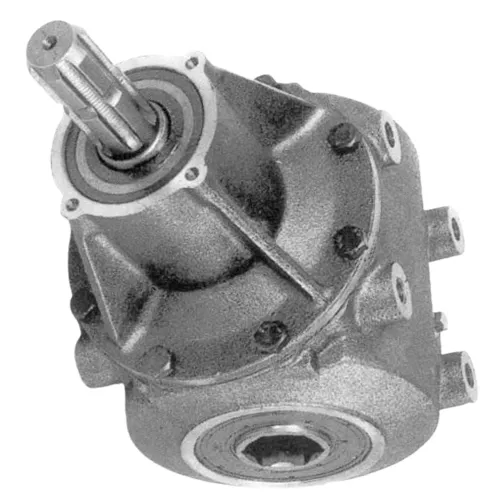

Rotary Tillers Gearboxes – Replacement of Comer Code TB-278C 1:1

The Rotary Tillers Gearbox – Replacement of Comer Code TB-278C 1:1 is a high-performance, durable gearbox designed specifically for use in rotary tillers, offering an efficient solution for soil preparation and land cultivation. This replacement gearbox is engineered to deliver reliable power transmission from the tractor’s PTO to the tiller blades, ensuring smooth operation even in tough agricultural environments.

Key features of the TB-278C gearbox include a 1:1 gear ratio, which provides optimal power transfer for tilling operations, making it highly effective for various types of soil, from light to heavy-duty farming applications. The robust construction ensures resistance to wear and tear, extending the lifespan of the gearbox and reducing maintenance costs. Additionally, the gearbox is designed for easy installation, offering a direct replacement for the Comer TB-278C gearbox, minimizing downtime and ensuring continued productivity in the field.

The TB-278C gearbox is built with precision engineering and high-quality materials, making it a reliable choice for both small-scale farms and large agricultural operations. Its design allows for efficient energy transfer, which maximizes the performance of the tiller and enhances fuel efficiency.

This replacement gearbox is ideal for farmers seeking a high-quality, cost-effective solution to maintain the performance of their rotary tillers. Whether replacing a worn-out gearbox or upgrading an older model, the TB-278C ensures optimal tilling performance and increased productivity. The gearbox also benefits from rigorous quality control standards to meet the high demands of modern agriculture.

The Rotary Tillers Gearbox – Replacement of Comer Code TB-278C 1:1 provides a durable, efficient, and cost-effective solution for rotary tiller machinery. With a focus on reliability, precision, and performance, this gearbox helps improve operational efficiency and extends the life of your agricultural equipment.

| Description | Rotary Harrows Gearboxes, Rotary Tillers Gearboxes – Replacement of Comer Code TB-278C 1:1 |

|---|---|

| Application | Various (agricultural) applications, Mowers, Series mill |

| Consists of | Gearbox |

| Order Oil Separately | Technical Information |

| All technical data corresponds to ISO 6335 and ISO 281. | |

| Max. Input Power | 40.5 kW |

| Max. Output Torque | 695 Nm |

| Contains Oil | No |

| Max. Oil Capacity | 1.6 l |

| Oil SAE Viscosity Grade | 80W-90 |

| Weight | 24 kg |

| Gear Arrangement | 5 – 6 |

| Ratio | 1 : 1 |

| Input Shaft | Z |

| Shaft X | C |

| Shaft Z | 1 3/8″ (6) (A) |

Rotary Tillers Gearboxes – Replacement of Comer Code TB-278C 1:1

The Rotary Tillers Gearbox – Replacement of Comer Code TB-278C 1:1 is a high-performance, durable gearbox designed specifically for use in rotary tillers, offering an efficient solution for soil preparation and land cultivation. This replacement gearbox is engineered to deliver reliable power transmission from the tractor’s PTO to the tiller blades, ensuring smooth operation even in tough agricultural environments.

Key features of the TB-278C gearbox include a 1:1 gear ratio, which provides optimal power transfer for tilling operations, making it highly effective for various types of soil, from light to heavy-duty farming applications. The robust construction ensures resistance to wear and tear, extending the lifespan of the gearbox and reducing maintenance costs. Additionally, the gearbox is designed for easy installation, offering a direct replacement for the Comer TB-278C gearbox, minimizing downtime and ensuring continued productivity in the field.

The TB-278C gearbox is built with precision engineering and high-quality materials, making it a reliable choice for both small-scale farms and large agricultural operations. Its design allows for efficient energy transfer, which maximizes the performance of the tiller and enhances fuel efficiency.

This replacement gearbox is ideal for farmers seeking a high-quality, cost-effective solution to maintain the performance of their rotary tillers. Whether replacing a worn-out gearbox or upgrading an older model, the TB-278C ensures optimal tilling performance and increased productivity. The gearbox also benefits from rigorous quality control standards to meet the high demands of modern agriculture.

In summary, the Rotary Tillers Gearbox – Replacement of Comer Code TB-278C 1:1 provides a durable, efficient, and cost-effective solution for rotary tiller machinery. With a focus on reliability, precision, and performance, this gearbox helps improve operational efficiency and extends the life of your agricultural equipment.

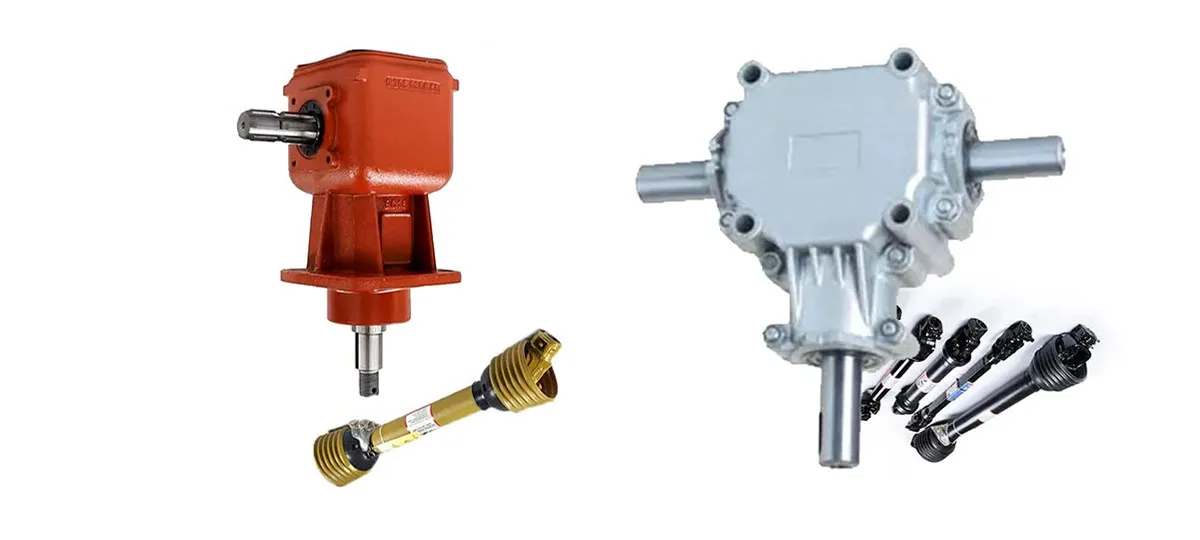

PTO Shafts for Rotary Tiller Gearboxes

PTO shafts for rotary tiller gearboxes are vital components in modern farming, providing the essential link between a tractor’s power take-off (PTO) system and the rotary tiller gearbox. These shafts are designed to transmit mechanical power from the tractor’s engine to the tilling mechanism, enabling the tiller blades to rotate and perform soil cultivation efficiently. By facilitating power transfer, PTO shafts ensure optimal tilling performance in various agricultural applications, from soil preparation to land maintenance.

Durability and reliability are key attributes of PTO shafts for rotary tiller gearboxes. Made from high-strength steel or other durable materials, these shafts are built to withstand the stresses of heavy-duty agricultural work. Whether in challenging terrain or harsh environmental conditions, PTO shafts are designed to deliver consistent, long-lasting performance, reducing the need for frequent maintenance and minimizing downtime during critical farming seasons.

Another significant feature of PTO shafts is their ease of attachment and detachment. These shafts are engineered for quick coupling to both the tractor and the tiller gearbox, ensuring seamless integration with various equipment models. The quick-connect mechanism allows farmers to easily switch between different implements, improving operational efficiency and reducing setup time when changing tasks or equipment.

Safety is also a top priority with PTO shafts for rotary tiller gearboxes. These shafts are equipped with protective guards, slip clutches, and other safety features designed to prevent accidents and minimize damage during operation. PTO shafts help ensure safe and secure connection between the tractor and tiller, reducing the risk of equipment failure or injury during operation, especially in high-torque conditions.

Finally, PTO shafts for rotary tiller gearboxes are highly customizable, offering a range of lengths, configurations, and designs to suit various tiller models and tractor types. Customization ensures that the PTO shaft is perfectly matched to the specific needs of each farm, maximizing the efficiency and performance of the rotary tiller. With the right PTO shaft, farmers can enhance their productivity, ensuring smooth and effective soil preparation for optimal crop growth.

About FMP

Based in Italy, FMP is a leading manufacturer known for its expertise in designing, developing, and producing high-performance gearboxes, primarily for the agricultural machinery sector. With a reputation built on precision engineering, innovation, and unmatched reliability, FMP consistently delivers superior products that meet the dynamic demands of the agricultural and industrial markets. Our extensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other key components, all tailored to provide customized solutions across a wide range of applications.

At FMP, we recognize that every client has unique requirements. This is why we specialize in delivering bespoke solutions, whether in the form of individual components or fully integrated systems. We collaborate closely with our customers to ensure each solution is not only effective but also efficient, ensuring maximum value. Our commitment to rapid, professional responses, along with expert guidance, guarantees that every inquiry is handled with precision and attention to detail.

We prioritize open communication and collaboration throughout the entire product development process. Our team works side-by-side with clients to fully understand their specific needs, providing insightful recommendations that lead to the most optimal solutions. Whether we are developing new products or fulfilling ongoing orders, we are committed to delivering high-quality, precision-engineered solutions with speed and reliability.

Quality is at the heart of everything we do. We adhere to the highest manufacturing standards and implement rigorous quality control processes to ensure every product not only meets but exceeds industry expectations. This unwavering commitment to quality, combined with our values of integrity, teamwork, and perseverance, has enabled us to build strong, enduring relationships with clients in over 30 countries around the world.

FMP is always open to cultivating global partnerships, providing expert advice, and offering tailored solutions to meet the diverse needs of our clients. We go beyond simply supplying products—we aim to foster long-term relationships that drive the success of each project. Whether you’re seeking innovative solutions for a new initiative or need ongoing support for existing systems, FMP is dedicated to addressing your technical challenges and helping ensure your continued success.

Author: CX