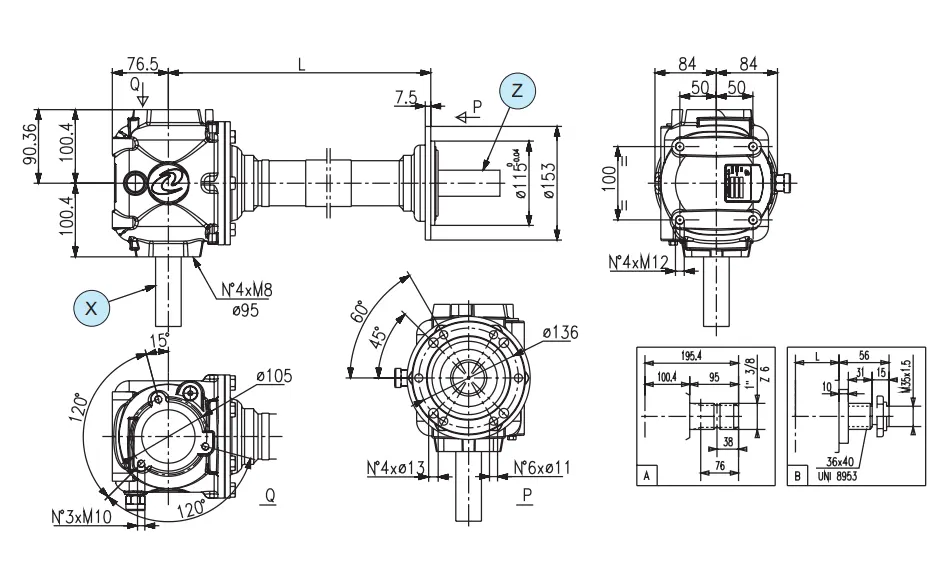

Rotary Tiller Gearbox TLZ-21J Specifications

| i | 1.46 |

| N1[rpm] | 540 |

| P1[kW] | 29.4 |

| M2[Nm] | 736 |

Shaft X  |

1” 3/8 Z6 |

Shaft Z  |

36*40 |

| Input | X |

How Does the Tractor PTO Driven Rotary Tiller Gearbox Work?

The tractor PTO-driven rotary tiller gearbox works by transferring mechanical power from the tractor’s power take-off (PTO) shaft to the rotary tiller’s blades, enabling efficient soil cultivation. When the tractor is in motion, the PTO shaft spins, transmitting rotational energy to the gearbox, which then distributes this power to the tiller blades. These blades, often designed in a set of rotating discs or tines, dig into the soil, breaking it up into smaller particles for better aeration and seedbed preparation.

The gearbox plays a critical role in ensuring that the rotational speed and torque provided by the PTO shaft are appropriately converted and distributed to the tiller blades. The gearbox typically includes a series of gears and shafts designed to adjust the speed and force, providing optimal conditions for different soil types and cultivation depths. This enables the rotary tiller to operate efficiently under various agricultural conditions.

The gearbox also helps to maintain a consistent rotation speed, ensuring smooth operation and preventing the tiller blades from overloading. The torque provided by the PTO is transmitted through the gearbox, which reduces the risk of damage to both the PTO shaft and the tiller itself. As a result, the gearbox helps extend the service life of both the tractor and the tiller.

In addition to power transmission, the gearbox is designed to handle the challenging conditions that rotary tillers face during use, such as resistance from tough soil or rocks. High-quality materials, robust design, and proper lubrication ensure that the gearbox can endure the stresses of operation without failure. Periodic maintenance, such as oil changes and inspections, is essential to keeping the gearbox in optimal working condition.

Overall, the tractor PTO-driven rotary tiller gearbox is essential for converting the engine power from the tractor into the necessary force to drive the tiller blades. By regulating speed, torque, and efficiency, it ensures that the rotary tiller can perform effectively and with minimal wear, maximizing productivity in the field.

Application of Tractor PTO Driven Rotary Tiller Gearbox

The tractor PTO-driven rotary tiller gearbox is a crucial component in modern agriculture, enabling efficient soil preparation and cultivation. Its primary application is in rotary tillers used for tilling and loosening soil, making it ideal for various farming tasks, from preparing seedbeds to incorporating organic matter into the soil. Below are key areas where the tractor PTO-driven rotary tiller gearbox is applied:

- Soil Tillage and Seedbed Preparation

One of the primary applications of the tractor PTO-driven rotary tiller gearbox is soil tillage. By transferring power from the tractor’s PTO to the rotary tiller blades, the gearbox enables the blades to cut into and break up compacted soil. This process helps prepare the soil for planting by ensuring proper aeration and breaking down clumps of earth, making it easier for seeds to germinate and take root. - Weed Control

Rotary tillers equipped with PTO-driven gearboxes are also widely used for weed control. By turning over the soil and disturbing the root systems of weeds, these tillers help eliminate unwanted vegetation and prevent it from regrowing. The gearbox ensures that the tiller blades operate at the right speed and torque to efficiently uproot weeds without damaging the surrounding soil structure. - Incorporating Organic Matter and Fertilizers

Another significant application of the PTO-driven rotary tiller gearbox is the incorporation of organic matter (such as crop residue, compost, or manure) into the soil. The rotary tiller blades mix the organic material into the topsoil, enhancing soil fertility and improving its structure. This process also helps accelerate decomposition, enriching the soil with essential nutrients for future crops. - Breaking up Hard Pan Soil

In areas with compacted soil, a PTO-driven rotary tiller gearbox can be invaluable for breaking up hardpan layers. Hardpan is a dense, impenetrable layer beneath the soil surface that restricts root growth and water infiltration. The gearbox ensures that the tiller blades have the necessary power to break through these tough layers, facilitating better root penetration and improving the soil’s overall water retention. - Land Clearing and Site Preparation

In addition to traditional tilling, the PTO-driven rotary tiller gearbox is also applied in land clearing and site preparation for agricultural or construction purposes. The tiller can clear vegetation, break up rocky or uneven terrain, and prepare large areas for planting or construction. The gearbox provides the necessary power to operate the tiller blades at high speeds, allowing for effective land clearing even in challenging conditions.

The tractor PTO-driven rotary tiller gearbox is an essential tool for a wide range of agricultural applications. It helps improve soil quality, enhance crop yields, and increase operational efficiency by ensuring optimal power transmission for various tasks like tillage, weed control, and land preparation.

About FMP

Headquartered in Italy, FMP stands as a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, with a primary focus on the agricultural machinery sector. Known for our commitment to precision engineering, innovation, and unparalleled reliability, FMP has earned a solid reputation for delivering premium products that meet the dynamic needs of both agricultural and industrial markets. Our extensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and other essential components, all tailored to provide bespoke solutions across a wide range of applications.

At FMP, we recognize that every client faces distinct challenges and requirements. That’s why we specialize in providing customized solutions, whether it’s individual components or complete, integrated systems. We work in close partnership with our customers, ensuring that every solution is not only effective but also efficient, optimizing performance and value. Our commitment to swift, professional responses, combined with expert guidance, ensures that each inquiry is managed with precision and care.

We prioritize clear and ongoing communication, particularly when developing new products. Our dedicated team works directly with clients to gain a deep understanding of their specific needs, offering practical insights that lead to the most optimal solutions. Whether we are designing cutting-edge products or fulfilling ongoing orders, we remain steadfast in our commitment to delivering high-quality, precision-engineered solutions with speed and reliability.

At the heart of FMP’s operations is an unwavering focus on quality. We adhere to the highest manufacturing standards, incorporating stringent quality control procedures to ensure that every product not only meets but exceeds industry expectations. Our dedication to quality, paired with our core values of integrity, collaboration, and persistence, has helped us forge strong, long-term relationships with customers in over 30 countries worldwide.

FMP is always open to fostering global partnerships and remains dedicated to offering expert advice and tailored solutions to meet the diverse needs of our clients. We go beyond merely supplying products—we strive to build lasting, meaningful relationships that drive the success of every project. Whether you’re looking for innovative solutions for a new initiative or ongoing support for an existing system, FMP is here to address your technical challenges and ensure your continued success.

Author: CX