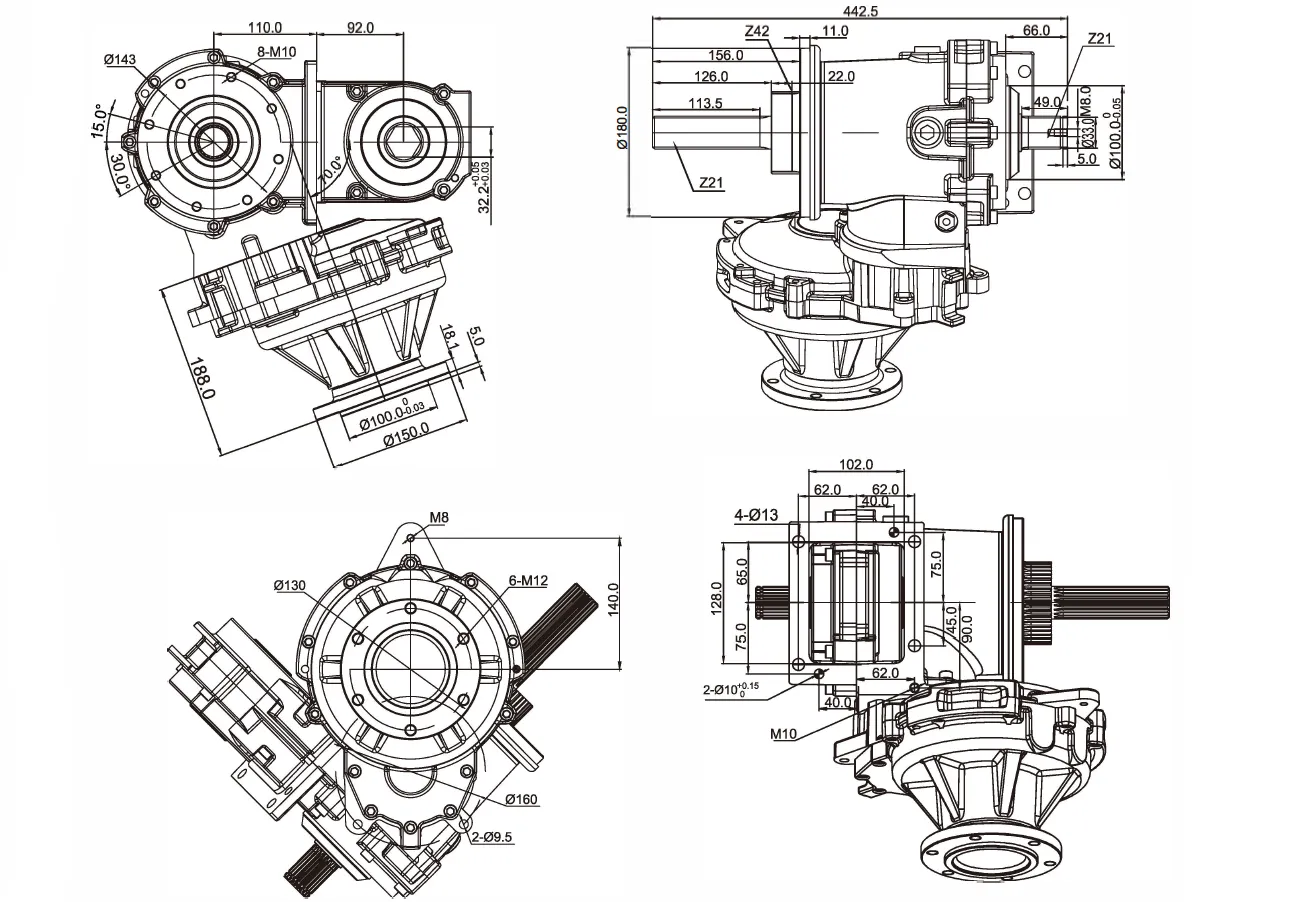

Silage Machine Gearbox FMP-QZ-WRXL Dimensions

Silage Machine Gearbox FMP-QZ-WRXL Technical Data

| Name | Suitable | Turn | header series | Toothing |

| Feeding box | silage machines | left turn | 3 series | Gleason Helical Teeth |

| Remark: If you have any special require feel free let me know, we also accept custom. | ||||

Working Principle of Silage Machine Gearbox for German Champion Four Disc (Type 3500)

The silage machine gearbox for a German Champion Four Disc (Type 3500) operates by transmitting power from the tractor’s PTO shaft to the various components of the silage machine, enabling it to perform tasks such as cutting, shredding, and chopping silage efficiently. The gearbox’s primary function is to reduce the rotational speed of the PTO while increasing torque, thereby allowing the machine to handle the heavy loads involved in the silage process.

Here’s a detailed breakdown of the working principle of the gearbox in the context of a German Champion Four Disc (Type 3500):

1. Input from PTO Shaft

The gearbox is powered by the PTO (Power Take-Off) shaft, which is connected to the tractor. When the tractor’s engine turns on, the PTO shaft begins to rotate. This rotational motion is transferred to the gearbox.

2. Torque and Speed Reduction

The gearbox is designed to reduce the speed from the high rotation speed of the tractor’s PTO (often around 540 or 1000 RPM, depending on the PTO type) to a slower speed suitable for operating the cutting discs. This is achieved through a system of gears, typically involving planetary gears or helical gears, which adjust the rotational speed while increasing the output torque. This reduction in speed and increase in torque ensures the machinery operates efficiently under heavy load conditions.

3. Power Distribution to the Cutting Discs

The gearbox transmits power to the four discs that are responsible for cutting or chopping the silage. Each disc is driven by a shaft that is linked to the output of the gearbox. These cutting discs are often mounted in a specific configuration (e.g., in a star-shaped or circular arrangement) and rotate at a much slower speed than the input speed from the tractor’s PTO.

4. Mechanical Efficiency and Load Management

The gearbox helps maintain mechanical efficiency by distributing the load evenly among the four discs. It does so by ensuring the torque generated from the tractor’s PTO is efficiently transmitted to each disc. This allows the silage machine to process large amounts of material quickly and evenly, without overloading individual components.

5. Lubrication and Cooling

Given the heavy loads and continuous operation, the gearbox typically contains a lubrication system to reduce friction and wear between the gears. This system ensures smooth operation and extends the lifespan of the gearbox. Some gearboxes may also include a cooling system to prevent overheating during prolonged use.

In essence, the silage machine gearbox in the German Champion Four Disc (Type 3500) efficiently manages power transmission and ensures that the silage cutting process is carried out smoothly and effectively, even under heavy operational conditions.

Applications of Silage Machine Gearbox for German Champion Four Disc (Type 3500)

The silage machine gearbox for the German Champion Four Disc (Type 3500) plays a critical role in the operation of silage harvesting equipment. This gearbox, designed for optimal power transmission, is utilized in a variety of applications within the agricultural industry. Below are some key applications of this gearbox:

1. Silage Harvesting

- Primary Application: The primary function of the silage machine gearbox is to facilitate the cutting, chopping, and processing of silage. It powers the four cutting discs on the machine, enabling them to slice through forage crops (like corn, grass, alfalfa, or legumes) and convert them into finely chopped material for animal feed.

- Crop Types: This gearbox is suitable for harvesting a range of crops used in silage production, including corn, grass, sorghum, and other green fodder crops. It can be adapted for both high-moisture crops (such as corn) and dry crops (like alfalfa).

2. Forage Chopping and Processing

- The gearbox drives the cutting and chopping mechanisms, which are essential for breaking down large forage stalks into smaller pieces. The efficient power transfer from the gearbox allows the machine to cut with precision, ensuring uniform chop lengths. This process is vital for fermentation in silage storage and the quality of the final feed product.

3. Haylage Production

- While primarily used for silage, the gearbox is also essential in haylage production, which involves cutting and storing forage at a higher moisture content than traditional hay. Haylage is often used for feeding livestock, and the gearbox ensures that the machine cuts and processes the forage efficiently to preserve the moisture levels necessary for quality haylage.

4. Grass and Legume Silage

- The gearbox is utilized in the preparation of grass and legume silage, which is especially important for dairy farmers and livestock operations. These types of silage provide high-quality feed, and the gearbox ensures smooth and continuous chopping of grasses like timothy, ryegrass, or clover.

5. Precision Agriculture

- In modern precision farming, silage machines with advanced gearboxes, like the German Champion Four Disc (Type 3500), are used in conjunction with GPS and sensor technologies to optimize the harvesting process. The gearbox ensures that the machine operates at the correct speed and power to handle variable crop conditions, improving efficiency and reducing fuel consumption.

In summary, the silage machine gearbox for the German Champion Four Disc (Type 3500) plays an integral role in silage production by enabling efficient and consistent crop processing. It is versatile, reliable, and essential for various applications in modern agriculture, particularly in large-scale silage harvesting, forage processing, and precision farming.

About FMP

Headquartered in Italy, FMP is a premier manufacturer specializing in the design, development, and production of high-performance gearboxes, with a particular emphasis on the agricultural machinery sector. Renowned for our precision engineering, innovative solutions, and unwavering reliability, FMP has built a strong reputation as a trusted partner for both the agricultural and industrial sectors. Our diverse product range includes custom-engineered gearboxes for lawn mowers, PTO shafts, and various other essential components, all designed to meet the specific demands of a wide array of applications.

At FMP, we understand that each client faces unique challenges. That’s why we focus on providing tailored solutions, whether for individual components or fully integrated systems. By working closely with our customers, we ensure that every solution not only addresses their specific needs but also enhances performance and delivers maximum value. Our commitment to fast, professional service, combined with expert advice, ensures that each inquiry is handled with precision and care, resulting in the best possible outcomes.

Open and continuous communication is central to our approach. Our dedicated team collaborates directly with clients throughout the product development cycle to fully understand their requirements, offering valuable insights and recommendations to ensure optimal results. Whether developing cutting-edge products or fulfilling recurring orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our mission is to exceed client expectations by consistently providing exceptional service and outstanding results with every project.

Quality is the cornerstone of everything we do. We adhere to the highest manufacturing standards and enforce rigorous quality control procedures to ensure that every product meets, and often exceeds, industry benchmarks. This relentless pursuit of excellence, alongside our core values of integrity, teamwork, and perseverance, has enabled us to cultivate long-term, trust-based relationships with clients in nearly 30 countries worldwide.

FMP is always eager to build and strengthen global partnerships. We are committed to offering expert guidance and customized solutions that evolve with our clients’ needs. We don’t just supply products; we focus on creating lasting relationships that contribute to the success of each project. Whether you require innovative solutions for a new venture or ongoing support for an existing system, FMP is here to address your technical challenges and ensure your continued success.

Author: CX