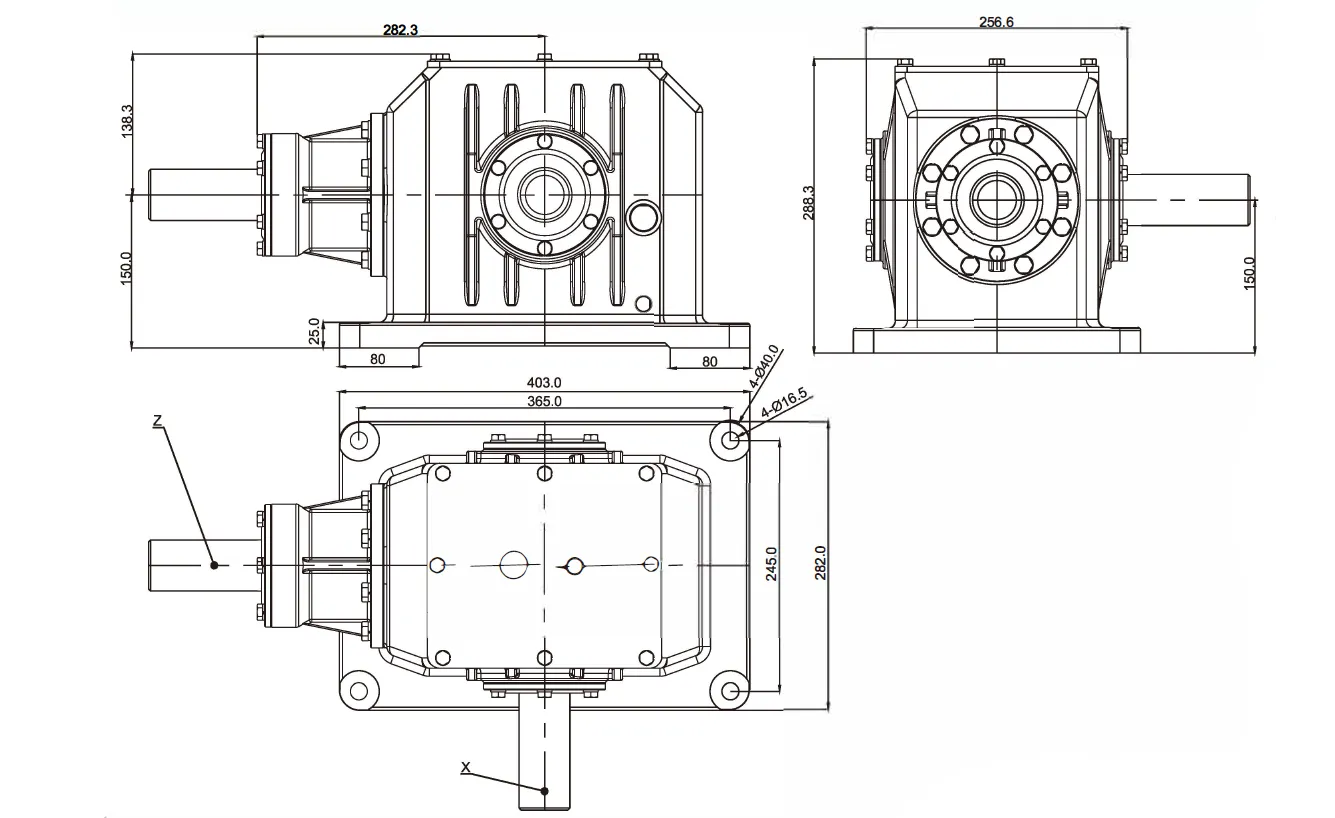

Square Baler Gearbox FMP-FK150 Dimensions

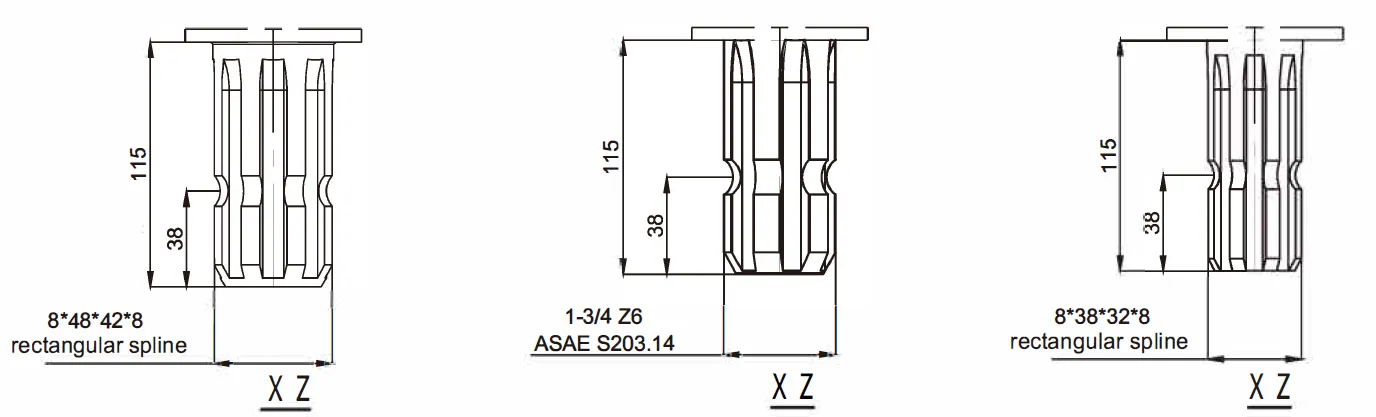

Square Baler Gearbox FMP-FK150 Shaft Dimensions

Square Baler Gearbox FMP-FK150 Technical Data

| i | Suitable | Rpm input | Rpm output | KW(Nom) | KW(Max) | Toothing | |

| r/min | r/min | hp | hp | ||||

| Speed increase | 1:2.07 | Square Baler, etc | 540 | 1117.8 | 120 | 550 | Gleason Straight Teeth |

| Remark: If you have any special require feel free let me know, we also accept custom. | |||||||

The Square Baler Gearbox FMP-FK150 is specifically designed to meet the demanding requirements of agricultural baling machinery, particularly for creating square bales in hay, straw, silage, and other crops. Its design integrates advanced engineering features to provide reliable performance, durability, and ease of operation. Below are the key design features of the FMP-FK150 Square Baler Gearbox:

High Torque Capacity

- Feature: The FMP-FK150 gearbox is engineered to handle high torque levels, making it suitable for demanding agricultural tasks like baling. Its robust internal components are designed to withstand the heavy forces exerted during the baling process.

- Benefit: Ensures smooth, efficient operation even under load, allowing the baler to form dense, uniform bales without risk of performance issues or component failure.

Precision Gear Design

- Feature: The gears inside the FMP-FK150 gearbox are designed with precision to ensure smooth meshing and minimal wear. The high-quality gears optimize power transmission efficiency.

- Benefit: This reduces energy loss, making the baling process more efficient, and increases the lifespan of the gearbox by reducing wear and tear on the internal components.

Heavy-Duty Housing

- Feature: The gearbox is housed in a strong, durable casing made from high-quality materials such as cast iron or reinforced alloys.

- Benefit: The robust housing protects the internal gears from external impacts and harsh agricultural environments, ensuring long-term durability and reliability.

Efficient Lubrication System

- Feature: The FMP-FK150 is designed with an efficient lubrication system that ensures even distribution of lubricant to all moving parts. This system helps maintain optimal operating temperatures and minimizes friction.

- Benefit: The enhanced lubrication system reduces wear on gears, lowers the risk of overheating, and extends the lifespan of the gearbox, even during extended operations.

The Square Baler Gearbox FMP-FK150 is designed with advanced features that ensure high efficiency, durability, and ease of use in demanding agricultural environments. Its high torque capacity, precision engineering, and durable housing make it a reliable choice for forming consistent, high-quality square bales. The versatile, compact design ensures compatibility with a wide range of balers and farming equipment, while its focus on reliability and low maintenance helps to reduce operational costs and increase productivity. Whether used in hay, straw, silage, or other applications, the FMP-FK150 gearbox is a critical component for modern agricultural operations.

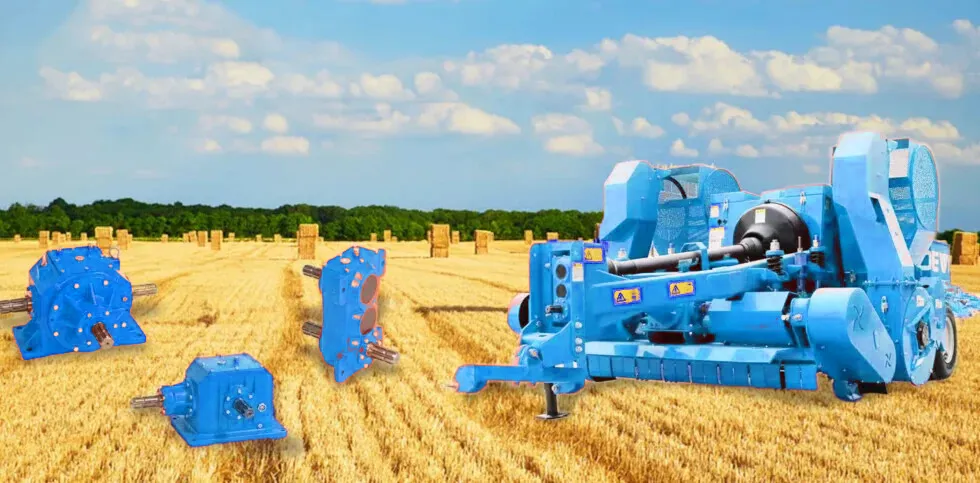

Application Areas of Square Baler Gearbox FMP-FK150

The Square Baler Gearbox FMP-FK150 is specifically designed for use in various agricultural applications, particularly in baling systems. Its robust and high-performance design makes it suitable for a wide range of agricultural machinery and operations. Below are the key application areas where the FMP-FK150 gearbox excels:

Hay Baling

- Application: The FMP-FK150 gearbox is extensively used in hay balers to create square bales of dried grass or hay, a critical component in livestock feed production.

- Benefit: The gearbox ensures efficient power transmission to the baling mechanisms, resulting in well-formed, tightly packed square hay bales that are easy to store and transport.

Straw Baling

- Application: Straw, a byproduct of crops such as wheat, barley, and oats, is often baled for use as bedding material for animals, or for composting and bioenergy production. The FMP-FK150 gearbox is ideal for this application.

- Benefit: Its high torque capacity and reliable performance ensure that the baler works effectively even with dense or tough straw, producing strong, uniform bales.

Silage Baling

- Application: In silage production, crops such as grass, corn, or legumes are baled for storage in an anaerobic environment to maintain their nutritional value. The FMP-FK150 gearbox can be used in silage balers to form compact, sealed square bales.

- Benefit: The gearbox provides the necessary torque for compressing moist, heavy silage, ensuring high-density bales that are easy to store and preserve.

Crop Residue Baling

- Application: After harvesting, crop residues like corn stalks, cotton stalks, and other plant materials are often baled for use in bioenergy production or as feedstock for various agricultural processes.

- Benefit: The gearbox handles the high demands of baling tough, fibrous crop residues, ensuring that bales are tightly packed and suitable for further processing or use.

The Square Baler Gearbox FMP-FK150 is ideal for a wide range of agricultural applications where high-density square bales are required. Whether for hay, straw, silage, or crop residues, the gearbox ensures reliable, efficient performance, maximizing the operational efficiency of baling machinery. Its versatility, high torque capacity, and durability make it a valuable component for agricultural operations, whether on small family farms or large commercial enterprises.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a particular focus on the agricultural machinery sector. With a reputation for precision engineering, innovative solutions, and unwavering reliability, FMP has become a trusted partner in addressing the evolving needs of both the agricultural and industrial sectors. Our diverse product range includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all meticulously engineered to provide customized solutions across a broad spectrum of applications.

At FMP, we understand that each client has unique requirements and challenges. This is why we specialize in offering tailored solutions, whether for individual components or fully integrated systems. We work in close collaboration with our customers to ensure that every solution is not only effective but also efficient, optimizing both performance and value. Our commitment to providing quick, professional responses, coupled with expert guidance, ensures that every inquiry is treated with the utmost care and precision, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development process. Our dedicated team works directly with clients to fully understand their specific needs, offering valuable insights and recommendations to ensure optimal solutions. Whether designing innovative products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to provide clients with the best service and results, exceeding expectations with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control measures to ensure that each product not only meets but exceeds industry standards. This unwavering commitment to quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to build long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond just supplying products; we aim to build enduring relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to tackle your technical challenges and ensure your continued success.

Author: CX