Specifications of Rotary Tiller Gearbox TB-22C

| Description |

Rotary Tiller Gearboxes – Replacement of Comer Gearbox TB-22C

|

|---|---|

| Application |

|

| Consists of |

|

| Technical information |

|

| Contains oil |

No

|

| Capacity and oil type |

3,3 GL-5 80W-90 l

|

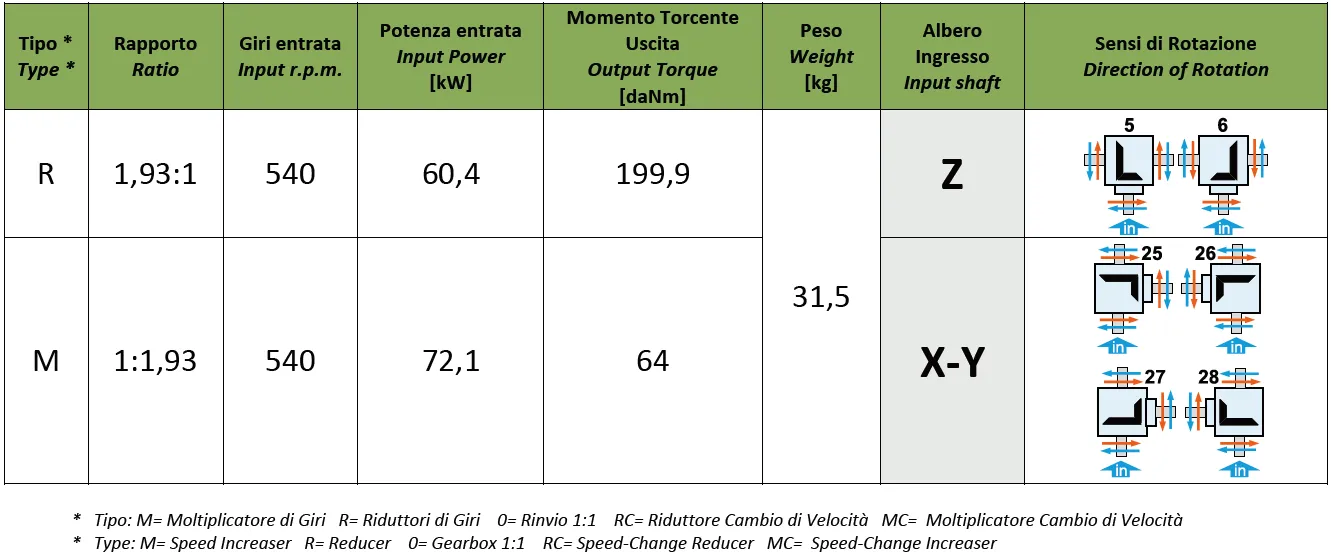

| Gear arrangement Increasing |

23 – 24

|

| Gear arrangement Reducing |

3 – 4

|

| Input power kW / HP Increasing |

72.1 / 98 kW/HP

|

| Input |

540 r/min

|

| Input shaft Increasing |

Y

|

| Input shaft Reducing |

Z

|

| Material housing |

Cast iron GG25

|

| Input power KW / HP Reducing |

60.4 / 82 kW/HP

|

| Output Torque DaNm |

199.9 daNm

|

| Output Torque DaNm Increasing |

64 daNm

|

| Oil |

500 h

|

| Ratio Increasing |

1: 1.93

|

| Ratio Reducing |

1.93: 1

|

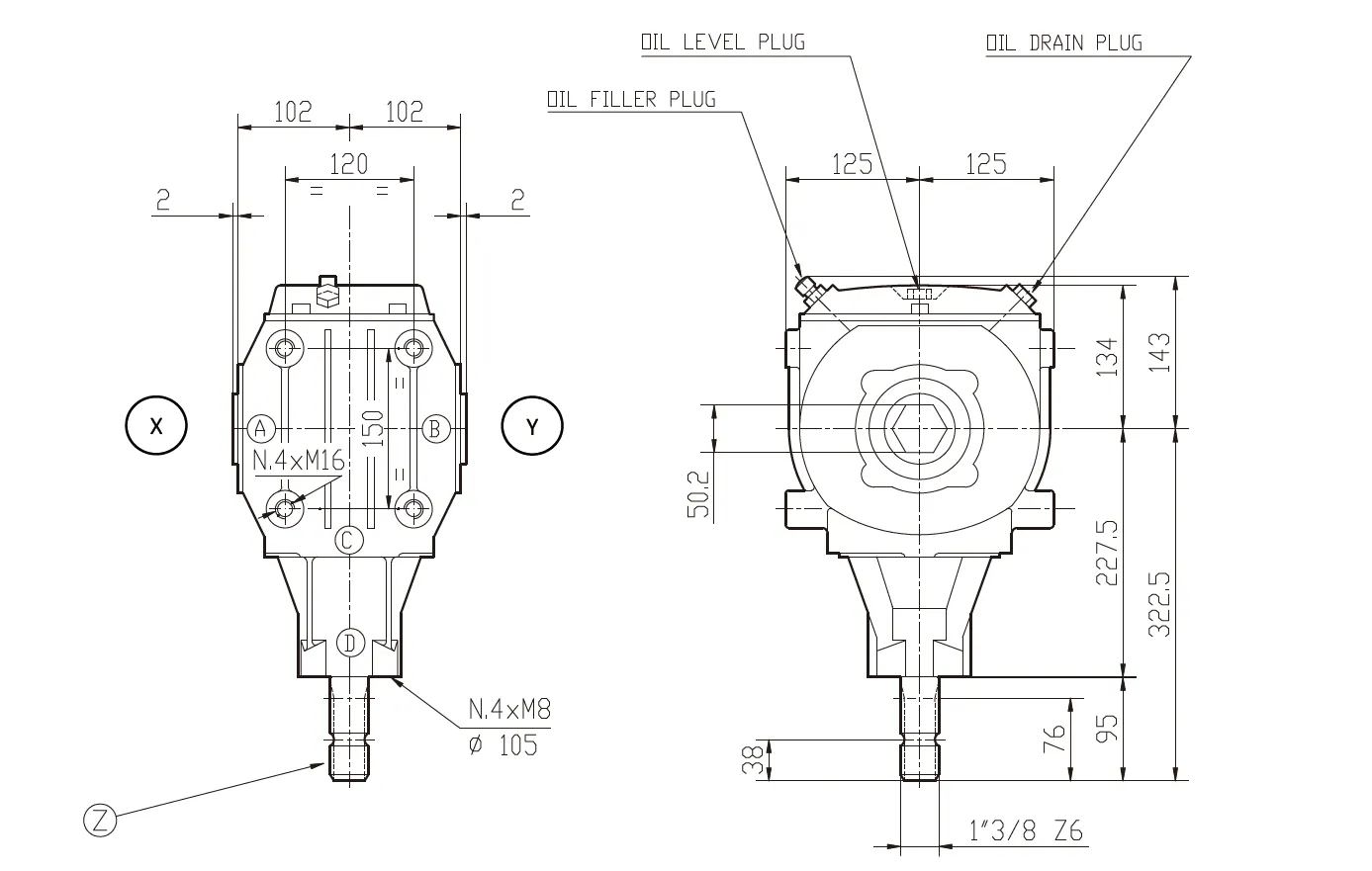

| Shaft Y |

1 3/8″ (6) (B)

|

| Shaft Z |

1 3/8″ (6) (D)

|

| Weight |

31.5 kg

|

How Does the Rotary Tiller Gearbox Work?

The rotary tiller gearbox plays a critical role in the operation of a rotary tiller, converting the power supplied by a tractor’s PTO (Power Take-Off) system into the rotational force needed to drive the tilling blades. It is an essential component in ensuring the smooth and efficient functioning of the tiller, enabling it to break up soil for agricultural purposes. The gearbox receives power from the tractor’s PTO shaft and transfers this energy through its internal gearing system to the rotating blades.

The primary function of the rotary tiller gearbox is to adjust the speed and direction of the blades. The gearbox typically includes a set of gears that allow the operator to control the rotation of the blades at different speeds, depending on the specific requirements of the soil being worked. By selecting the appropriate gear ratio, the gearbox enables the tiller to work effectively in various soil types, from soft and loose soil to harder, compacted ground.

In addition to controlling blade speed, the rotary tiller gearbox also helps distribute the power evenly across the tilling blades, ensuring consistent performance throughout the tilling process. This is crucial for achieving uniform soil depth and texture, which is important for optimizing soil aeration and preparing it for planting. The design of the gearbox allows it to withstand the intense forces generated during operation while maintaining durability and reliability over time.

The gearbox is typically constructed from high-quality materials to handle the heavy stress and harsh conditions of tilling operations. It is essential for the gearbox to be properly lubricated to reduce friction and prevent wear. Regular maintenance, such as oil changes and inspections, is crucial to ensure the gearbox continues to operate at peak efficiency and to avoid any potential failures during use.

Overall, the rotary tiller gearbox is a vital component that ensures the effective transfer of power from the tractor to the tilling blades. By adjusting blade speed, distributing power evenly, and maintaining durability, the gearbox enables farmers and landscapers to efficiently prepare soil for planting, promoting healthier crops and improving land productivity.

Rotary Tiller Gearbox Oil Change Procedure

Regular oil changes are crucial to maintaining the efficiency and longevity of rotary tiller gearboxes. Below is a step-by-step guide for performing an oil change:

- Preparation: Ensure that the rotary tiller gearbox is cool before starting the procedure. Gather all necessary tools, including an adjustable wrench or socket, and the recommended type and amount of oil. Wear protective gloves and clothing to avoid contact with hot components and oil.

- Drain Plug Removal: Locate the drain plug on the bottom of the gearbox. Using the appropriate tool, carefully remove the plug to allow the oil to drain into a suitable container. Ensure the container is large enough to hold all the used oil.

- Inspection of Old Oil: As the oil drains, visually inspect its condition. If the oil appears milky, has a burnt odor, or contains metal shavings, it indicates contamination or excessive wear, and the oil should be replaced completely. Otherwise, proceed to the next step.

- Refilling: Once the oil has completely drained, replace the drain plug securely. Then, refill the gearbox with fresh oil. Be sure to refer to the user manual for the correct oil type, grade, and viscosity for your specific rotary tiller model.

- Verification and Testing: After refilling, check the oil level using a dipstick, if available. Add more oil if necessary to reach the correct level. Once the oil is properly filled, turn the gearbox by hand or run it briefly to circulate the oil and ensure it fully coats the internal components.

- Final Inspection: After running the gearbox for a short period, recheck the oil level. If necessary, add more oil to ensure the gearbox is properly lubricated.

Regular oil changes are essential to keep the rotary tiller gearbox operating efficiently. By following these steps and using the correct oil type, you can ensure optimal performance and extend the lifespan of your equipment. It is recommended to perform oil changes at regular intervals as specified by the manufacturer.

PTO Shaft and Rotary Tiller Gearboxes

A PTO (Power Take-Off) shaft is a critical component that connects a tractor’s engine to a rotary tiller gearbox. By transferring mechanical power from the tractor’s PTO to the tiller, the shaft enables the rotary tiller to perform its soil cultivation tasks. The PTO shaft is designed to handle the torque and rotational force required to drive the tiller’s working mechanism, ensuring efficient operation.

The rotary tiller gearbox, on the other hand, plays a crucial role in regulating the speed and torque of the PTO shaft’s power output. Once the power is transferred from the tractor, the gearbox adjusts it to the appropriate level for the rotary tiller’s blades, ensuring the right rotational speed for effective tilling. These gearboxes are engineered to withstand the demanding conditions of soil tilling, including high torque and heavy-duty use.

The interaction between the PTO shaft and rotary tiller gearbox is essential for optimal performance. The PTO shaft’s design allows it to handle rotational motion and force, while the gearbox ensures that this power is appropriately adapted for the rotary tiller’s needs. This seamless collaboration ensures smooth operation, reducing wear and tear on components and improving the overall efficiency of tilling operations.

Regular maintenance of both the PTO shaft and the rotary tiller gearbox is crucial for their longevity and performance. Proper lubrication, periodic oil changes for the gearbox, and inspections for wear or damage on the PTO shaft can prevent costly breakdowns and extend the lifespan of the equipment. Ensuring both components are in top condition maximizes efficiency during use, making them essential parts of any farming or agricultural machinery fleet.

The PTO shaft and rotary tiller gearbox are vital components for efficient tilling operations. Their complementary roles ensure that the tractor’s power is effectively transferred and adjusted to the needs of the tiller, providing farmers with the necessary tools to perform heavy-duty soil cultivation with minimal downtime and maximum reliability. Proper care and maintenance of these components are essential to maintain high performance and avoid unnecessary repairs.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer renowned for its expertise in the design, development, and production of high-performance gearboxes, primarily catering to the agricultural machinery industry. Known for precision engineering, innovation, and unparalleled reliability, FMP delivers superior products that address the evolving demands of both the agricultural and industrial sectors. Our extensive product range includes specialized gearboxes for lawn mowers, PTO shafts, and a variety of essential components, all engineered to provide tailored solutions for diverse applications.

At FMP, we understand that each customer has distinct needs and challenges. This is why we specialize in delivering custom solutions, whether for individual components or fully integrated systems. We work closely with our customers, ensuring each solution is both effective and efficient, providing maximum value. Our commitment to quick, professional responses, coupled with expert guidance, ensures that every inquiry is handled with meticulous care and precision.

We place great importance on fostering open communication and collaboration throughout the product development process. Our team works directly with clients to fully comprehend their specific requirements, offering valuable insights that result in the most optimal solutions. Whether developing new products or fulfilling ongoing orders, FMP is committed to delivering high-quality, precision-engineered solutions with speed and reliability.

Quality is at the core of everything we do at FMP. We adhere to the highest manufacturing standards and implement stringent quality control processes to ensure that every product not only meets but exceeds industry expectations. This dedication to quality, along with our values of integrity, teamwork, and perseverance, has allowed us to build strong, lasting relationships with clients in more than 30 countries worldwide.

FMP is always open to forging global partnerships, providing expert advice, and delivering customized solutions to meet the diverse needs of our clients. We aim to build long-term relationships, not merely supply products. Whether you need innovative solutions for a new project or ongoing support for an existing system, FMP is dedicated to addressing your technical challenges and ensuring your continued success.

Author: CX