TEFC Stainless Steel NEMA Washdown Electric Motor

Over time, equipment downtime has become typical in food and beverage plants. Many indoor cabinets must be protected from excessive moisture from hose routing or splashing water (washdown). Washdown motors are designed for use in food and beverage plants and other applications where motors are frequently exposed to washdown and contaminants (chemicals, moisture, and humidity).

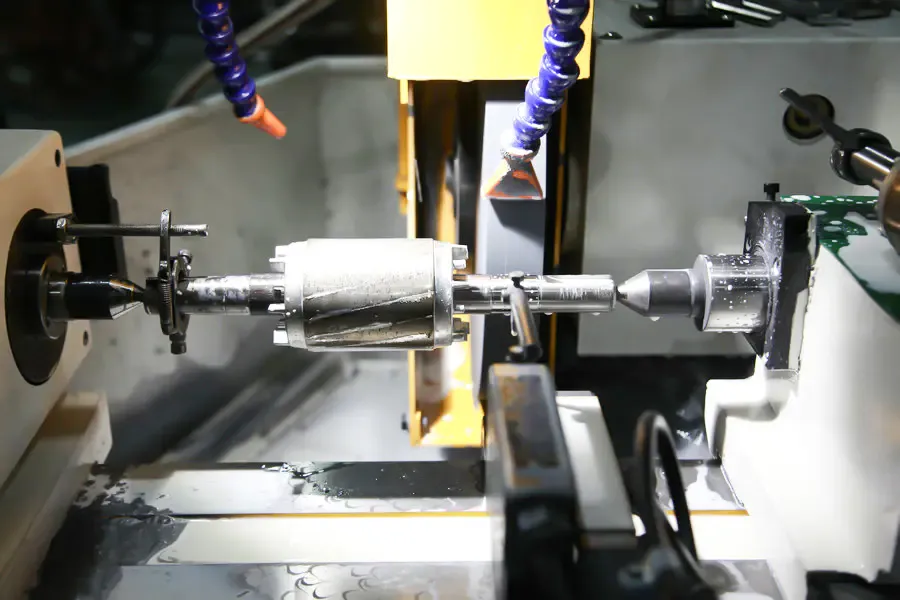

Washdown motors protect the motor’s internal components (stator windings, stator assembly, rotor, and shaft).

Washdown AC motors power conveyors in high humidity and humid environments. In chemical, pharmaceutical, food, and beverage production, regular washdown and cleaning of equipment is a necessity. They are fully enclosed and can withstand water or other fluids that could damage the motor’s internal components. The motor shaft features a V-ring rotating shaft seal and spring-loaded contact seals, while the motor bearings are lubricated with moisture-resistant grease for further washdown protection.

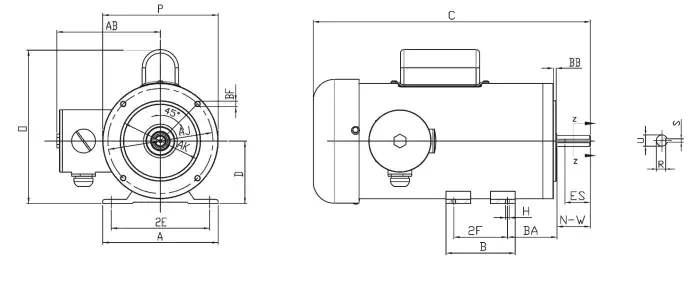

| Frame | A | BB | BA | N-W | U | R | S | ES | E | 2F | B | H | BF | AJ | P | AK | AB | D | 0 |

| 56C | 6.5 | 0.16 | 2.75 | 1.88 | 0.625 | 0.517 | 0.188 | 1.41 | 2.44 | 3 | 3.87 | 0.34 | 3/8-16 | 5.875 | 6.93 | 4.5 | 5.79 | 3.504 | 8.51 |

| 143TC | 6.5 | 0.16 | 2.75 | 2.25 | 0.771 | 0.771 | 0.188 | 1.41 | 2.75 | 4 | 4.87 | 4.87 | 3/8-16 | 5.875 | 6.93 | 4.5 | 5.79 | 3.504 | 8.51 |

| 145TC | 6.5 | 0.16 | 2.75 | 2.25 | 0.771 | 0.771 | 0.188 | 1.41 | 2.75 | 5 | 5.87 | 5.87 | 3/8-16 | 5.875 | 6.93 | 4.5 | 5.79 | 3.504 | 8.51 |

Applications of TEFC Stainless Steel NEMA Washdown Electric Motor

- Food Processing and Packaging

TEFC (Totally Enclosed Fan Cooled) stainless steel NEMA washdown motors are ideal for food processing plants where hygiene and cleanliness are paramount. These motors are designed to withstand high-pressure water and harsh cleaning chemicals typically used in food production environments. They are used in equipment like conveyors, mixers, pumps, and packaging machines, ensuring reliable performance while maintaining sanitary conditions. - Beverage Manufacturing

In the beverage industry, where contamination risks must be minimized, these motors provide an essential solution. TEFC stainless steel motors are used in bottling, capping, and labeling machines, as well as in filtration and pumping systems, offering corrosion resistance and easy maintenance in demanding washdown environments. - Chemical and Pharmaceutical Industries

The chemical and pharmaceutical sectors rely on these motors for applications requiring both durability and cleanliness. TEFC stainless steel motors are often used in mixing tanks, agitators, conveyors, and packaging lines, where exposure to corrosive materials and frequent cleaning cycles are common. The washdown capability ensures that motors can be safely cleaned without risking damage. - Water and Wastewater Treatment

In water and wastewater treatment plants, TEFC stainless steel motors are used in pumps, aerators, mixers, and filtration equipment. These motors provide the necessary protection against water and chemical exposure, ensuring uninterrupted performance in the often corrosive and high-moisture environments of water treatment facilities. - Marine and Offshore Applications

The stainless steel construction and TEFC design make these motors suitable for use in marine and offshore industries, where the motor is exposed to saltwater, high humidity, and harsh environmental conditions. These motors are commonly used in pumps, winches, and other equipment that require resistance to corrosion and easy washdown capabilities. - Cleaning Equipment

TEFC stainless steel motors are commonly found in commercial cleaning equipment such as pressure washers, floor scrubbers, and industrial vacuums. Their ability to withstand high-pressure washdowns and exposure to cleaning agents makes them ideal for maintaining cleanliness and reliability in cleaning machinery. - Packaging and Material Handling

In packaging and material handling systems, especially in industries such as pharmaceuticals, food, and chemicals, the washdown capability of these motors ensures long-lasting, trouble-free performance. They are used in conveyors, palletizers, and other automated systems that require frequent cleaning. - Agricultural Processing

These motors are also used in agricultural machinery where exposure to moisture, dust, and corrosive elements is frequent. Applications include grain handling systems, sorting machines, and irrigation systems, where the need for easy cleaning and corrosion resistance is essential.

By offering corrosion resistance, durability, and the ability to handle frequent cleaning, TEFC stainless steel NEMA washdown electric motors are crucial in industries where hygiene and operational reliability are non-negotiable.

Related Stainless Steel Motor

|

|

|

|

| Stainless steel permanent magnet motor | Water-cooled stainless steel motor | Food industry electric motor | Stainless steel motor |

|

|

|

|

| IEC emulsified food machinery AC motor | NEMA 56C asynchronous motor | IEC stainless steel AC motor | IEC all stainless steel high-efficiency motor |

|

|

|

|

| Chicken and duck depilation equipment motor | NEMA food-grade stainless steel motor | Food-grade IEC stainless steel motor |

About FMP

FMP is a national high-tech enterprise specializing in the design, development, and production of advanced motors and electromechanical solutions. We focus on producing YE2, YE3, and YE4 series motors, along with a range of derivative products. Our product offerings also include three-phase and single-phase motors for hydraulic pumps, aluminum-housing motors, non-standard motors for hydraulic pumps, electromechanical integration turbine gear reducers, and other specialized motors.

FMP’s products are extensively used in industrial automation, serving key sectors such as CNC lathes, shoemaking machinery, woodworking machinery, metalworking machinery, plastic machinery, and construction machinery. With a strong commitment to innovation and quality, FMP ensures that all products meet the highest performance standards.

In addition to our comprehensive product range, we are proud to offer custom solutions tailored to the specific needs of our clients. Whether you need specialized motors, non-standard products, or integrated systems, FMP works closely with clients to deliver high-quality, bespoke solutions. Our focus on precision engineering and client satisfaction drives our continued success in global markets.

At FMP, we are dedicated to building long-term, mutually beneficial partnerships, supporting the success of our clients with each project.

|

|

|

|

|

|

|

|

Author: CX