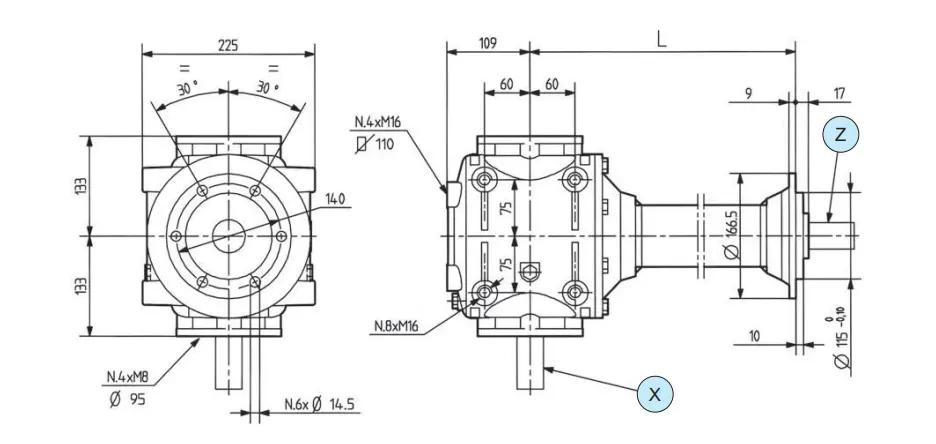

Rotary Tiller Gearbox TLZ-292A Specifications

| i | 1.86 |

| N1[rpm] | 540 |

| P1[kW] | 47.8 |

| M2[Nm] | 1525 |

Shaft X |

1” 3/8 Z6 |

Shaft Z |

42*48 |

| Input | X |

Features of the Rotary Tiller Gearbox TLZ292A

The Rotary Tiller Gearbox TLZ292A is designed to offer high performance, durability, and reliability for use in agricultural machinery, particularly in rotary tillers. Below are the key features of this gearbox:

Heavy-Duty Construction

The TLZ292A gearbox is built with a robust, heavy-duty design to withstand the demanding conditions of agricultural operations. It is constructed using high-quality materials that ensure longevity and superior resistance to wear, even under heavy workloads.

High Efficiency Transmission

The gearbox is engineered for optimal power transmission, ensuring efficient operation of the tiller blades. It provides smooth and consistent power flow, allowing for improved soil penetration and tilling performance. The high-efficiency design minimizes energy loss and enhances the overall productivity of the rotary tiller.

Compact and Lightweight Design

Despite its powerful performance, the TLZ292A gearbox boasts a compact and lightweight structure. This makes it easy to handle, install, and maintain, while also helping to reduce the overall weight of the tilling system for improved maneuverability and fuel efficiency.

Superior Heat Dissipation

The gearbox is equipped with a cooling system designed to maintain an optimal operating temperature. The enhanced heat dissipation mechanism ensures that the gearbox operates at peak performance for extended periods without overheating, thus improving the overall reliability and lifespan of the gearbox.

Adjustable PTO Shaft Compatibility

The TLZ292A gearbox is compatible with a variety of PTO shafts, allowing for easy integration with different tractor models. It features adjustable PTO input options, ensuring flexibility and compatibility with a wide range of agricultural machinery.

In summary, the Rotary Tiller Gearbox TLZ292A is a high-performance, durable, and reliable solution for agricultural tilling needs. Its efficient transmission, robust construction, and low maintenance requirements make it an excellent choice for farmers looking to enhance productivity and ensure long-term operational reliability.

Structural Components of the Rotary Tiller Gearbox TLZ292A

The Rotary Tiller Gearbox TLZ292A consists of several key structural components designed for durability, efficiency, and ease of use in demanding agricultural applications. Below is a description of the main components:

Input Shaft and PTO Connection

The input shaft of the TLZ292A gearbox is connected to the tractor’s power take-off (PTO) system. This component transmits power from the tractor’s engine to the gearbox, driving the rotary tiller’s blades. The PTO connection is designed for easy integration with different tractor models, offering flexibility and ensuring efficient power transfer to the gearbox.

Reduction Gears

The gearbox includes precision-engineered reduction gears that reduce the high-speed input from the PTO to a lower, more suitable speed for the tiller blades. These gears ensure that the tiller operates efficiently, providing the necessary torque for optimal soil penetration and tilling performance while minimizing energy loss.

Bearings and Bushings

To ensure smooth and reliable operation, the TLZ292A gearbox is equipped with high-quality bearings and bushings. These components reduce friction between moving parts, ensuring smooth gear transitions and preventing wear and tear. The durable bearings also extend the lifespan of the gearbox, enabling it to perform effectively under heavy-duty conditions.

Housing and Enclosure

The housing of the TLZ292A gearbox is made from high-strength materials to provide robust protection for the internal components. The durable housing safeguards the gearbox’s gears, shafts, and bearings from environmental elements like dust, dirt, moisture, and impact. Additionally, the housing features a corrosion-resistant coating, which enhances its durability and protects it from rust and other forms of damage.

Output Shaft and Tiller Blade Connection

The output shaft connects the gearbox to the rotary tiller’s blades. It is designed to transfer the reduced power from the gearbox to the tiller blades, driving them to rotate at the appropriate speed and torque. The output shaft’s design ensures reliable performance and efficient power transmission, contributing to the overall effectiveness of the tilling process.

The Rotary Tiller Gearbox TLZ292A features key structural components like the input shaft, reduction gears, bearings, housing, and output shaft, all working together to deliver high efficiency, reliability, and longevity in agricultural tilling applications.

Working Principle of the Tractor PTO Driven Rotary Tiller Gearbox

The working principle of the Tractor PTO Driven Rotary Tiller Gearbox revolves around efficiently transferring power from the tractor’s engine to the rotary tiller blades, allowing the machine to perform soil tilling operations. Here’s how the gearbox works in five key steps:

Power Transfer from Tractor PTO to Gearbox

The process begins when the tractor’s engine powers the PTO shaft (Power Take-Off), which is connected to the gearbox input shaft. The PTO shaft is designed to rotate at high speeds, typically ranging from 540 to 1000 RPM, depending on the tractor’s engine output. This rotational power is transferred directly to the gearbox, which serves as the intermediary mechanism between the tractor and the tiller blades.

Speed Reduction through Reduction Gears

Once the power enters the gearbox, it passes through a set of reduction gears. These gears reduce the high rotational speed of the PTO shaft to a much lower, more suitable speed for the tiller blades. The reduction gearing ensures that the blades operate at optimal speeds, providing the necessary torque for effective soil cutting and penetration.

Torque Amplification for Tilling Efficiency

The reduced speed from the gearbox is paired with an increase in torque, which is essential for tilling heavy or compacted soil. This increased torque enables the tiller blades to dig deeper into the ground, breaking up soil and aerating it effectively. The gearbox ensures the proper balance of speed and torque for maximum tilling efficiency, depending on the soil conditions.

Output Shaft Drives the Tiller Blades

The output shaft of the gearbox is connected to the rotary tiller blades. As the gearbox reduces the PTO input speed and increases torque, the output shaft rotates at a lower but more powerful speed. This rotation drives the blades of the tiller, causing them to spin and cut through the soil. The tiller blades are typically arranged in a spiral pattern, enabling them to cover the soil evenly and consistently.

Continuous Power Flow and Smooth Operation

The gearbox ensures a continuous flow of power from the tractor’s PTO to the tiller blades. The design of the gearbox helps maintain consistent operation, even under varying loads, by optimizing the distribution of power. It also minimizes energy loss, ensures smooth transitions between gears, and reduces wear on critical components, allowing the tiller to operate efficiently over extended periods.

The PTO driven rotary tiller gearbox works by transferring high-speed power from the tractor’s PTO, reducing and adjusting the speed and torque, and then delivering controlled power to the tiller blades for effective soil tilling. The gearbox’s role in optimizing speed, torque, and power flow is critical for the performance and durability of the rotary tiller.

About FMP

Headquartered in Italy, FMP is a leading manufacturer recognized for its expertise in designing, developing, and producing high-performance gearboxes, primarily for the agricultural machinery sector. Renowned for our precision engineering, innovation, and unwavering reliability, FMP has established itself as a trusted partner in meeting the evolving demands of both the agricultural and industrial markets. Our comprehensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other critical components, all designed to provide effective, customized solutions across a wide range of applications.

At FMP, we understand that every client has unique needs and challenges. This is why we specialize in offering tailored solutions, whether through individual components or fully integrated systems. We take a collaborative approach, working closely with our customers to ensure that each solution is not only effective but also efficient. Our commitment to fast, professional responses and expert guidance guarantees that every inquiry is handled with the utmost care and precision, ensuring the best outcomes for our clients.

We place a strong emphasis on open and ongoing communication, particularly in the development of new products. Our dedicated team works directly with clients to fully understand their requirements, offering valuable insights and recommendations that lead to optimal solutions. Whether we are designing innovative products or fulfilling existing orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time, ensuring that our clients receive the best service and results.

At the core of FMP’s operations is our relentless focus on quality. We adhere to the highest manufacturing standards, employing stringent quality control measures to ensure that every product not only meets but exceeds industry expectations. This commitment to quality, coupled with our core values of integrity, teamwork, and perseverance, has allowed us to build lasting, trusting relationships with customers in nearly 30 countries around the world.

FMP is always eager to build global partnerships and remains dedicated to providing expert guidance and custom solutions to meet the diverse needs of our clients. Our approach goes beyond merely delivering products; we aim to cultivate long-term relationships that contribute to the success of every project. Whether you require innovative solutions for a new venture or ongoing support for an existing system, FMP is here to address your technical challenges and help ensure your sustained success.

Author: CX