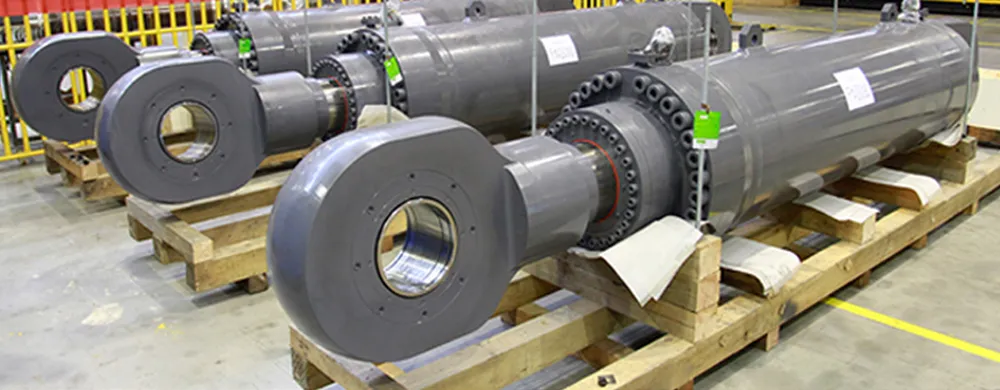

Split Barge Split Cylinder

The Split Barge Split Cylinder is a specialized hydraulic component engineered to enhance the functionality and efficiency of split barges in marine operations. This cylinder is designed to provide the necessary force for the separation of barge sections, facilitating easy loading and unloading of cargo while improving the vessel’s maneuverability.

Key Features:

- High Force Output: Capable of generating substantial hydraulic force, this cylinder ensures smooth and efficient splitting of barge sections, optimizing cargo handling operations.

- Robust Construction: Made from high-strength materials, it is designed to withstand the harsh marine environment, ensuring durability and reliability even under extreme conditions.

- Precise Control: The advanced hydraulic design allows for accurate and controlled movements, enhancing safety during operation and minimizing the risk of accidents.

- Versatile Application: Ideal for various marine logistics and transportation scenarios, this split cylinder supports efficient operations in both loading and unloading processes.

- Low Maintenance Requirements: Engineered for minimal wear and tear, the cylinder requires less maintenance, reducing downtime and contributing to increased operational efficiency.

The Split Barge Split Cylinder is an essential component for optimizing the performance of split barges, significantly improving the efficiency and safety of marine logistics and transportation operations.

Split Barge Split Cylinder Specifications:

| Product Name | Split Barge Split Cylinder |

| Features: | Closed hull |

| Bore diameter: | Up to 550mm |

| Rod diameter: | Up to 280mm Stroke≤1000mm |

| Pull force: | Up to 6000KN |

| Pressure: | Up to 38MPa |

| Applications: | Split Barge |

Features of Split Barge Split Cylinder

- High Force Output:

- Capable of generating substantial hydraulic force for efficient separation of barge sections, ensuring smooth operation during loading and unloading.

- Robust Construction:

- Constructed from high-strength materials designed to withstand harsh marine environments, providing durability and reliability in extreme conditions.

- Precise Control:

- Advanced hydraulic design enables accurate and controlled movements, enhancing safety and minimizing the risk of operational accidents.

- Versatile Application:

- Suitable for various marine logistics scenarios, facilitating efficient cargo handling in diverse loading and unloading processes.

- Low Maintenance Requirements:

- Engineered for minimal wear and tear, this cylinder requires less maintenance, reducing downtime and increasing overall operational efficiency.

- Corrosion Resistance:

- Treated or coated to resist corrosion from saltwater and other marine elements, ensuring longevity and reliable performance.

- Compact Design:

- Space-efficient design allows for easy integration into existing barge systems without compromising structural integrity.

- Safety Features:

- Equipped with built-in safety mechanisms to prevent accidental activation or failure, enhancing operational reliability.

- Easy Installation:

- Designed for straightforward installation and replacement, minimizing downtime during maintenance or upgrades.

- Enhanced Maneuverability:

- Improves the maneuverability of split barges, allowing for better navigation and handling in crowded or challenging marine environments.

These features make the Split Barge Split Cylinder an essential component for optimizing the efficiency and safety of marine logistics and transportation operations.

Applications of Split Barge Split Cylinder

- Marine Logistics:

- Used in the loading and unloading of cargo in split barges, enhancing operational efficiency in transporting goods over water.

- Cargo Handling:

- Facilitates the separation of barge sections to enable easy access to cargo holds, improving the speed and safety of cargo operations.

- Dredging Operations:

- Employed in dredging applications where split barges are used to transport dredged materials, allowing for efficient management of sediment removal.

- Maintenance and Repairs:

- Assists in the maintenance of split barges by enabling access to internal components for inspection and repair, enhancing overall vessel upkeep.

- Construction Projects:

- Utilized in construction-related marine activities where split barges are required to transport heavy materials and equipment to construction sites.

- Environmental Cleanup:

- Supports operations in environmental remediation projects where split barges are used to transport waste materials or equipment for cleanup efforts.

- Offshore Operations:

- Applied in offshore drilling and exploration activities, where split barges can be used to transport equipment and personnel efficiently.

- Shipbuilding and Repair Yards:

- Used in shipyards for the transportation of materials and components necessary for building or repairing ships, facilitating efficient logistics.

- Emergency Response:

- Assists in rapid deployment of resources during maritime emergencies, allowing for quick access to essential equipment and supplies.

- Ferry Services:

- Enhances the functionality of split ferry barges, improving the efficiency of transporting vehicles and passengers across water.

These applications demonstrate the versatility and importance of the Split Barge Split Cylinder in various marine and logistical operations, contributing to enhanced efficiency and safety in the maritime industry.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX