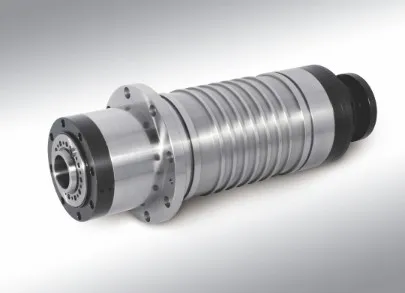

Spindle Motor Used for Lathe JSZD150H

Spindle motors have many advantages over other types of motors, including small size, high reliability, and low power consumption. They can also run for thousands of hours without trouble and are very quiet. This allows them to be installed in smaller spaces, and the tracks take up less space. The tracks are concentric circles of magnetic material around the spindle motor shaft.

Features of Spindles Utilized for Lathe

- High Torque and Power Transmission

Spindles used in lathes are designed to provide consistent high torque, allowing for efficient material removal even under heavy cutting loads. This ensures smooth operation and the ability to handle tough materials without sacrificing performance. - Variable Speed Control

Lathe spindles often feature variable speed capabilities, enabling operators to adjust the spindle speed to suit different machining tasks. This flexibility is crucial for processing various materials, from metals to plastics, and ensures optimal cutting conditions for precision work. - Precision and Stability

Lathe spindles are engineered for high precision and minimal runout, ensuring the workpiece rotates accurately along its axis. This precision is critical in producing parts with tight tolerances and achieving fine surface finishes, especially in high-end applications like aerospace or automotive manufacturing. - Durability and Heat Resistance

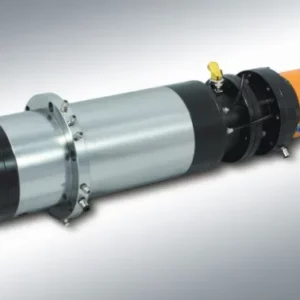

Given the demanding nature of lathe operations, spindles are built to withstand prolonged use at high speeds and with varying loads. Many lathe spindles come with advanced cooling systems, such as air or liquid cooling, to dissipate heat and ensure stable performance over extended periods. - Low Vibration and Noise

High-quality lathe spindles are designed to minimize vibrations and noise, which are critical for maintaining part accuracy and creating a quieter working environment. Low vibration levels also contribute to better tool life and workpiece quality.

Overall, lathe spindles are designed for reliability, precision, and versatility, making them a crucial component in ensuring the high performance and efficiency of lathe machines across a wide range of applications.

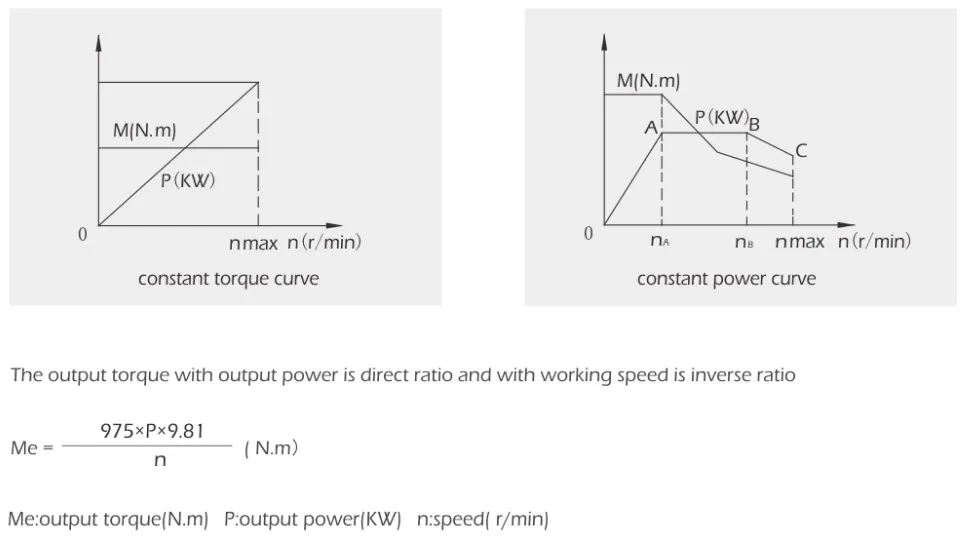

There are Two Ways for the Output One is Constant Torque, and Another is Constant Power as Below:

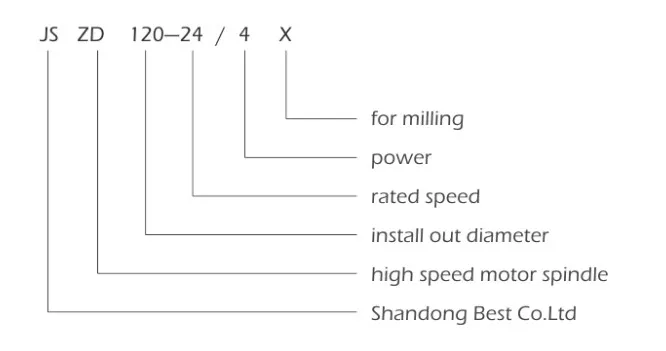

Nomenclature Explanation of Motor Spindle

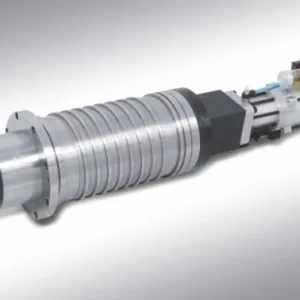

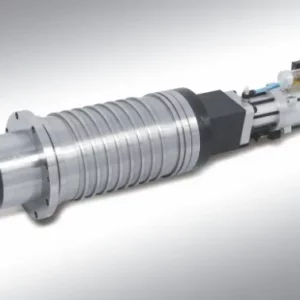

The End of the Spindle Connection

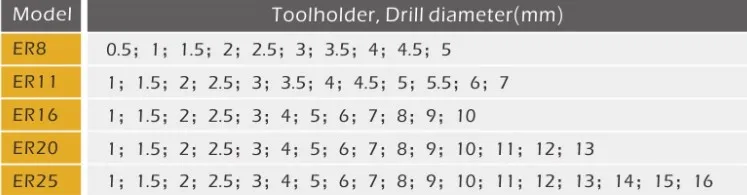

Its have many different types of connection, depending on the different model spindle, please refer to the table below.

Spindle Instruction

2. Electric spindle is generally cooled by circulating water. Cooling water needs to be rust-proof and filtered clean. When acquiring water, the inlet must be under the electric spindle.

three. When working with an oil mist lubricated spindle, the stress regulating valve on the oil mist gadget should be adjusted to 0.25~0.3 MPA the fog pressure should be 0.1~0.2 MPA and the variety of drops of oil must be 60-70 drops/min. and also the lubricating oil ought to be bell oil or turbine oil No. 20.

four. The velocity around the motorized spindle guide is definitely the highest velocity, and it can not be elevated, nevertheless, it may be employed to reduce

the pace, voltage, and frequency are reduced once the speed is lowered.

5. The rotation course with the motorized spindle is usually counter-clockwise (viewed in the shaft). except for exclusive

demands.

6. The motorized spindle lubricated by oil mist has to be linked with water and gasoline prior to it could possibly commence and cease water and fuel supply after shutdown.

Explanation: unique operation is required according to the electric spindle guidelines.

Author: CX