Stainless Steel Rings: Powering Wind Turbines

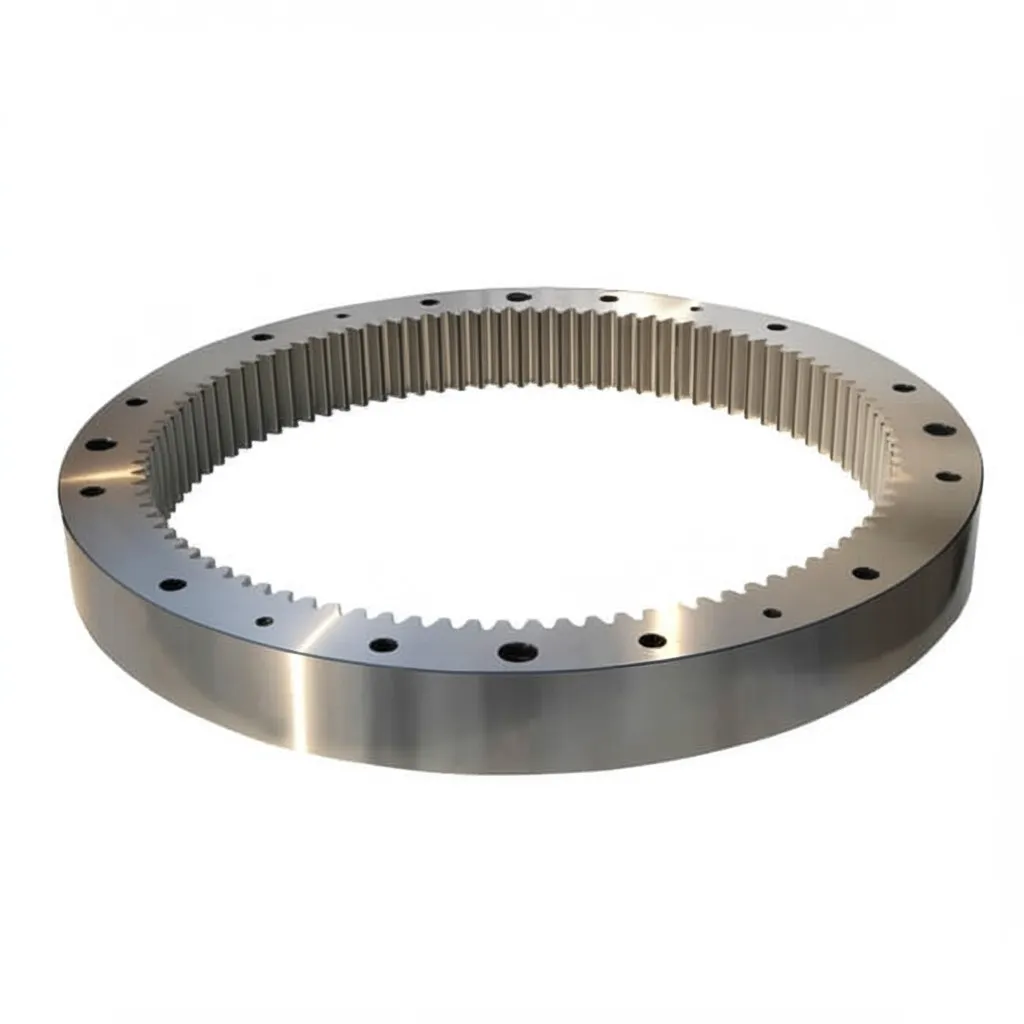

Stainless steel rings are critical components in modern engineering, prized for their exceptional corrosion resistance, wear durability, and rust-proof properties. In wind turbines, these rings—often designed as internal ring gears—play a vital role in the yaw and pitch systems, ensuring precise movement and long-term reliability under harsh environmental conditions. Italy, with its growing renewable energy sector in cities like Milan and Bologna, relies on such high-precision components to support sustainable power generation. Made from premium stainless steel, these rings excel in demanding applications, from heavy machinery to maritime equipment in Venice and aerospace innovations in Florence, making them indispensable for industrial excellence.

|

Specifications

|

|

Shape

|

|

|

Tooth Profile

|

involute |

|

Description

|

Transmission Ring Gear

|

|

Size

|

According to Drawing

|

|

|

Carbon Steel

|

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214L etc

|

|

Alloy Steel

|

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5 etc

|

|

Brass/Bronze

|

HPb59-1, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40 etc

|

|

|

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc

|

|

|

Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,

Gear Shaving, Gear Grinding, and Gear Lapping

|

|

|

Outer Diameter

|

±0.005 mm

|

|

Length Dimension

|

±0.05 mm

|

|

|

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding……

|

|

|

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0

|

|

|

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating……

|

| Gear Basic Data |

| Gear Tooth Shape |

involute |

| Gear Material |

42CrMo |

| Gear Process |

fogging, lasting, tooth milling, internal and plane grinding, tooth grinding |

| Pressure Angle |

20° |

| Quality level |

DIN 3962 class 7 |

| Gear Type |

Mn=6, Z=109, β=0°, X=-0.25 |

CAPABILITIES OF GEAR/ SPLINE

| INTERNAL GEARS AND INTERNAL SPLINES |

|

MILLING |

SHAPING |

TOOTH GRINDING |

| Maximum O.D. |

2500 mm |

2500 mm |

2500 mm |

| Minimum I.D. |

650 mm |

50 mm |

100 mm |

| Maximum Face Width |

500 mm |

500 mm |

500 mm |

| Maximum Diametral Pitch |

DP 1 |

DP 1 |

DP 0.5 |

| Maximum Module |

26 mm |

26 mm |

45 mm |

| AGMA Level/ DIN Level |

DIN Class 8 |

DIN Class 8 |

DIN Class 4 |

| Tooth Surface Finishing |

Ra 3.2 |

Ra 3.2 |

Ra 0.6 |

| Maximum Helix Angle |

±22.5° |

±22.5° |

±45° |

| EXTERNAL GEARS AND EXTERNAL SPLINES |

|

HOBBING |

MILLING |

TOOTH GRINDING |

| Maximum O.D. |

1250 mm |

2500 mm |

2500 mm |

| Minimum O.D. |

20 mm |

200 mm |

20 mm |

| Maximum Face Width |

500 mm |

500 mm |

1480 mm |

| Maximum Diametral Pitch |

DP 1 |

DP 1 |

DP 0.5 |

| Maximum Module |

26 mm |

26 mm |

45 mm |

| AGMA Level/ DIN Level |

DIN Class 8 |

DIN Class 8 |

DIN Class 4 |

| Tooth Surface Finishing |

Ra 3.2 |

Ra 3.2 |

Ra 0.6 |

| Maximum Helix Angle |

±45° |

±45° |

±45° |

FMP: Your Source for Premium Stainless Steel Ring Gears

FMP is a leading manufacturer, exporter, and supplier of high-quality heavy machinery components, including a diverse range of ring gears crafted from stainless steel. Based in Italy, we serve industries across Milan, Venice, Florence, and Bologna, delivering robust, wear-resistant products with durable surface treatments that minimize pitting and maximize longevity—all at competitive costs. Our expertise spans custom solutions for sugar mill gears, mechanical ring gears, and specialized stainless steel rings for wind turbines. Whether you’re powering renewable energy projects in Bologna or maritime systems in Venice, FMP offers tailored designs to meet your exact specifications, ensuring top performance and structural integrity.

Custom Orders and Fast Support from FMP

Can’t find the stainless steel ring model you need for your wind turbine or other application? At FMP, we produce a wide variety of ring gears and welcome custom orders to suit your unique requirements. If your desired model isn’t listed, it’s likely we haven’t uploaded it yet—simply email us your specifications, and our expert engineers will reply within 24 hours with a solution. Serving Italy’s industrial hubs like Milan, Florence, Venice, and Bologna, we’re committed to supporting your projects with precision and speed. Contact FMP today to enhance your wind turbine systems with our elite stainless steel ring gears!