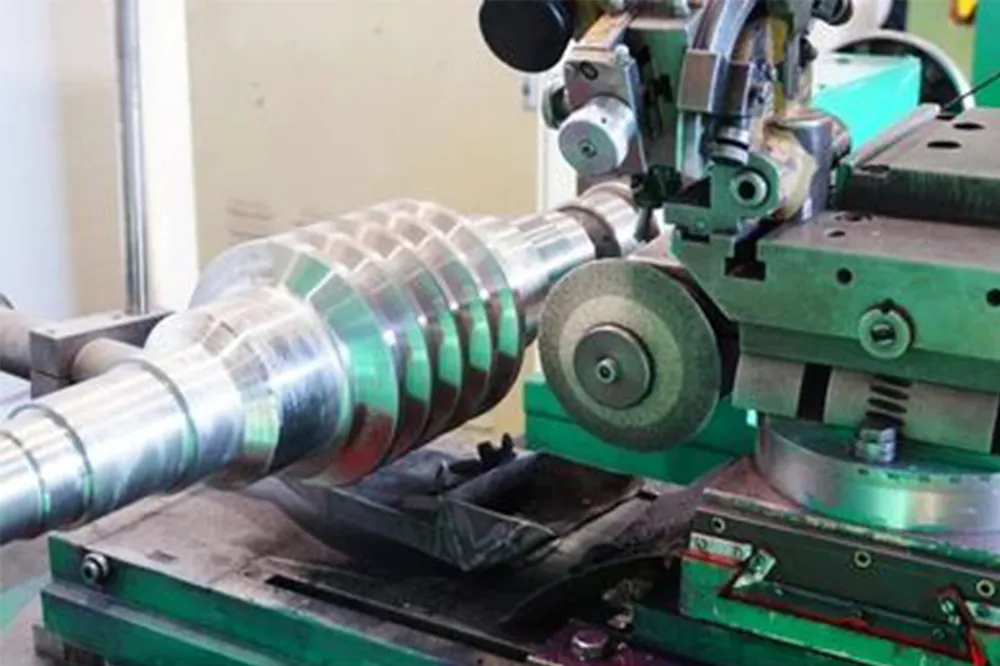

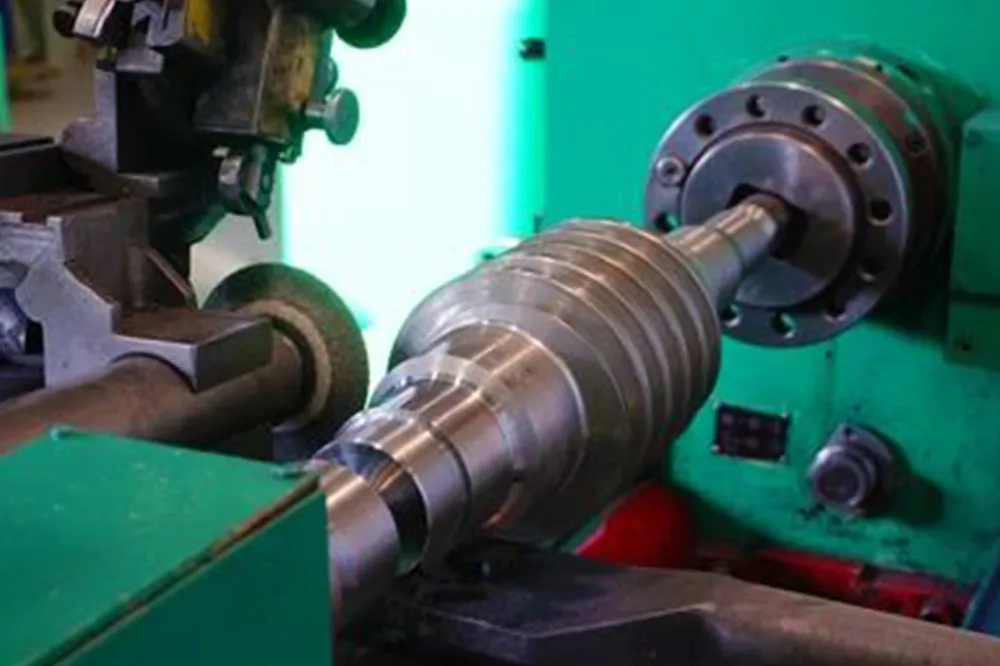

A worm gear shaft is a critical mechanical component used in various industries to transmit power and motion between non-parallel shafts, offering high torque and smooth operation. At FMP Company, we specialize in manufacturing a wide range of worm gear shafts, tailored to meet diverse application needs, and we also offer custom solutions to match your specific requirements. If you don’t find the model you need in our product list, it’s likely we haven’t uploaded it yet—please feel free to email us with your desired specifications, and our engineers will respond within 24 hours with a personalized solution.

|

|

|

|

|

|

Specifications of Worm Gear Shaft

| Model Number | M1,M2,M3,M4,M5,M8,M12 and etc. |

| Material | Brass, C45 steel, Stainless steel, Copper, POM, Aluminum, Alloy, and so on |

| Surface treatment | Zinc-plated, Nickel plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating, and Electrophoresis |

| Standard | ISO, DIN, ANSI, JIS, BS, and Non-standard. |

| Precision | DIN6,DIN7,DIN8,DIN9. |

| Teeth treatment | Hardened, Milled, or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sandblast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, L/C |

| Production lead time | 20 business days for the sample,25 days for the bulk |

| Samples | Sample price range from $2 to $100. sample express request paid by clients |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

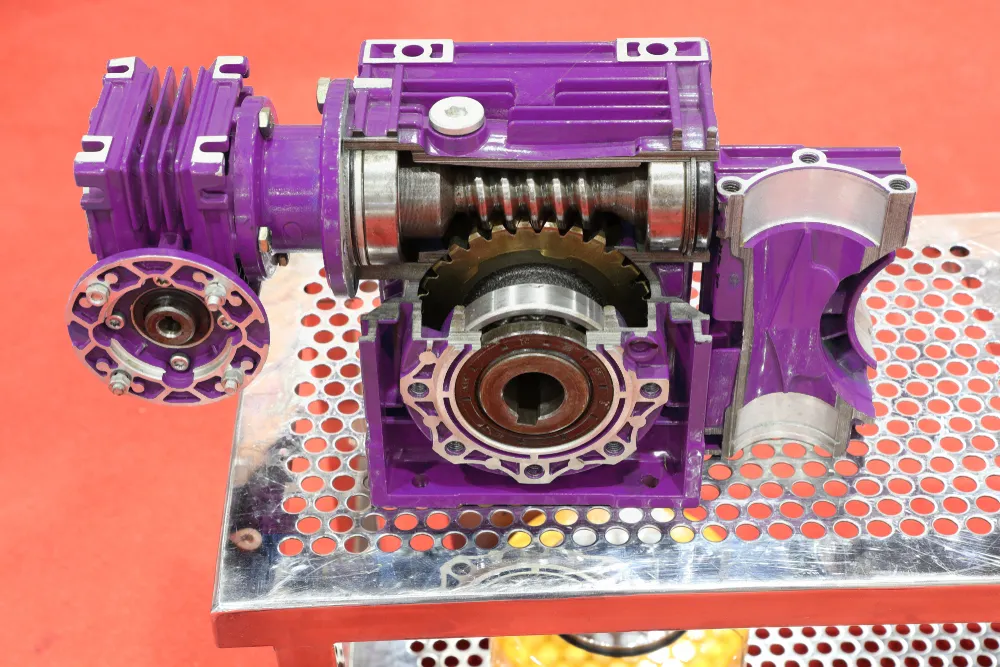

The Relationship Between Worm Gear Shaft and Worm Gearbox

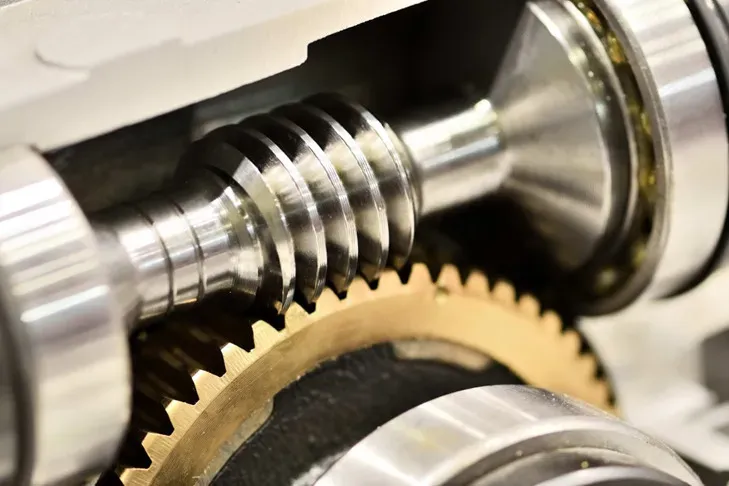

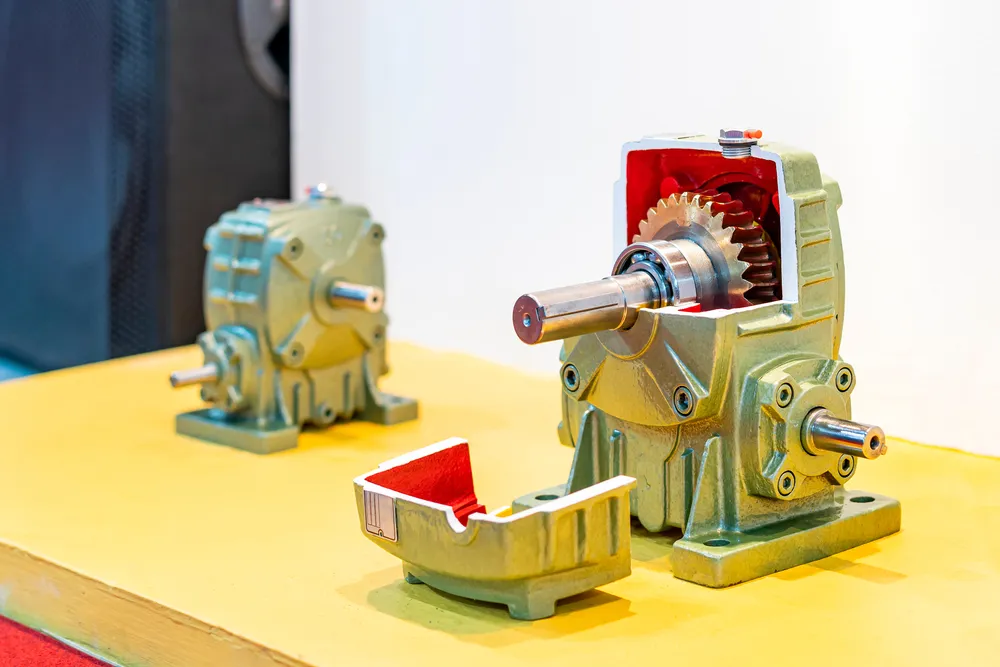

A worm gearbox is a specialized gear system designed to reduce rotational speed while increasing torque, making it ideal for various industrial applications. At its core, it consists of two primary components: the worm and the worm gear. The worm, which resembles a screw, is mounted on the input shaft (often referred to as the worm shaft). This worm meshes with the worm gear, a gear wheel with teeth specifically designed to engage with the worm. The worm gear, in turn, is mounted on the output shaft, which is sometimes called the worm gear shaft.

The relationship between the worm gear shaft and the worm gearbox is straightforward yet critical: the worm gear shaft serves as the output shaft of the worm gearbox. It carries the worm gear, which is driven by the worm. This interaction allows the gearbox to convert high-speed, low-torque input (from the worm shaft) into low-speed, high-torque output (via the worm gear shaft). This unique configuration provides several advantages, including:

- High torque multiplication: Ideal for heavy-duty machinery.

- Compact design: Suitable for space-constrained applications.

- Self-locking capability: Prevents back-driving in some designs, enhancing safety.

In summary, the worm gear shaft is an integral part of the worm gearbox, playing a key role in transmitting the adjusted motion and torque to the driven equipment.

Our Company’s Worm Gearbox Offerings

At our company, we specialize in manufacturing a wide range of worm gearboxes tailored to meet diverse industrial needs. Whether you require standard models for general applications or customized solutions for specific requirements, we have the expertise and capability to deliver high-quality products. Our worm gearboxes are designed with a focus on:

- Durability: Built to withstand demanding conditions.

- Efficiency: Optimized for performance and energy savings.

- Versatility: Suitable for industries such as manufacturing, automation, and material handling.

If you have any needs for worm gearboxes—whether for conveyors, lifts, or other machinery—we invite you to contact us. Our team is ready to provide expert advice, detailed information, and personalized support to ensure you find the perfect solution for your application. Feel free to reach out today to discuss how we can assist you!

|

|

|

|