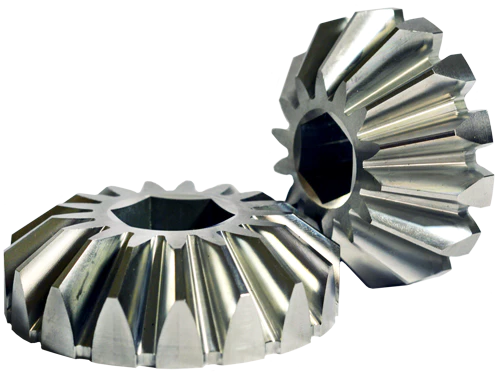

About Sintered Metal bevel gears

Sintered metal bevel gears are precision-engineered components made through a sintering process, where metal powders are compacted and heated to form strong, durable gears with a conical shape. These gears are widely used in various industries for their ability to transmit motion and power between intersecting shafts, typically at a 90-degree angle. They offer advantages such as high strength, wear resistance, and cost-effectiveness due to the powder metallurgy process.

At FMP Company, we specialize in producing a wide range of sintered metal bevel gears to meet diverse application needs. We also offer customization services to tailor our products to your specific requirements. If you don’t find the exact model you need in our product list, it simply means we haven’t had the chance to update it yet. Please feel free to email us with your desired specifications, and our engineers will respond within 24 hours to assist you.

Specification

| Model Number | M3,M4,M5,M8,M12 and etc. |

| Material | Brass, C45 steel, Stainless steel, Copper, POM, Aluminum, Alloy, and so on |

| Surface treatment | Zinc-plated, Nickel plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating, and Electrophoresis |

| Standard | ISO, DIN, ANSI, JIS, BS, and Non-standard. |

| Precision | DIN6,DIN7,DIN8,DIN9. |

| Teeth treatment | Hardened, Milled, or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sandblast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, L/C |

| Production lead time | 20 business days for sample,25 days for the bulk |

| Samples | Sample price range from $2 to $100. sample express request paid by clients |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |