Specifications of Round Baler Gearbox T-304A (1:3)

| Description |

Round Baler Gearbox – Replacement of Comer Gearbox T-304A 1:3

|

|---|---|

| Product Details |

|

| Application |

|

| Consists of |

|

| Technical information |

|

| Max. output torque |

94.5 daNm

|

| Contains oil |

No

|

| Max. oil capacity |

1.1 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| Weight |

19 kg

|

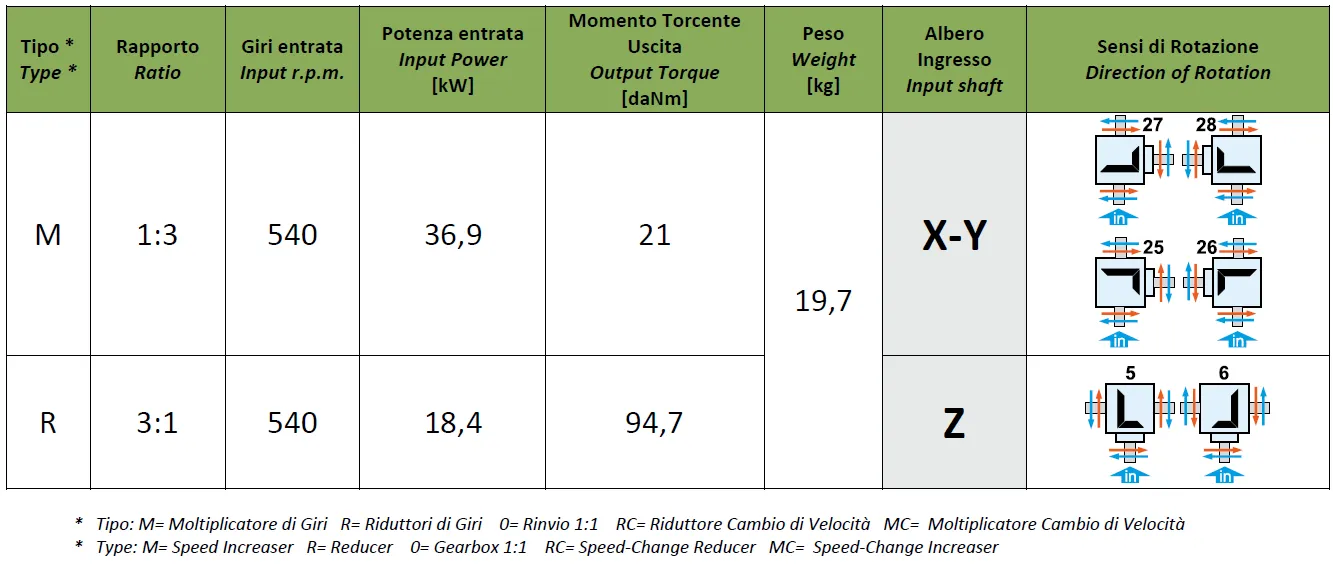

| Gear arrangement Increasing |

25 – 26 – 27 – 28

|

| Gear arrangement Reducing |

5 – 6

|

| Input power kW / HP Increasing |

36.8 / 50 kW/HP

|

| Input shaft Increasing |

X – Y

|

| Input shaft Reducing |

Z

|

| Input power KW / HP Reducing |

18.4 / 25 kW/HP

|

| Output Torque DaNm Increasing |

21 daNm

|

| Ratio Increasing |

1: 3

|

| Ratio Reducing |

3: 1

|

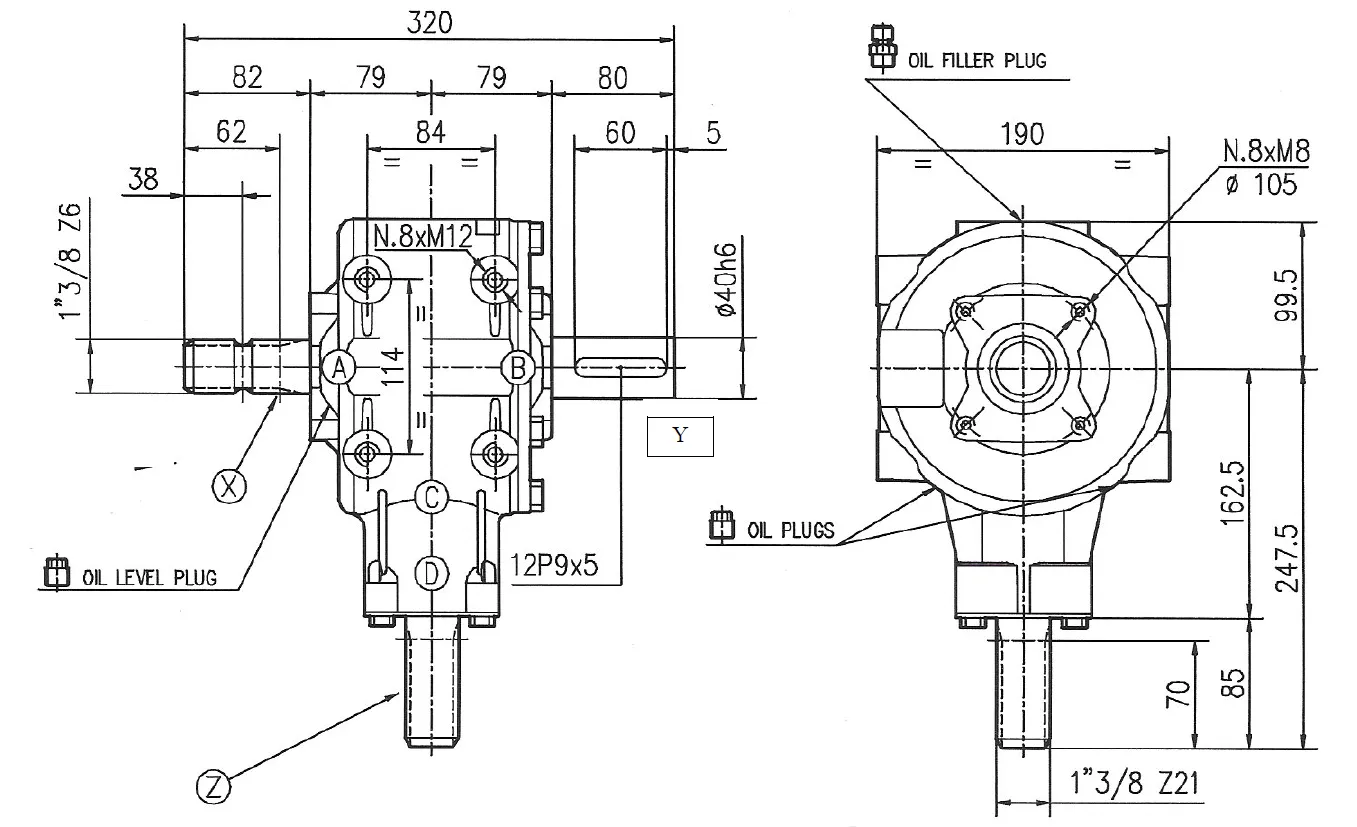

| Shaft X |

1 3/8″ (6) (A)

|

| Shaft Y |

1 3/8″ (6) (A)

|

| Shaft Z |

1 3/8″ Z6

|

Key Features of Round Baler Gearbox T-304A (1:3)

The Round Baler Gearbox T-304A (1:3) is specifically designed for use in round baler applications, offering reliable performance and durability for agricultural operations. Below are the key features of this gearbox:

High Torque Output

The T-304A gearbox is engineered with a 1:3 gear ratio, providing high torque output to efficiently power the round baler. This feature ensures that the baler operates smoothly, even when processing dense or heavy crops. It helps in the consistent formation of uniform bales, even in challenging field conditions.

- Feature: 1:3 Gear Ratio for High Torque.

- Benefit: Consistent and reliable operation for heavy-duty baling tasks.

Durable Construction

Constructed from high-quality materials, the T-304A gearbox is built to withstand the demands of continuous, heavy-duty use in the field. Its durable design ensures longevity, reducing the risk of downtime and minimizing maintenance costs. The robust construction makes it ideal for demanding agricultural environments.

- Feature: High-Strength Materials and Construction.

- Benefit: Long-lasting durability and reliability under heavy use.

Efficient Power Transmission

The gearbox is designed to efficiently transmit power from the tractor’s PTO to the baler’s components, ensuring smooth and uninterrupted operation. The efficient power transmission enhances the overall performance of the round baler, resulting in higher productivity and reduced fuel consumption.

- Feature: Optimized Power Transmission Mechanism.

- Benefit: Improved efficiency, reduced energy loss, and lower operational costs.

Compact Design

Despite its high-performance capabilities, the T-304A gearbox features a compact design, allowing it to be easily integrated into various round baler models. Its space-saving design ensures that it fits without compromising on functionality or performance, making it an ideal choice for a wide range of balers.

- Feature: Compact and Space-Saving Design.

- Benefit: Easy integration into existing baler systems, suitable for various models.

Low Maintenance and Easy to Service

The T-304A gearbox is designed for easy maintenance, with simple access points for lubrication and servicing. Its efficient design reduces wear and tear, minimizing the need for frequent repairs and extending the lifespan of the gearbox. This ease of maintenance helps to keep operational costs low and reduces downtime.

- Feature: Simple Maintenance and Lubrication Access.

- Benefit: Reduced downtime and maintenance costs, ensuring continuous operation.

The Round Baler Gearbox T-304A (1:3) is a highly efficient, durable, and low-maintenance solution for round baler applications. With its high torque output, robust construction, and efficient power transmission, it ensures smooth and consistent performance in the field. Its compact design and ease of maintenance further enhance its appeal, making it a reliable choice for agricultural machinery.

|

|

Applications of Agricultural Round Baler Gearbox T-304A

About FMP

Headquartered in Italy, FMP stands as a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, particularly for the agricultural machinery sector. With a commitment to precision engineering, innovation, and reliability, FMP has earned a reputation as a trusted partner in meeting the evolving needs of both the agricultural and industrial markets. Our extensive product range includes specialized gearboxes for lawn mowers, PTO shafts, and other vital components, all tailored to provide customized solutions across a wide array of applications.

At FMP, we recognize that each client faces distinct challenges. That’s why we specialize in delivering bespoke solutions, whether for individual components or fully integrated systems. We work closely with customers to ensure each solution is not only effective but also optimized for performance and value. Our dedication to providing timely and professional responses, paired with expert guidance, ensures that every inquiry is handled with precision, resulting in the best possible outcomes for our clients.

We prioritize clear, ongoing communication throughout the product development process. Our dedicated team works directly with customers to gain a deep understanding of their needs, offering valuable insights and recommendations to guarantee optimal solutions. Whether we are designing new products or fulfilling existing orders, FMP remains committed to delivering high-quality, precision-engineered solutions that exceed expectations and are delivered on time, every time.

Quality is the cornerstone of our operations at FMP. We adhere to the highest manufacturing standards, employing rigorous quality control measures to ensure that each product not only meets but exceeds industry expectations. This unwavering focus on quality, combined with our core values of integrity, collaboration, and perseverance, has allowed us to establish long-term, trust-based relationships with clients across nearly 30 countries worldwide.

FMP is always eager to foster global partnerships, providing expert advice and customized solutions to meet the diverse needs of our clients. We strive to go beyond simply supplying products; our goal is to build lasting relationships that contribute to the success of every project. Whether you need innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to address your technical challenges and ensure your continued success.

Author: CX