Spindle Motor Applications

Spindle motors are essential in various precision machining and manufacturing processes, driving the rotation of tools and enabling high-performance cutting, grinding, and milling operations. Commonly used in CNC machines, they offer high torque and speed control, making them ideal for applications that require tight tolerances and complex geometries. Their ability to provide consistent power output ensures optimal cutting performance and surface finish quality.

In the automotive and aerospace industries, spindle motors are employed in high-precision manufacturing, such as engine parts, turbine blades, and other critical components. Their versatility allows them to handle a wide range of materials, from metals to composites, while maintaining the high-quality standards required in these sectors.

Additionally, spindle motors are widely used in the woodworking, medical, and electronics industries. For example, they are integral to PCB drilling, laser engraving, and medical device manufacturing, where reliability, precision, and consistent performance are paramount. The adaptability of spindle motors makes them indispensable in numerous specialized applications across diverse sectors.

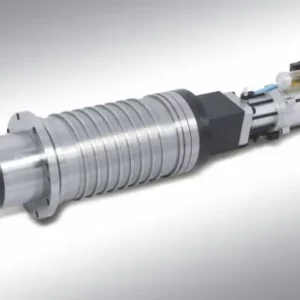

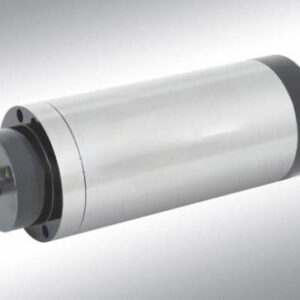

Spindle Motor Used for Lathe

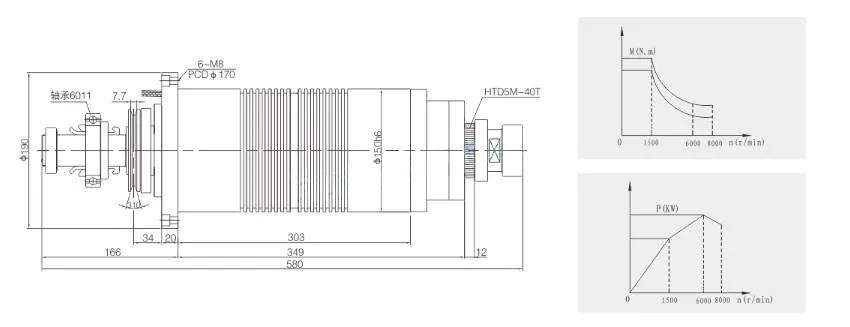

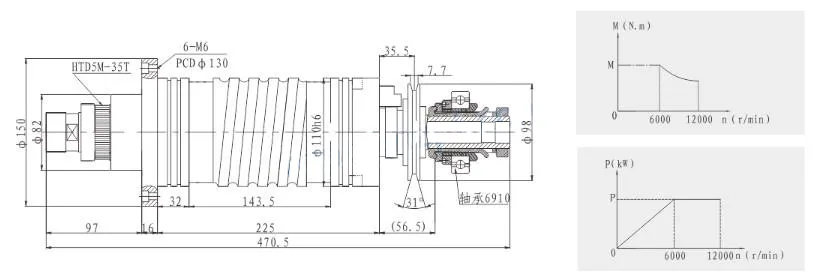

Spindle motors are critical components in lathe machines, where they provide the rotational power required for turning operations. In a lathe, the spindle motor drives the rotation of the workpiece, while tools perform various operations such as cutting, drilling, and threading. These motors are designed to deliver consistent torque and speed, ensuring the smooth operation of the lathe while maintaining precision, particularly in high-demand tasks like high-speed machining or heavy-duty cutting.

Lathe spindle motors are typically high-torque, low-speed motors that can also handle variable speed adjustments, allowing the operator to fine-tune the motor’s performance to suit the specific material and cutting operation. This flexibility is vital for machining a variety of metals, plastics, and composites with different cutting characteristics. By offering smooth acceleration and deceleration, spindle motors help minimize vibration and maintain the dimensional accuracy of the workpiece.

With advanced cooling mechanisms, such as liquid or air cooling, lathe spindle motors can operate at higher power levels without overheating, ensuring durability and long service life. Their precision and reliability make them indispensable for industries like automotive, aerospace, and manufacturing, where high-quality, precise parts are produced consistently.

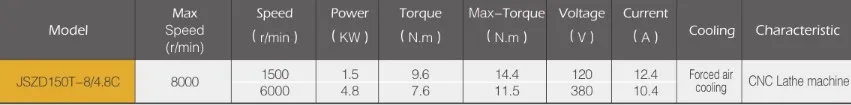

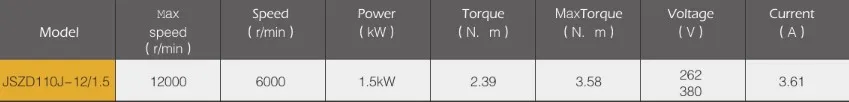

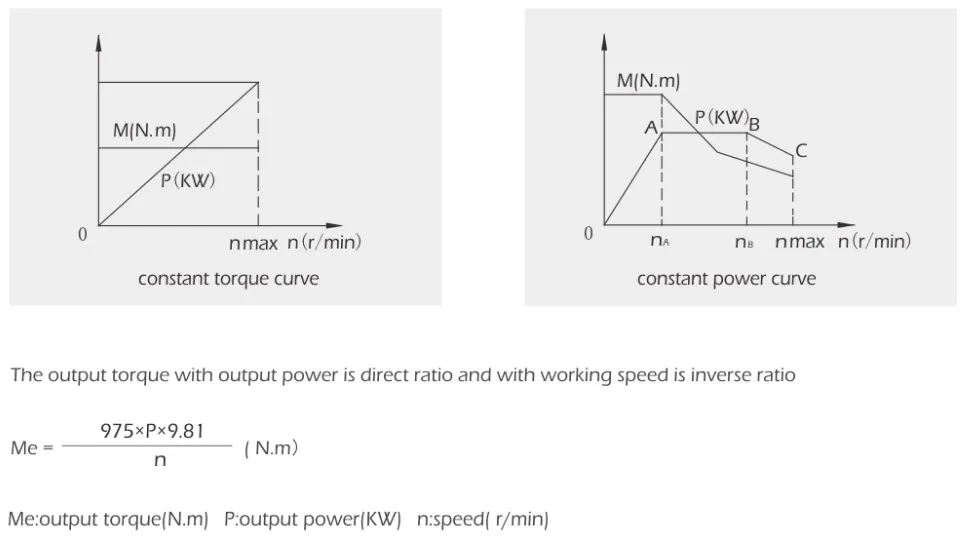

There are Two Ways for the Output One is Constant Torque, and Another is Constant Power as Below:

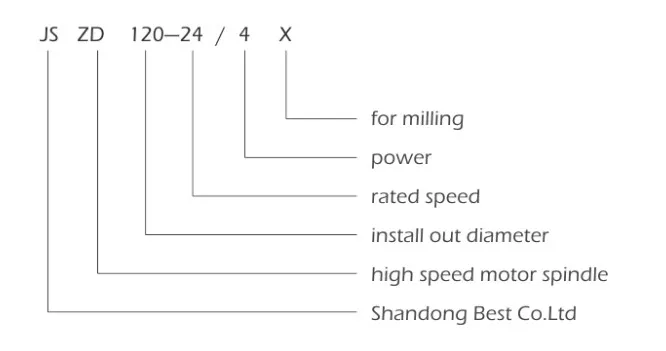

Nomenclature Explanation of Motor Spindle

The End of the Spindle Connection

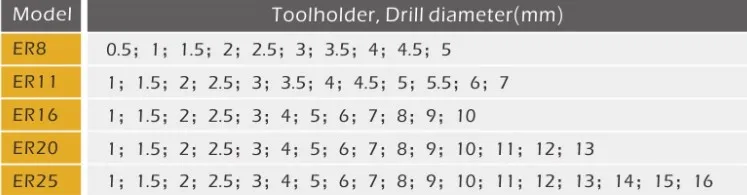

Its have many different types of connection, depending on the different model spindle, please refer to the table below.

Spindle Instruction

2. Electric spindle is generally cooled by circulating water. Cooling water needs to be rust-proof and filtered clean. When acquiring water, the inlet must be under the electric spindle.

three. When working with an oil mist lubricated spindle, the stress regulating valve on the oil mist gadget should be adjusted to 0.25~0.3 MPA the fog pressure should be 0.1~0.2 MPA and the variety of drops of oil must be 60-70 drops/min. and also the lubricating oil ought to be bell oil or turbine oil No. 20.

four. The velocity around the motorized spindle guide is definitely the highest velocity, and it can not be elevated, nevertheless, it may be employed to reduce

the pace, voltage, and frequency are reduced once the speed is lowered.

5. The rotation course with the motorized spindle is usually counter-clockwise (viewed in the shaft). except for exclusive

demands.

6. The motorized spindle lubricated by oil mist has to be linked with water and gasoline prior to it could possibly commence and cease water and fuel supply after shutdown.

Explanation: unique operation is required according to the electric spindle guidelines.

Author: CX