TENV Stainless Steel Washdown NEMA Motor With Single Capacitor

Washable NEMA motor c series stainless steel washable motor is designed and manufactured according to C standard. 80-132m.0.18kw-1 5kW stainless steel frame on all external surfaces

Application: Food processing, packaging, outdoor and highly corrosive environment

Features: all outer surfaces of stainless steel motor frames, end plates, conduit boxes, shafts and bases, four condensate drains in each end plate, conduit box gasket lip seals. It is especially suitable for highly corrosive environments where paint or other surface treatments cannot maintain working conditions: the motor is designed and manufactured according to IEC standards, and all external surfaces are stainless steel, which is very suitable for driving food processing, packaging, outdoor and highly corrosive environments.

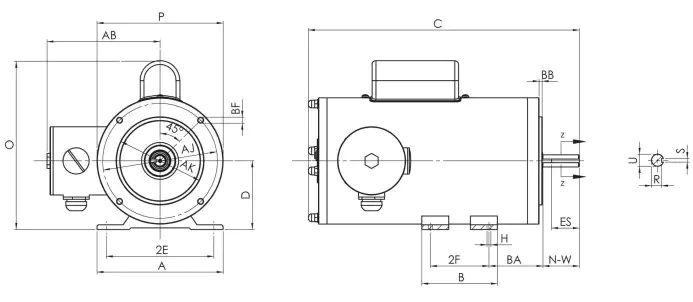

| Frame | A | BB | BA | N-W | U | R | S | ES | E | 2F | B | H | BF | AJ | AK | P | AB | D | O |

| 56C | 6.5 | 0.16 | 2.75 | 1.88 | 0.625 | 0.517 | 0.188 | 1.41 | 2.44 | 3 | 3.87 | 0.34 | 3/8-16 | 5.875 | 4.5 | 6.46 | 5.79 | 3.504 | 8.51 |

| 143TC | 6.5 | 0.16 | 2.75 | 2.25 | 0.771 | 0.771 | 0.188 | 1.41 | 2.75 | 4 | 4.87 | 4.87 | 3/8-16 | 5.875 | 4.5 | 6.46 | 5.79 | 3.504 | 8.51 |

| 145TC | 6.5 | 0.16 | 2.75 | 2.25 | 0.771 | 0.771 | 0.188 | 1.41 | 2.75 | 5 | 5.87 | 5.87 | 3/8-16 | 5.875 | 4.5 | 6.46 | 5.79 | 3.504 | 8.51 |

Feature of stainless steel NEMA motor

- 1/2 – 30 HP (three-phase), 1/2 – 1 HP (single-phase)

- 56C – 286tc frame

- 115/230, 230/460, 575 Volts

- Enclosure: tefc /tenv

- Ip69 water

- Available inverter operation

- All stainless steel structure

- Epoxy resin encapsulated winding and conduit box

- Two mechanical seals on the output shaft

- 360-degree rotating junction box (three-phase)

- Laser marking nameplate

- Independent welding leg

- Polished stainless steel finish

- 3-year warranty

Applications of Stainless Steel NEMA Motors

- Food and Beverage Industry

Stainless steel NEMA motors are widely used in the food and beverage industry due to their resistance to corrosion and ease of cleaning. These motors power equipment such as mixers, pumps, conveyors, and bottling machines, ensuring reliable operation in environments where sanitation and hygiene are critical. The corrosion-resistant nature of stainless steel makes these motors ideal for handling food-grade materials, while their washdown capabilities allow for thorough cleaning after every production cycle. - Pharmaceutical and Chemical Industries

In the pharmaceutical and chemical industries, where exposure to aggressive chemicals and frequent cleaning is a concern, stainless steel NEMA motors are invaluable. These motors are used in mixers, agitators, and pumps that handle sensitive or corrosive substances. The stainless steel construction ensures that the motor can withstand harsh environments and chemicals without deteriorating, while maintaining compliance with industry hygiene and safety standards. - Water and Wastewater Treatment

Stainless steel NEMA motors are essential in water and wastewater treatment plants. They are used in pumps, mixers, aerators, and filtration systems, where they are exposed to moisture, water, and often corrosive chemicals. The stainless steel casing provides protection against corrosion, ensuring long-term performance and reliability in harsh, wet environments. The motors’ durability allows them to perform consistently under challenging conditions, helping to maintain the efficiency of water treatment operations. - Marine and Offshore Applications

In marine and offshore environments, equipment is regularly exposed to saltwater and high humidity, which can lead to rapid corrosion of standard motors. Stainless steel NEMA motors are specially designed for such harsh conditions, offering superior resistance to corrosion and wear. These motors are used in pumps, winches, and other marine equipment, ensuring reliable operation in demanding environments like ships, offshore rigs, and coastal facilities. - Agricultural and Industrial Applications

Stainless steel NEMA motors are increasingly used in agricultural and industrial applications where the motor may be exposed to dirt, moisture, and corrosive elements. They are employed in grain handling systems, irrigation pumps, and agricultural machinery, where their rugged construction and resistance to corrosion provide extended service life and reliability. These motors are also found in industrial machinery such as conveyors and packaging lines, ensuring continuous operation in environments that require regular cleaning and maintenance.

Related Stainless Steel Motor

|

|

|

|

| Stainless steel permanent magnet motor | Water-cooled stainless steel motor | Food industry electric motor | Stainless steel motor |

|

|

|

|

| IEC emulsified food machinery AC motor | NEMA 56C asynchronous motor | IEC stainless steel AC motor | IEC all stainless steel high-efficiency motor |

|

|

|

|

| Chicken and duck depilation equipment motor | NEMA food-grade stainless steel motor | Food-grade IEC stainless steel motor |

About FMP

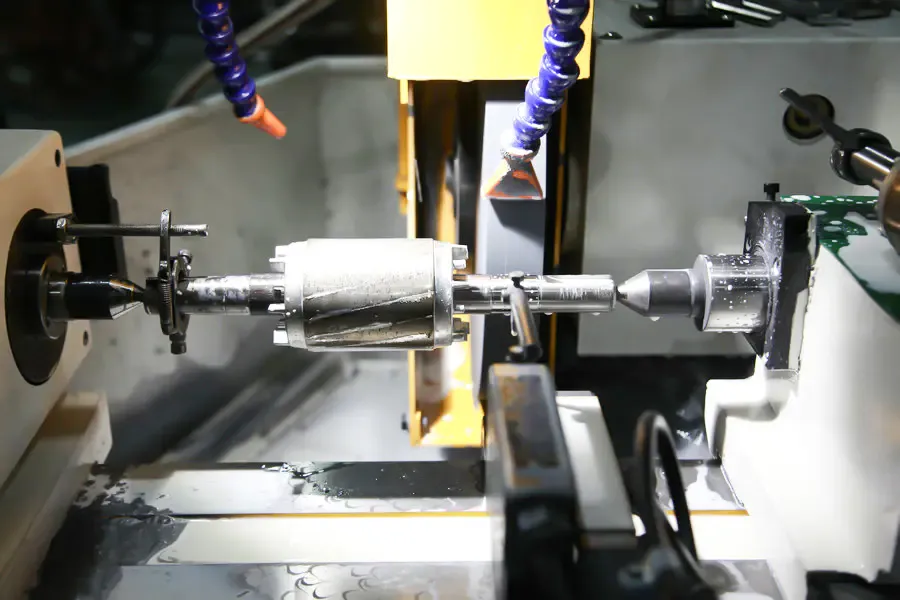

FMP is a national high-tech enterprise specializing in the design, development, and production of advanced motors and electromechanical solutions. We focus on producing YE2, YE3, and YE4 series motors, along with a range of derivative products. Our product offerings also include three-phase and single-phase motors for hydraulic pumps, aluminum-housing motors, non-standard motors for hydraulic pumps, electromechanical integration turbine gear reducers, and other specialized motors.

FMP’s products are extensively used in industrial automation, serving key sectors such as CNC lathes, shoemaking machinery, woodworking machinery, metalworking machinery, plastic machinery, and construction machinery. With a strong commitment to innovation and quality, FMP ensures that all products meet the highest performance standards.

In addition to our comprehensive product range, we are proud to offer custom solutions tailored to the specific needs of our clients. Whether you need specialized motors, non-standard products, or integrated systems, FMP works closely with clients to deliver high-quality, bespoke solutions. Our focus on precision engineering and client satisfaction drives our continued success in global markets.

At FMP, we are dedicated to building long-term, mutually beneficial partnerships, supporting the success of our clients with each project.

|

|

|

|

|

|

|

|

Author: CX