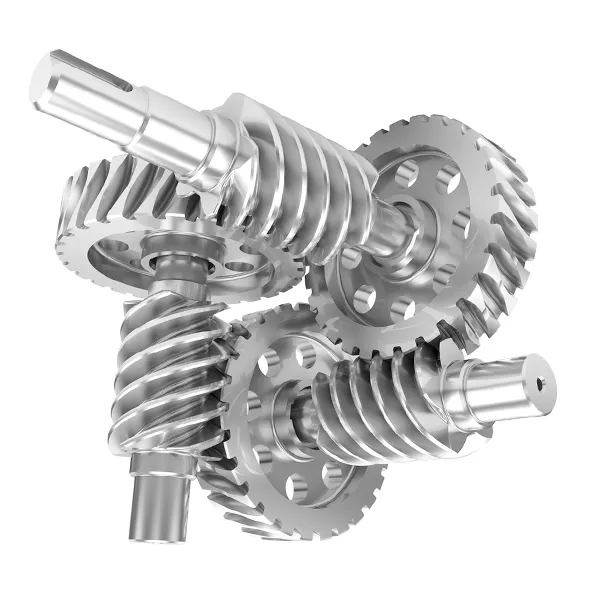

At FMP Company, we specialize in manufacturing a wide range of Stainless Steel Worm Gears designed to meet diverse industrial needs. In addition to our extensive catalog, we also offer custom solutions tailored to your specific requirements. If you don’t find the exact model you’re looking for in our product list, it’s likely we haven’t had the chance to update it yet. Please feel free to email us with details of the model you need, and our engineers will respond within 24 hours to assist you.

Product Parameters

| Product name | Worm Gear and Worm Wheel |

| Materials Available | Stainless Steel, Carbon Steel, Brass, Bronze, Iron, Aluminum Alloy,Copper,Plastic,Nylon,PA66,MC,PEER,MSM,POM,Derlin etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Surface Treatment | Carburizing and Quenching, Tempering ,Tooth surface high quenching Hardening, Tempering |

| BORE | Finished bore, Pilot Bore, Special request |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding, etc |

| Pressure Angle | 20 Degree |

| Hardness | 55- 60HRC |

| Size | Customer Drawings & ISO standard |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001:2008 |

| Applications | Electric machinery, metallurgical machinery, environmental protection machinery, electronic and electrical appliances, road construction machinery, chemical machinery, food machinery, light industrial machinery, mining machinery, transportation machinery, construction machinery, building materials machinery, cement machinery, rubber machinery, water conservancy machinery and petroleum machinery |

| Machining Process | Material preparation, normalizing, rough turning, quenching and tempering, semi-fine turning outer circle, rough turning spiral surface, fine turning (fine grinding) inner hole end face, keyway, semi-fine turning spiral surface, pliers (rest incomplete teeth), semi-fine grinding outer circle, semi-fine grinding spiral surface, grinding center hole, delicate grinding outer ring, fine scratching helical surface, finished product inspection. |

| Advantages | 1. Produce strictly following ANSI or DIN standard dimension 2. Material: SCM 415 steel 3. Bore: Finished bore 4. Precision grade: DIN 5 to DIN 7 5. Surface treatment: Carburizing and Quenching 6. Module: From 1 to 4 7. Tooth: From Z15 to Z70 |

Specification:

| Number | Number of Teeth | Shaft Bore Dia. AH7 (1mm Increment) | Twisting Direction | B | C | D | E | F | G | ||

| Type | Module | Straight Bore Straight Bore+Tap | Keyway+Tap | ||||||||

| Straight Bore

Straight Bore+Tap Keyway+Tap |

1.0 | 20 | 6 | 8 | L(Left)

R(Right) |

17 | 20 | 22 | 8 | 10 | 18 |

| 22~ 28 | 8 | 8~13 | 18~20 | 22~28 | 24~30 | ||||||

| 30~48 | 10 | 10~17 | 25~30 | 30~48 | 32~50 | ||||||

| 50~70 | 12 | 12~17 | 35~40 | 50~70 | 52~72 | ||||||

| 80~100 | 15 | 15~30 | 50 | 80~100 | 82~102 | ||||||

| 1.5 | 20~26 | 12 | 12~17 | 24~32 | 30~39 | 33~42 | 12 | 12 | 24 | ||

| 28~44 | 15 | 15~30 | 36~50 | 42~67.5 | 45~70.5 | ||||||

| 45~52 | 18 | 18~40 | 50~60 | 72~78 | 75~81 | ||||||

| 60~100 | 20 | 20-50 | 60~70 | 90~150 | 93·153 | ||||||

| 2.0 | 15~18 | 12 | 12~17 | 24~30 | 30~36 | 34~40 | 16 | 13 | 29 | ||

| 20~28 | 15 | 15·22 | 32~45 | 40~56 | 44~60 | ||||||

| 30~36 | 18 | 18~40 | 50 | 60~72 | 64~76 | ||||||

| 40~48 | 20 | 20~44 | 60 | 80~96 | 84~100 | ||||||

| 50~100 | 25 | 25~60 | 60~100 | 100~200 | 104~204 | ||||||

| 2.5 | 15~18 | 15 | 15~30 | 30~38 | 37.5~45 | 42.5~50 | 20 | 14 | 34 | ||

| 20~24 | 18 | 18~40 | 40~48 | 50~60 | 55~65 | ||||||

| 25~36 | 20 | 20~50 | 50~70 | 62.5~90 | 67.5~95 | ||||||

| 40~60 | 25 | 25~70 | 70~80 | 90~150 | 95~155 | ||||||

| 3.0 | 15~18 | 18 | 18~22 | 36~40 | 45~54 | 51~60 | 25 | 16 | 4 | ||

Related Product

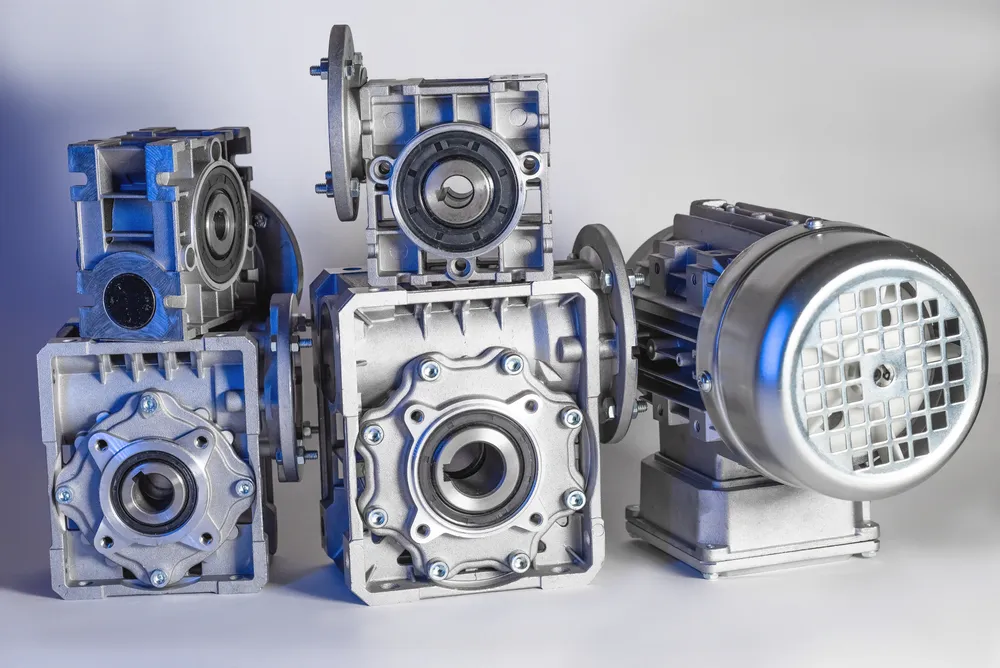

We’d like to highlight that FMP Company also proudly manufactures Stainless Steel Worm Gearboxes, specifically engineered to meet the stringent demands of the food industry. These gearboxes are crafted with precision, ensuring durability, corrosion resistance, and compliance with hygiene standards, making them an ideal choice for food processing applications. If you have any requirements or inquiries about our Stainless Steel Worm Gearboxes, please don’t hesitate to reach out to us. Our dedicated team is ready to assist you promptly, providing tailored solutions to enhance your operations. Contact us today to discuss your needs!