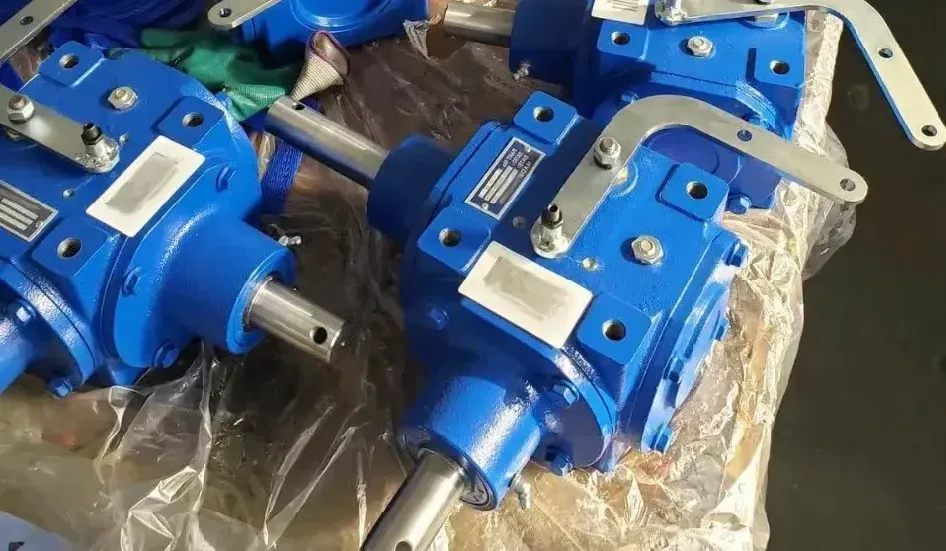

T Series Grain Storage Gearbox FMP-4090 Specifications

| Product Name | Grain storage gearbox |

| Material | A380 for housing, 40CrMnTi for gear shaft. |

| Color | Customized |

| Ratio | 1:35:1 |

| Rate power | 45HP |

| Weight | 13.2KG |

| Used | Grain storage |

Benefits of Using the T Series Grain Storage Gearbox for Agricultural

The T Series Grain Storage Gearbox offers numerous advantages for agricultural applications, particularly in grain storage systems. Here are the key benefits of using this gearbox:

1. Enhanced Durability and Reliability

- Long-lasting Performance: The T Series gearboxes are built with robust materials and precision engineering, ensuring they withstand the harsh conditions typical in agricultural environments. This durability leads to fewer breakdowns and longer service life, reducing maintenance costs and downtime.

2. High Efficiency

- Optimized Power Transmission: The gearboxes are designed to provide efficient power transmission, ensuring that the entire grain handling and storage system operates smoothly. This efficiency helps reduce energy consumption, lowering operational costs while maintaining optimal performance.

3. Customization Options

- Tailored to Specific Needs: The T Series can be customized to meet the specific demands of different grain storage applications. Whether for small-scale operations or large storage facilities, this gearbox can be adapted to suit a variety of configurations and system sizes.

4. Smooth Operation

- Noise and Vibration Reduction: The advanced design and construction of the T Series gearbox minimize operational noise and vibrations. This creates a quieter and more stable working environment, contributing to better overall system performance.

5. Improved Grain Handling

- Consistent Operation: With reliable power transmission and precision control, the T Series gearbox ensures consistent and even operation of grain handling equipment, such as conveyors and augers. This helps prevent damage to the grain and ensures that it is stored efficiently.

Using the T Series Grain Storage Gearbox in agricultural applications enhances efficiency, reduces operational costs, and extends the lifespan of equipment, all while maintaining high reliability and low maintenance requirements. These benefits make it an excellent choice for any modern grain storage facility, ensuring smoother operations and higher returns on investment.

|

|

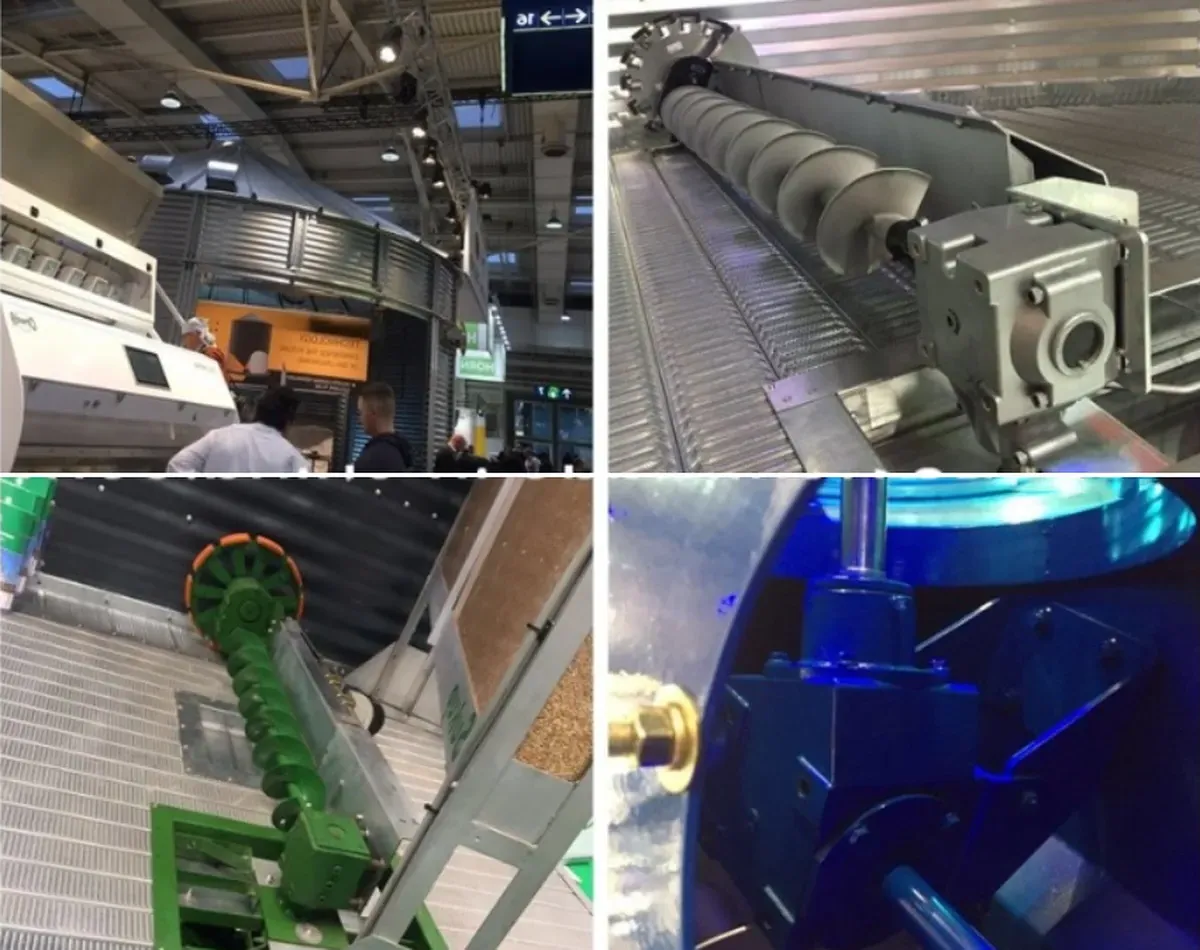

Applications of the T Series Grain Storage Gearbox for Agricultural

The T Series Grain Storage Gearbox is widely used in various agricultural applications, particularly those related to grain handling and storage. Its robust design and efficiency make it an essential component in many farming operations. Here are some of the key applications of the T Series Grain Storage Gearbox:

1. Grain Conveying Systems

- Role: The gearbox drives conveyors that transport grain from one location to another within storage facilities or between different stages of processing.

- Application: Used in bucket elevators, horizontal conveyors, and inclined conveyors, the T Series gearbox ensures smooth and efficient grain movement, reducing the risk of jams and delays.

2. Grain Augers

- Role: Augers are commonly used for loading and unloading grain from trucks or silos. The T Series gearbox powers the auger system, ensuring reliable and continuous grain flow.

- Application: The gearbox ensures consistent rotation and optimal control, preventing blockages and minimizing wear on the auger system, thus improving operational efficiency.

3. Grain Drying Systems

- Role: In grain dryers, the gearbox powers the rotating drum or conveyor systems that circulate grain for uniform drying.

- Application: By providing the necessary torque, the T Series gearbox ensures efficient and effective drying, crucial for maintaining grain quality and reducing moisture content.

4. Grain Storage Silo Operations

- Role: The T Series gearbox drives various mechanisms within grain silos, including aeration systems, unloading augers, and conveyors.

- Application: It ensures the smooth and reliable movement of grain in and out of silos, supporting better storage conditions and reducing the potential for spoilage due to poor aeration.

5. Grain Cleaning and Sorting Equipment

- Role: The gearbox is used to power the motors of cleaning and sorting machinery, such as vibratory screens, cleaners, and sorters, which are used to prepare grain for storage or sale.

- Application: With its efficient power transmission, the T Series gearbox ensures consistent performance of cleaning equipment, helping to remove impurities and ensuring only high-quality grain is stored or shipped.

The T Series Grain Storage Gearbox is an indispensable component in many agricultural processes, providing reliable and efficient power transmission for various grain handling, processing, and storage systems. Its versatility, efficiency, and durability make it ideal for grain conveying, drying, sorting, milling, and more, ensuring smooth operations across a wide range of agricultural applications.

About FMP

Headquartered in Italy, FMP is a premier manufacturer renowned for its expertise in designing, developing, and producing high-performance gearboxes, with a primary focus on the agricultural machinery sector. Known for our precision engineering, innovative solutions, and unwavering reliability, FMP has established itself as a trusted partner in both the agricultural and industrial markets. Our extensive portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide array of critical components, all crafted with meticulous attention to detail to meet the diverse needs of various applications.

At FMP, we recognize that every client faces unique challenges. This is why we specialize in providing tailored solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution not only meets their specific requirements but also enhances performance and maximizes value. Our commitment to delivering prompt, professional responses and expert guidance ensures that every inquiry is handled with precision, always leading to optimal outcomes.

Clear, continuous communication is at the core of our approach throughout the entire product development cycle. Our dedicated team collaborates directly with clients to gain a deep understanding of their needs, offering valuable insights and recommendations to achieve the best results. Whether we are designing cutting-edge products or fulfilling routine orders, FMP remains committed to delivering high-quality, precision-engineered solutions on time, every time. Our mission is to consistently exceed client expectations by providing exceptional service and outstanding results with every project.

Quality is central to all that we do at FMP. We adhere to the highest manufacturing standards and enforce rigorous quality control measures to ensure each product not only meets but often surpasses industry benchmarks. This commitment to excellence, along with our core values of integrity, teamwork, and perseverance, has allowed us to build long-term, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is always eager to foster global partnerships, offering expert advice and customized solutions to meet the evolving needs of our clients. We are dedicated to building long-term, mutually beneficial relationships that drive the success of every project. Whether you are seeking innovative solutions for a new venture or require ongoing support for an existing system, FMP is here to assist in overcoming technical challenges and ensuring your continued success.

Author: CX