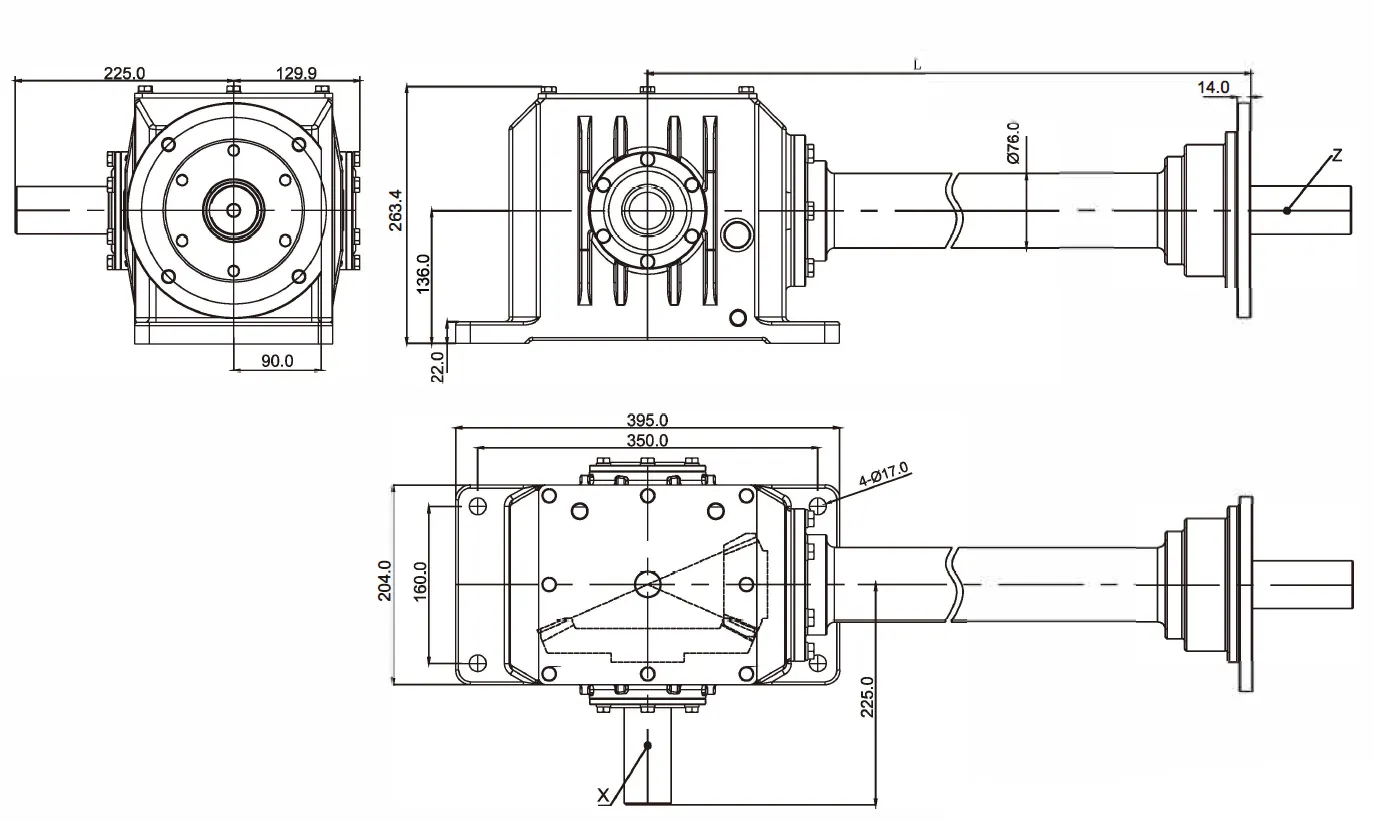

Square Baler Gearbox FMP-FK136 Dimensions

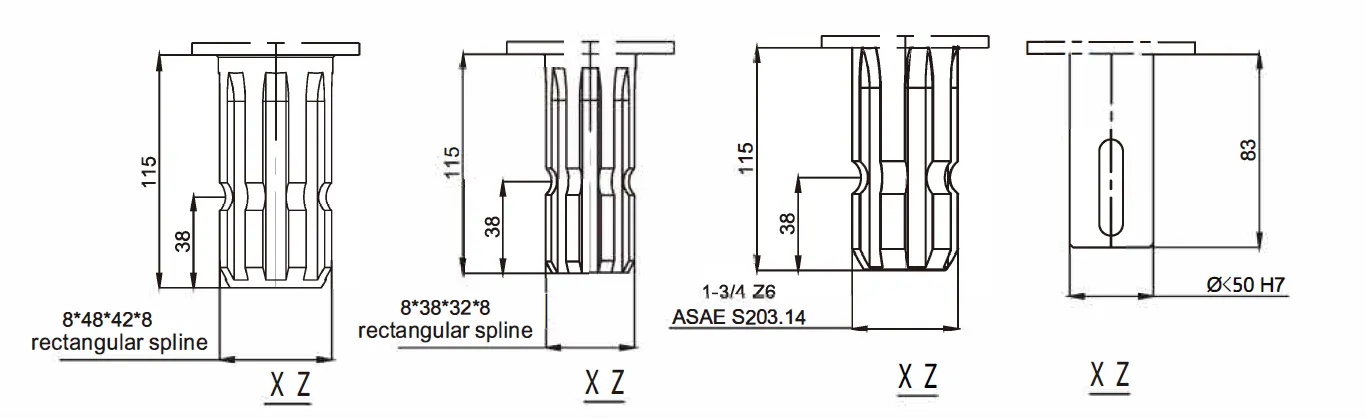

Square Baler Gearbox FMP-FK136 Shaft Dimensions

Square Baler Gearbox FMP-FK270 Technical Data

| i | Suitable | Rpm input | Rpm output | KW(Nom) | KW(Max) | Toothing | |

| r/min | r/min | hp | hp | ||||

| Speed increase | 1:2.28 | Square Baler, etc | 540 | 1231.2 | 140 | 500 | Gleason Straight Teeth |

| Remark: If you have any special require feel free let me know, we also accept custom. | |||||||

Square Baler Gearbox FMP-FK136 Structure Components

The Square Baler Gearbox FMP-FK136 is a robust and precision-engineered gearbox designed to handle the high-torque demands of square baling machinery. Its structural components are designed to ensure efficient power transmission, durability, and smooth operation, even under harsh agricultural conditions. Below are the key structural components of the FMP-FK136 Square Baler Gearbox:

1. Input Shaft

- Function: The input shaft is the component that connects the gearbox to the tractor’s PTO (Power Take-Off) system. It transfers the rotational power from the tractor to the gearbox.

- Material: Typically made of high-strength steel, the input shaft is designed to withstand the torque transmitted from the tractor.

2. Main Housing

- Function: The main housing is the outer casing that encloses all the internal gears and components of the gearbox. It protects the internal components from dirt, debris, and environmental stress, while also housing the lubrication system.

- Material: Constructed from durable, high-strength cast iron or steel, the housing is designed to resist impact and wear.

3. Planetary Gear Set

- Function: The planetary gear set is a key component in many gearboxes, including the FMP-FK136. It consists of the sun gear, planet gears, and the ring gear, which work together to provide the required reduction ratio for smooth power transmission.

- Material: Precision-machined and heat-treated to ensure minimal wear and long-lasting performance, the gears are typically made from hardened steel.

4. Bevel Gears

- Function: Bevel gears are used to change the direction of rotation within the gearbox. These gears are particularly important when the input shaft drives the gearbox at an angle, transferring power to different components of the baler.

- Material: Bevel gears are made of high-strength, heat-treated steel, ensuring that they can withstand high loads and continue to operate smoothly.

5. Output Shaft

- Function: The output shaft is where the power from the gearbox is transmitted to the square baler’s operational components, such as the feeding system, knotter mechanism, and compression chamber. The output shaft is designed to provide the correct speed and torque to operate these components effectively.

- Material: Like the input shaft, the output shaft is made from high-strength steel to ensure durability and longevity.

The Square Baler Gearbox FMP-FK136 consists of several precision-engineered components designed to work together seamlessly, ensuring reliable power transmission and efficient operation in agricultural baling equipment. From the high-strength input and output shafts to the planetary gear sets, bearings, and seals, each component is crafted for durability and long-term performance. The robust design and strategic component arrangement ensure that the gearbox can handle high torque and demanding agricultural conditions, making it a trusted part of modern baling machinery.

Square Baler Gearbox FMP-FK136 Common Applications

The Square Baler Gearbox FMP-FK136 is specifically designed for use in agricultural machinery, primarily in the baling process. Its robust construction and efficient power transmission make it suitable for various baling applications where high torque, durability, and precision are required. Below are some of the common applications of the FMP-FK136 Square Baler Gearbox:

Hay Baling

- Application: The FMP-FK136 gearbox is commonly used in hay baling operations, where hay is gathered, compressed, and bound into rectangular bales for storage and transportation. The gearbox efficiently transmits power from the tractor’s PTO (Power Take-Off) to the baler’s internal mechanisms.

- Benefits: The gearbox ensures consistent bale formation, even with varying moisture content and density of hay, while maintaining optimal performance over long operational hours.

Straw Baling

- Application: The FMP-FK136 gearbox is widely employed in straw baling, especially after cereal crops like wheat or barley are harvested. It helps in compacting the straw into square bales, making it easier to store, transport, and use for various purposes like bedding or biomass fuel.

- Benefits: Its strong and efficient power transmission ensures that even dense and fibrous straw is baled properly, preventing clogging and reducing wear on the baler.

Silage Baling

- Application: Used in silage baling, the FMP-FK136 gearbox helps bale wet, green forage crops like alfalfa or corn silage, which are fermented and used as animal feed. These materials require special handling due to their high moisture content, and the gearbox is built to perform reliably under such conditions.

- Benefits: The gearbox’s smooth and efficient operation ensures tight bales even in moist, challenging conditions, and helps preserve the nutritional quality of the silage.

Alfalfa Baling

- Application: Alfalfa baling is another key application for the FMP-FK136 gearbox. Alfalfa is a high-protein forage crop that is baled for livestock feed. The gearbox is used to power the baling process, ensuring the crop is compressed into well-formed, dense bales.

- Benefits: The gearbox ensures uniform bale density and proper compression, which is essential for preserving the quality and nutritional value of alfalfa hay.

Crop Residue Baling

- Application: The FMP-FK136 gearbox is used in crop residue baling, where leftover materials such as corn stalks, wheat straw, and other plant matter are baled after the primary crop has been harvested. These residues can be repurposed for various uses, including bioenergy production, livestock bedding, and composting.

- Benefits: Its ability to handle a variety of materials and consistently produce compact bales makes it ideal for this application, which helps reduce field waste and improve farm efficiency.

The Square Baler Gearbox FMP-FK136 is a key component in various agricultural baling applications, particularly where high torque and durability are essential. Its ability to perform in diverse conditions—from hay and straw baling to biomass and silage—makes it a highly versatile and reliable gearbox for modern farming and agricultural operations. Whether used for small-scale or large-scale farming, the FMP-FK136 gearbox plays a critical role in ensuring efficient and high-quality bales for various purposes.

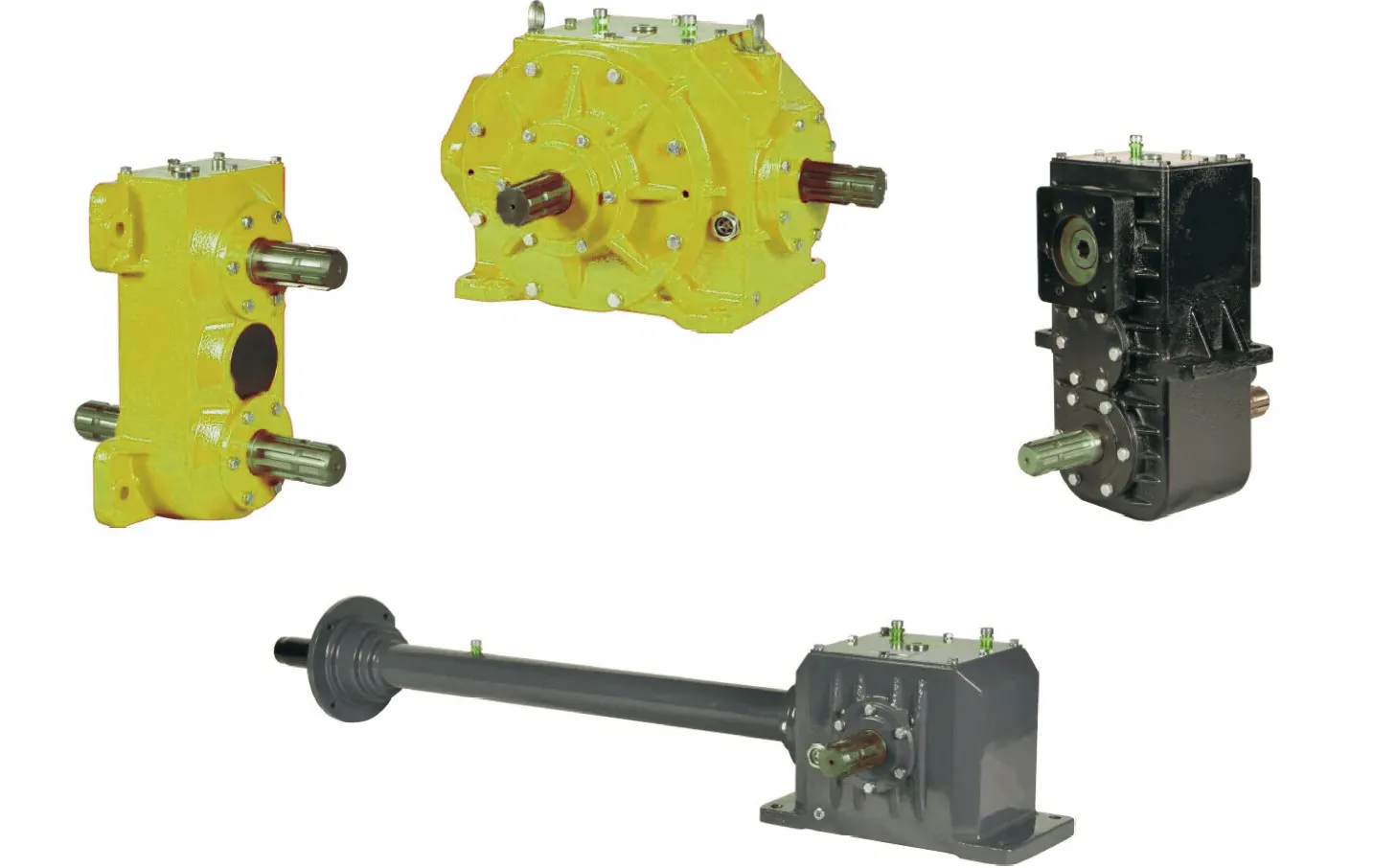

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in designing, developing, and producing high-performance gearboxes, with a strong emphasis on the agricultural machinery sector. Known for its precision engineering, innovative solutions, and unwavering reliability, FMP has established itself as a trusted partner for addressing the evolving needs of both the agricultural and industrial markets. Our comprehensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other critical components, all meticulously engineered to deliver tailored solutions across a wide range of applications.

At FMP, we recognize that each client faces unique challenges. That’s why we specialize in providing custom solutions, whether for individual components or fully integrated systems. We collaborate closely with our clients to ensure every solution is not only effective but also efficient, optimizing performance and delivering maximum value. Our dedication to offering swift, professional responses, combined with expert guidance, ensures that each inquiry is handled with precision and care, leading to the best possible outcomes.

We prioritize open and continuous communication throughout the entire product development lifecycle. Our dedicated team works directly with clients to gain a deep understanding of their specific requirements, offering valuable insights and recommendations to ensure the most effective solutions. Whether designing new products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our goal is to consistently exceed expectations and provide clients with the best service and results in every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards, implementing rigorous quality control processes to ensure that every product not only meets but surpasses industry requirements. This steadfast commitment to quality, coupled with our core values of integrity, teamwork, and perseverance, has enabled us to build long-term, trust-based relationships with clients in over 30 countries around the world.

FMP is always eager to foster global partnerships and remains dedicated to offering expert advice and customized solutions that meet the diverse needs of our clients. We go beyond simply providing products; we aim to cultivate enduring relationships that contribute to the success of every project. Whether you’re seeking innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to address your technical challenges and ensure your continued success.

Author: CX