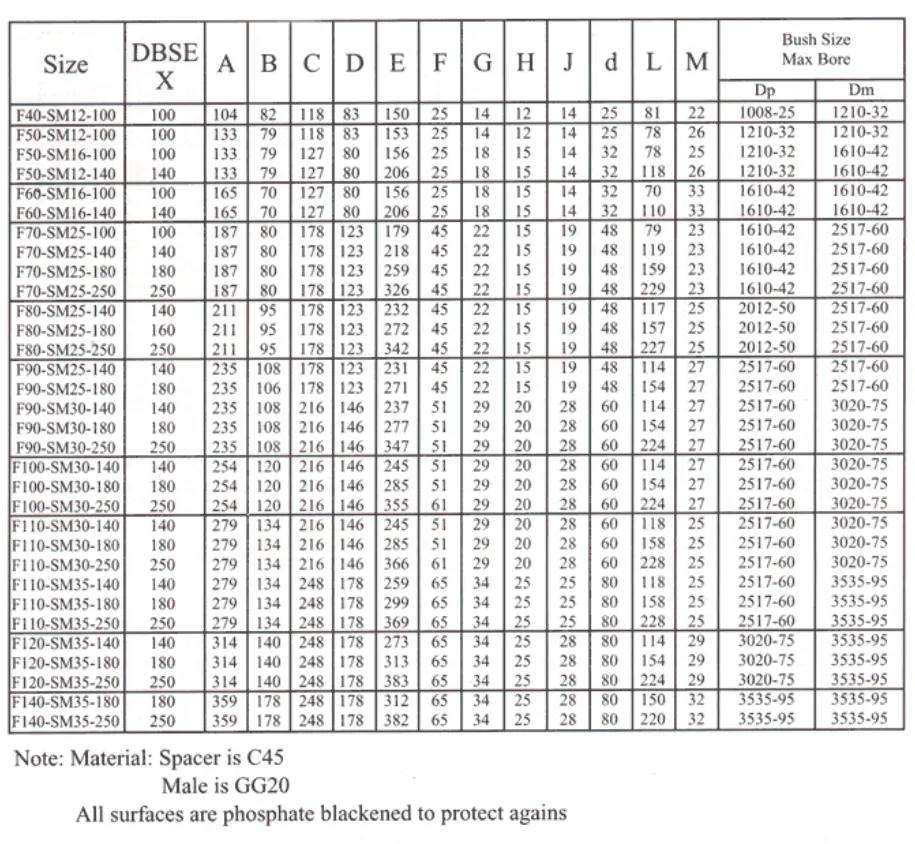

Spacer Coupling vs. Flexible Coupling

- Primary Function:

- Spacer Coupling: Designed to maintain a specific distance between two connected shafts. Commonly used when equipment (e.g., pumps, motors) cannot be positioned close together. The spacer acts as a rigid or adjustable component to bridge the gap.

- Flexible Coupling: Focuses on accommodating misalignment (angular, parallel, or axial) and absorbing vibrations/shock loads. It allows movement between shafts without transmitting excessive stress to connected machinery.

- Design and Flexibility:

- Spacer Coupling:

- Can be rigid (for precise alignment in fixed setups) or flexible (combining spacing with misalignment tolerance).

- Examples include rigid spacer sleeves or flexible spacer designs with elastomeric elements.

- Flexible Coupling:

- Prioritizes flexibility through materials like elastomers (e.g., rubber in jaw couplings) or mechanical elements (e.g., metallic springs in disc couplings).

- Types include jaw, gear, disc, and elastomeric couplings.

- Spacer Coupling:

- Applications:

- Spacer Coupling:

- Used in scenarios requiring fixed shaft separation, such as large industrial machinery, marine propulsion systems, or conveyor belts.

- Flexible Coupling:

- Applied in systems with expected thermal expansion, vibration, or misalignment, like automotive drivetrains, HVAC systems, or turbines.

- Spacer Coupling:

- Installation and Maintenance:

- Spacer Coupling:

- Often requires precise alignment during installation, especially rigid types. Maintenance may involve checking spacer integrity.

- Flexible Coupling:

- Tolerates minor misalignment, easing installation. Maintenance focuses on wear of flexible elements (e.g., replacing rubber inserts).

- Spacer Coupling:

- Material Considerations:

- Spacer Coupling: Typically metallic (steel, aluminum) for durability in maintaining distance. Flexible variants may include elastomers.

- Flexible Coupling: Combines metals with flexible materials (rubber, urethane) or uses flexible metal components (e.g., stainless steel discs).

Some couplings integrate both features (e.g., flexible spacer couplings), offering both spacing and misalignment accommodation. However, the core distinction remains their primary purpose: spacing vs. flexibility. Choose a spacer coupling when distance is critical, and a flexible coupling when movement or misalignment is the main concern.