Sanitation Machinery Reverse Thrust Hydraulic Cylinder

The Sanitation Machinery Reverse Thrust Hydraulic Cylinder is an essential component designed to provide reliable reverse thrust for various sanitation equipment, including garbage trucks and street sweepers. This hydraulic cylinder is engineered to facilitate smooth and controlled movements, allowing for effective engagement and disengagement of machinery functions during waste collection and cleaning operations.

Key Features:

- Durable Construction: Made from high-strength materials, this hydraulic cylinder is built to withstand the rigorous demands of sanitation work, ensuring long-lasting performance in harsh environments.

- Smooth Hydraulic Operation: The advanced hydraulic system enables responsive and fluid motions, minimizing wear on equipment and enhancing overall operational efficiency.

- Enhanced Control: Designed for precise control, the reverse thrust hydraulic cylinder allows operators to navigate and maneuver sanitation machinery effectively, improving safety and performance.

- Versatile Application: Suitable for a wide range of sanitation machinery, this hydraulic cylinder can be seamlessly integrated into various systems, making it a versatile solution for waste management.

- Energy Efficient: Its design optimizes energy usage, reducing power loss and contributing to lower operational costs, making it an environmentally friendly choice.

The Sanitation Machinery Reverse Thrust Hydraulic Cylinder is a critical component that enhances the functionality and efficiency of sanitation equipment, ensuring effective performance in waste management operations while maintaining high levels of durability and control.

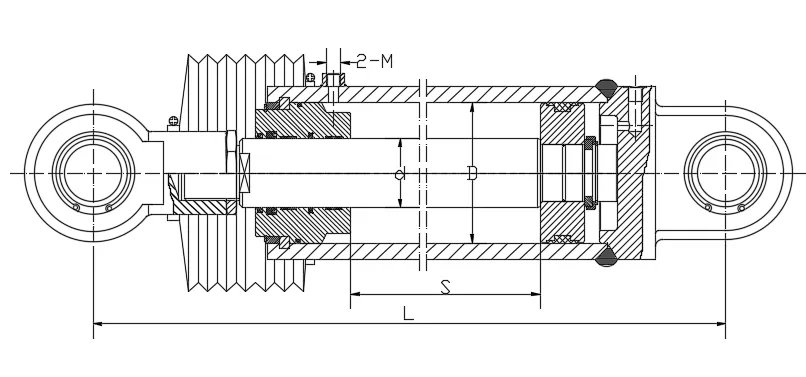

Sanitation Machinery Reverse Thrust Hydraulic Cylinder Dimensions:

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Reverse thrust cylinder | LPE222.2.2-5-00 | Φ220 | Φ110 | 420 | 1110 | 16MPa | 2-M22*1.5 | 323kg |

Hydraulic Cylinder Available Brand & Models:

| KOMATSU (PC) | PC30,PC40,PC50,PC56,PC60,PC78,PC100,PC110,PC120,PC130,PC160,PC200-3/5/6/7/8/8MO,PC210,PC220-5/6/7/8/8MO,PC240,PC300/350/360-5/6/7/8/8MO,PC400/450-5/6/7/8/8MO,PC800,PC850 |

| CATERPILLAR (E) | E301.5,E302,E305.5,E306,E307V1/V2/B/C/D/E/F,E308B/C,E120B,E312V1/V2/B/C/D,E313D2,E312D2,E315D, E200B,E320V1/V2/A/B/C/D,E324D,E325C/D,E329D,E330/336C/D,E345C,E349D,E365C,E374,E390 |

| KOBELCO (SK) | SK60-3/5/8,SK75-8/SR, SK100 ,SK120-3/5, SK135-8/SR, SK140-8, SK200-3/5/6/6E, SK210-3/5/6/6E, SK230/250-6E,SK250-8,SK260-8,SK350-8/S8,SK460/480-8 |

| HYUNDAI (R) | R55-5/7, R60-5/7, R80, R110,R130, R200-5, R210-5, R215-5/7,R220-5/7/9, R225-5/7/9, R250,R260,R265,R290,R305,R445,R485, R505 |

| HITACHI (EX.ZX) | EX60,EX100-1/2/3,EX120-1/3/5/6,EX200-1/3/5,EX230-5,EX300-1,EX400 ZAX60,ZAX70,ZA120-6,ZAX200/210-1/3/5/5K,ZAX240,ZAX250,ZAX260,ZAX330-3/5/6,ZAX450/470,ZAX650/670,ZAX850/870 |

|

DOOSAN (DH/DX)

|

DH55, DH60, DH80,DH150, DH215-5/7,DH220-5,DH225-5/7,DH258,DH300-5/7, DH370,DH420,DH500

DX55,DX60,DX75,DX130,DX225-9,DX300,DX380,DX420,DX500 |

|

VOLVO (EC)

|

EC55 ,EC60,EC75,EC80,EC140 ,EC210B/D,EC220D,EC240 ,EC250,EC290,EC300, EC360 EC380,EC460,EC480,EC700,EC750,EC950

|

|

KATO (HD)

|

HD307/308,HD450,HD512,HD700-5/7,HD820-1/2/3/5/R,HD1023-1/3,HD1430-1/3

|

|

OTHER BRAND

|

XCMG,LIUGONG,KUBOTA,CASE,YANMAR,SUNWARD,ZOOMLION,LISHIDE,LIEHERR

|

Advantages of Sanitation Machinery Reverse Thrust Hydraulic Cylinder

1. Enhanced Control

The Sanitation Machinery Reverse Thrust Hydraulic Cylinder provides precise control over the reverse thrust movements of sanitation equipment. This capability allows operators to maneuver effectively, improving the overall efficiency of operations such as waste collection and street cleaning.

2. Robust Durability

Designed to endure the harsh conditions of sanitation work, this hydraulic cylinder is constructed from high-strength materials. Its durability ensures long-lasting performance, reducing the need for frequent replacements and maintenance.

3. Smooth Operation

The advanced hydraulic system of the reverse thrust cylinder enables smooth and responsive operation. This results in reduced wear on equipment and minimizes the risk of sudden movements, enhancing safety during operation.

4. Versatility

This hydraulic cylinder is versatile and can be used across various sanitation machinery, including garbage trucks and street sweepers. Its adaptability makes it suitable for a wide range of applications in waste management and municipal services.

5. Improved Safety

By providing reliable reverse thrust control, the hydraulic cylinder enhances the safety of sanitation operations. It helps prevent accidents and ensures that machinery operates within safe parameters, protecting both operators and the surrounding environment.

6. Energy Efficiency

The design of the reverse thrust hydraulic cylinder optimizes energy usage, minimizing power loss during operation. This efficiency translates to lower operational costs and contributes to environmentally friendly practices in waste management.

7. Easy Integration

The cylinder is designed for straightforward installation into existing sanitation equipment, allowing for quick upgrades and minimizing downtime during maintenance or replacement.

The Sanitation Machinery Reverse Thrust Hydraulic Cylinder offers numerous advantages, including enhanced control, durability, and safety, making it an essential component for efficient and effective sanitation operations. Its versatility and energy efficiency further contribute to its value in the waste management industry.

About FMP

FMP is a specialized mechanical manufacturing company dedicated to the production of hydraulic cylinders. Since its establishment, the company has focused on the research and manufacturing of hydraulic technology, successfully transitioning from a diverse product range that included harvesting and construction machinery to specializing in agricultural tractor components. With over a decade of experience in manufacturing and management, FMP ensures high-quality products through advanced production techniques.

As the company has evolved, it has developed a comprehensive machining production line, assembly line, and coating line. Our team comprises skilled management personnel, experienced mechanical designers, and highly trained technicians who work together to maintain stable production quality while effectively controlling process continuity and efficiency.

FMP upholds the philosophy of “Technological Innovation Driving Progress, Quality Creating Brands, Craftsmanship Ensuring Quality, and Building Long-Term Win-Win Relationships.” Our commitment to providing high-quality products and superior customer service remains a core objective as we continue to meet the evolving needs of the market.

Author: CX