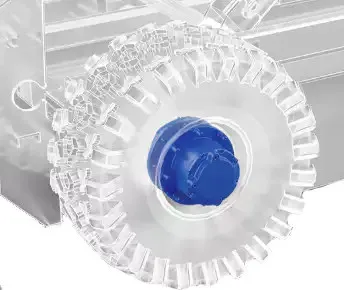

Wheel Drive Planetary Gearbox Reducer for Cranes

The wheel drive planetary gearbox reducer for cranes is a key component in providing mobility and stability to cranes. It is responsible for transmitting power from the crane’s engine to the wheels, ensuring smooth and controlled movement. Depending on the crane’s wheel configuration, multiple planetary gearboxes may be used to drive each wheel, enabling the crane to maneuver effectively in diverse work environments.

Performance Requirements for Wheel Drive in Cranes

- High Torque Capacity: The gearbox must be capable of handling the crane’s heavy loads, ensuring reliable power transmission to the wheels under demanding conditions.

- Low Noise Operation: To minimize noise pollution on job sites, the gearbox is designed for quiet operation, maintaining a peaceful working environment.

- High Efficiency: The gearbox should provide efficient power transfer, reducing energy loss and optimizing crane performance for maximum productivity.

- Durability: Built to withstand tough working environments, the gearbox must endure harsh conditions, including extreme weather and heavy-duty usage, ensuring a long service life.

- Stability: The gearbox plays a crucial role in ensuring that the crane operates on a stable platform, maintaining balance and control during lifting and moving heavy loads.

How Wheel Drive Works with Cranes

Wheel drive in cranes refers to the mechanism that propels the crane’s wheels, enabling it to move along a track or across a surface. This system typically uses electric or hydraulic motors connected to the wheels, which generate the necessary torque to move the crane. The type of drive used (hydraulic or electric) depends on the crane’s design and application requirements.

In electric wheel drive systems, electric motors supply power to the wheels via a series of gear reductions or direct drives. The motors are often powered by the crane’s main power supply or an external source. These motors can be controlled through sophisticated systems to adjust the crane’s speed, direction, and acceleration, offering precision and efficiency.

Hydraulic wheel drive systems, on the other hand, use hydraulic motors to drive the wheels. These motors are powered by hydraulic pumps, which are typically driven by a diesel or electric engine. The hydraulic drive offers strong torque and is often preferred in cranes that need to move heavy loads or operate in challenging environments where high power output and robust performance are required.

Popular Brands and Compatibility

Note: The brand names mentioned in the article are just for our convenience for customers to choose and replace the accessories of the corresponding agricultural machinery brand, and are not selling the products of that brand.

| Brand | Model | Compatibility |

|---|---|---|

| Zoomlion | QUY260 | Compatible |

| XCMG | QY50K | Compatible |

| Sany | STC250 | Compatible |

| Terex | RT555-1 | Compatible |

About FMP

FMP is a premier manufacturer specializing in the production of a wide variety of mechanical and hydraulic transmission products. Our product range includes planetary gearboxes, worm reducers, inline helical gear reducers, parallel shaft helical gear reducers, helical bevel gear reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, automobile gearboxes, power output shafts, and specialized reducers. Additionally, we offer a comprehensive selection of complementary components such as sprockets, hydraulic systems, vacuum pumps, hydraulic couplings, racks, chains, timing pulleys, UDL transmissions, V-belt pulleys, hydraulic cylinders, gear pumps, screw air compressors, and low-backlash worm reducers, among others.

Customized Solutions for Every Need

At FMP, we understand that each application is unique. That’s why we offer fully customizable solutions, including bespoke transmissions, gear motors, hydraulic systems, and motors designed to meet the specific requirements of our clients. Our flexible manufacturing capabilities enable us to create precisely engineered products tailored to ensure maximum efficiency and optimal performance for any application.

Commitment to Quality and Innovation

We are deeply committed to maintaining the highest standards of quality and reliability in every product we produce. Our advanced testing and inspection equipment, along with a highly skilled technical team, ensure that every product meets rigorous industry standards. Whether providing standard solutions or creating custom-designed products, FMP is dedicated to delivering top-quality results that perform exceptionally even in the most demanding environments.

In recent years, FMP has experienced rapid growth, fueled by our extensive production experience, robust management systems, and strong technical expertise. Our philosophy of “quality for survival and innovation for development” has been the cornerstone of our success, driving continuous improvement and growth.

Partnership for Success

At FMP, we prioritize collaboration and long-term partnerships with our clients. We work closely with our customers to deliver innovative, reliable solutions that exceed expectations. Our goal is not only to meet the needs of our clients but to forge lasting relationships based on trust, quality, and mutual success.

Focused on precision engineering, reliability, and customized services, FMP is the trusted partner for all your mechanical and hydraulic transmission needs. We look forward to collaborating with you to drive success and achieve excellence together.

Author: CX