Choosing the Right CNC Spindle Motor Type

Selecting the appropriate CNC spindle motor is essential for optimizing performance, precision, and efficiency in machining operations. The right motor ensures the machine can handle the required workload while achieving the desired output quality. Here are key factors to consider when choosing a CNC spindle motor:

- Power and Torque Requirements

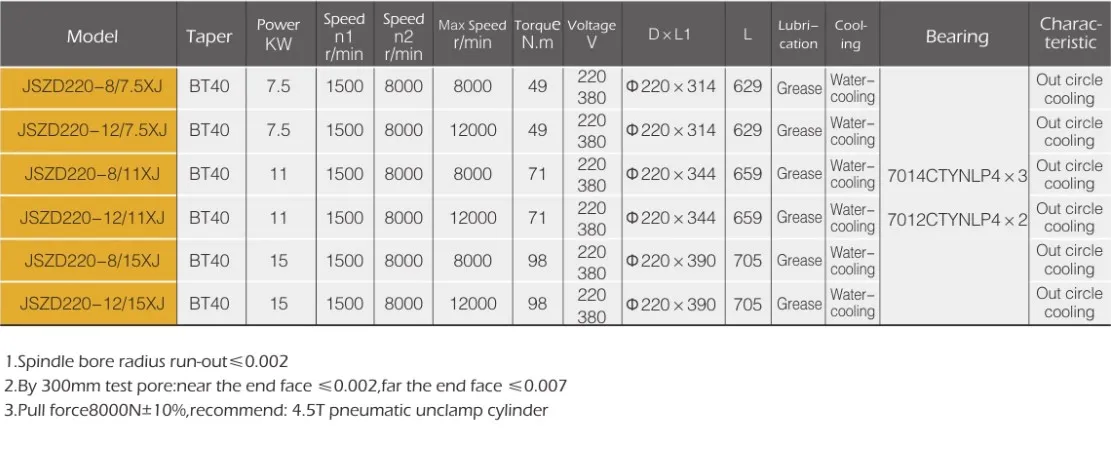

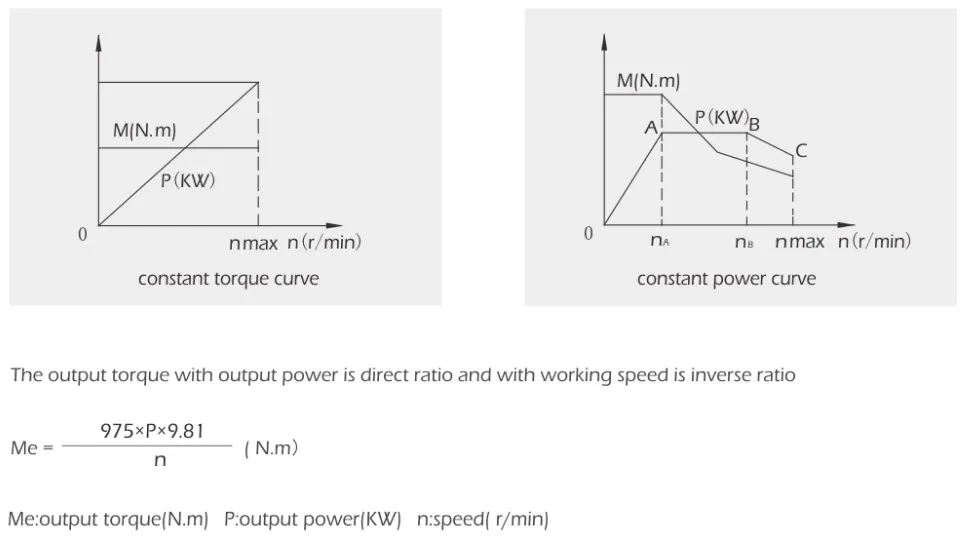

The motor’s power (measured in horsepower or kilowatts) and torque ratings directly impact its ability to handle different materials and cutting operations. For heavy-duty applications, such as milling or deep cutting, a high-torque motor is necessary. For finer, precision work, lower power motors with high-speed capabilities may be more appropriate. Assess the specific machining tasks to determine the required motor power and torque. - Speed Range and Control

CNC spindle motors are available in a wide range of speeds, typically measured in revolutions per minute (RPM). Some applications require high-speed spindles for processes like drilling or engraving, while others, such as threading or rough cutting, may demand lower speeds with higher torque. The motor should have variable speed control to adjust the spindle’s RPM for different materials and operations, ensuring versatility and optimizing performance. - Cooling System

Spindle motors generate heat during operation, especially in high-power or continuous use scenarios. Choosing a motor with an appropriate cooling system, such as air or liquid cooling, helps to maintain optimal performance and prevent overheating. Liquid-cooled spindles are typically more efficient for long-duration or high-power tasks, while air-cooled motors are often sufficient for light-duty applications. - Precision and Runout

The precision of the spindle motor is critical for high-accuracy machining. Motors with low runout (the amount of deviation from true rotational axis) ensure that the workpiece is held securely and rotates uniformly, leading to better dimensional accuracy and surface finishes. High-precision spindles are essential for industries requiring tight tolerances, such as aerospace or medical device manufacturing. - Motor Type: AC vs. DC

CNC spindle motors are generally either AC (alternating current) or DC (direct current). AC motors are typically preferred for industrial CNC applications due to their reliability, better power efficiency, and longer lifespan. They are ideal for high-speed and high-torque operations. DC motors, while offering excellent torque at low speeds, are often more suitable for smaller or more specialized CNC machines with lower power demands.

Selecting the right CNC spindle motor requires a balance of factors, including power, speed, cooling, precision, and compatibility with the machine’s control system. By carefully considering these factors, manufacturers can choose a spindle motor that enhances the CNC machine’s performance, improves machining efficiency, and delivers the desired quality for specific applications.

There are Two Ways for the Output One is Constant Torque, and Another is Constant Power as Below:

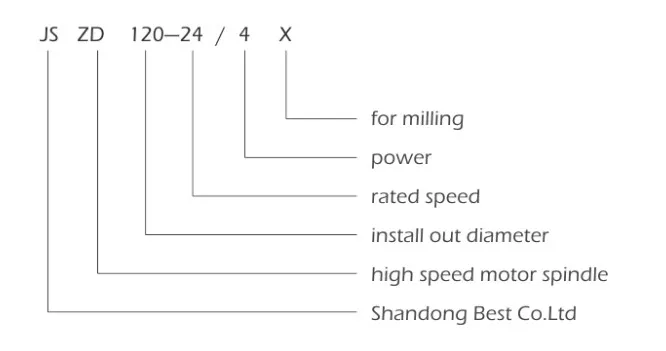

Nomenclature Explanation of Motor Spindle

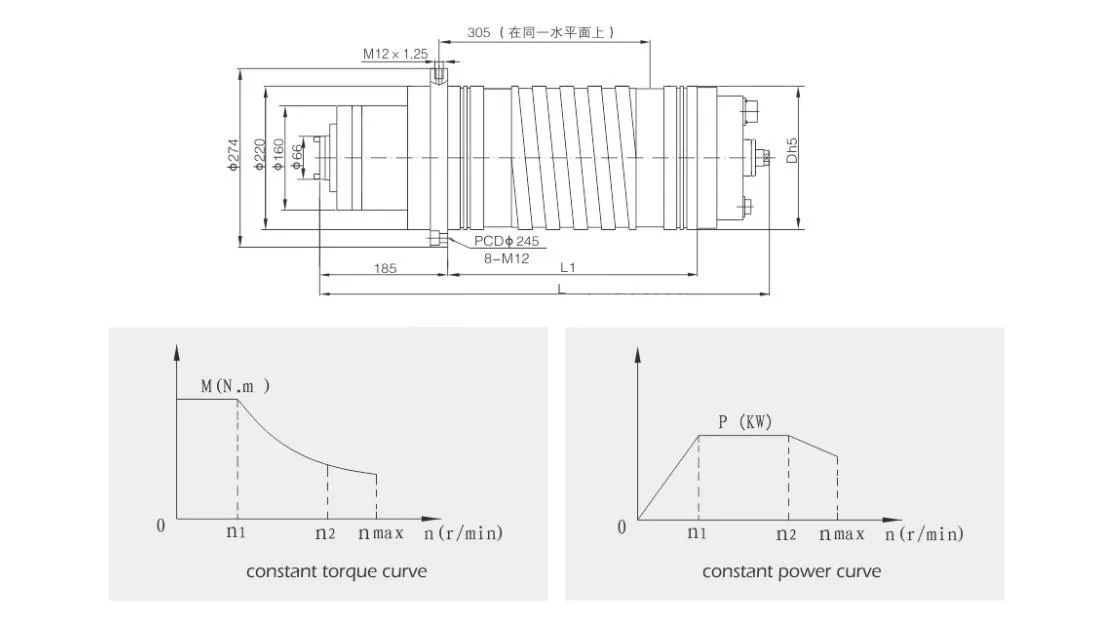

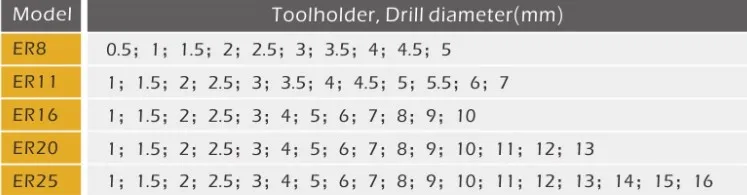

The End of the Spindle Connection

Its have many different types of connection, depending on the different model spindle, please refer to the table below.

Spindle Instruction

2. Electric spindle is generally cooled by circulating water. Cooling water needs to be rust-proof and filtered clean. When acquiring water, the inlet must be under the electric spindle.

three. When working with an oil mist lubricated spindle, the stress regulating valve on the oil mist gadget should be adjusted to 0.25~0.3 MPA the fog pressure should be 0.1~0.2 MPA and the variety of drops of oil must be 60-70 drops/min. and also the lubricating oil ought to be bell oil or turbine oil No. 20.

four. The velocity around the motorized spindle guide is definitely the highest velocity, and it can not be elevated, nevertheless, it may be employed to reduce

the pace, voltage, and frequency are reduced once the speed is lowered.

5. The rotation course with the motorized spindle is usually counter-clockwise (viewed in the shaft). except for exclusive

demands.

6. The motorized spindle lubricated by oil mist has to be linked with water and gasoline prior to it could possibly commence and cease water and fuel supply after shutdown.

Explanation: unique operation is required according to the electric spindle guidelines.

Author: CX