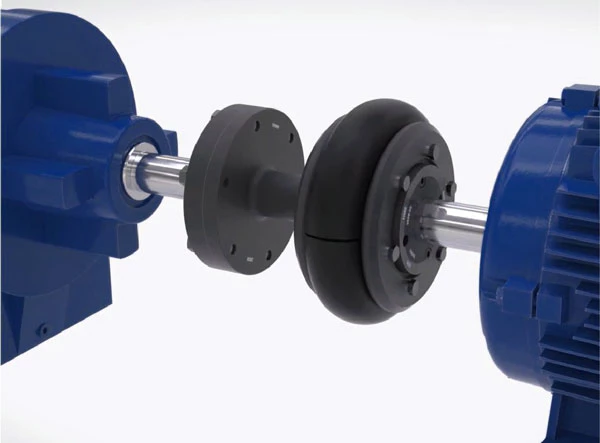

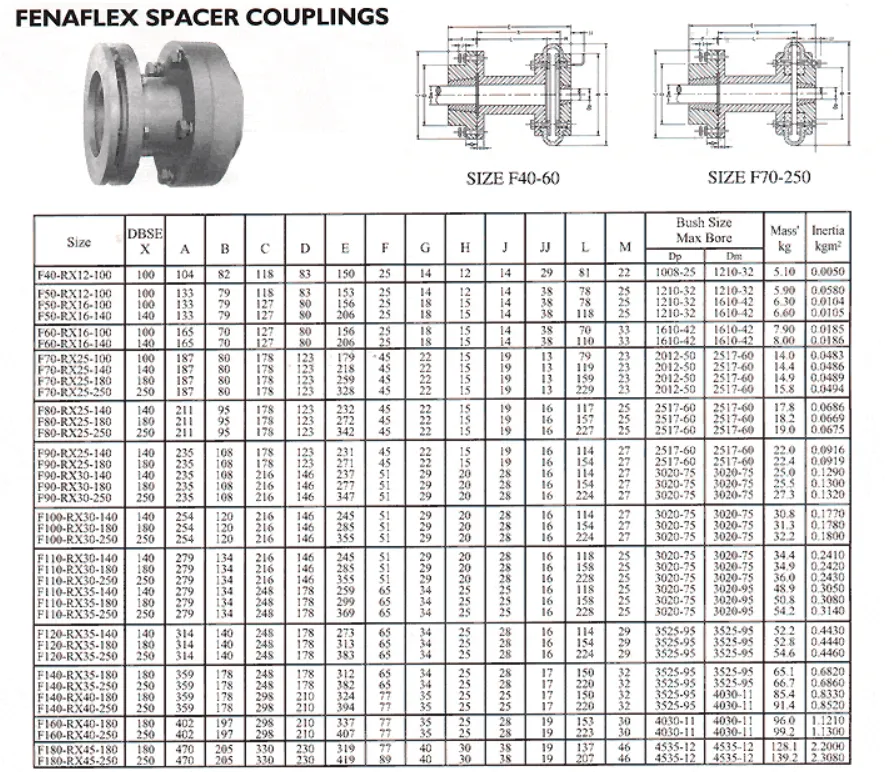

Fenaflex spacer couplings are made up of Fenaflex tire couplings (sizes F40-F140) and spacer flange assemblies. These couplings are designed to make it easier to move one of the shafts back and forth without disturbing the machine or drive it’s connected to, like in a centrifugal pump rotor.

They are made to fit standard distances of 80, 100, 140, and 180 mm between the ends of the shafts. These couplings are very flexible and durable, giving engineers and designers different options to fit a variety of uses by choosing the right coupling flanges.

Features of the Replacement of Fenaflex Spacer Couplings

1. Simplified Installation & Alignment Flexibility

- Easy Setup: Designed for quick, straightforward installation, reducing downtime.

- Superior Misalignment Tolerance: Accommodates angular misalignment up to 4 degrees, parallel displacement of 6mm, and radial offset of 8mm across all planes.

2. Robust Construction & Versatile Design

- Bidirectional Internal Load-Carrying Wire: Reinforced with wire wound in both directions, enabling reliable performance in reverse drive applications.

- Material Options: Tires are available in standard or FRAS (Fire Resistant Anti-Static) construction, compliant with ATEX certification for hazardous environments.

- Adaptable Mounting: Supports pump spacer and flywheel configurations, with flanges featuring F&H locking ring tapered bushings or B-type pilot-drilled designs for universal compatibility.

3. Enhanced Performance Over Traditional Couplings

- High Elasticity & Zero Lubrication: Unlike conventional tire couplings, the replacement of Fenaflex couplings eliminate the need for lubrication while offering superior flexibility and elasticity.

- Vibration Damping: Exceptional shock and torsional vibration absorption, protecting connected equipment from dynamic stresses.

4. Maintenance & Service Advantages

- Modular Design: An intermediate spacer (DBSE) allows maintenance of centrifugal pumps without displacing motors or machinery during tire replacement.

- Inspection-Friendly: Simple design enables easy visual checks and part replacement without disassembling the entire drive system.

5. Customizable Solutions

- Spacer Adaptability: Intermediate devices can be integrated to adjust spacing between shaft diameters, ensuring compatibility with diverse system requirements.

Key Benefits Summary

- Durability: Engineered for heavy-duty applications with minimal wear.

- Safety: FRAS and ATEX certifications ensure compliance in fire-prone or explosive environments.

- Cost Efficiency: Reduced maintenance needs and extended service life lower operational costs.

The replacement of Fenaflex Spacer Couplings combine flexibility, resilience, and user-friendly design, making them ideal for industries demanding reliability in high-misalignment, high-vibration, or hazardous conditions.