|

|

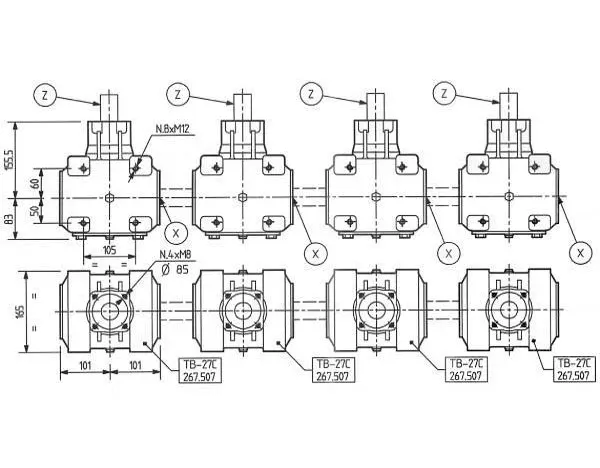

Specifications of Rotary Tiller Gearbox TB-27C

|

|

| Description |

Rotary Tiller Gearbox – Replacement of Comer Gearbox TB-27C

|

|---|---|

| Application |

|

| Consists of |

|

| Technical information |

|

| Max. input power |

40.5 kW

|

| Max. output torque |

693 nm

|

| Contains oil |

No

|

| Max. oil capacity |

1.1 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GG25

|

| Weight |

39.5 kg

|

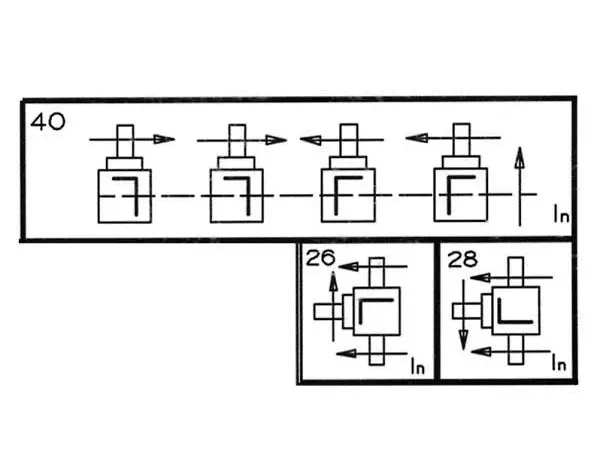

| Gear arrangement |

26

|

| Ratio |

1:1

|

| Input shaft |

Z

|

| Shaft X |

1 3/8″ (6) (C)

|

| Shaft Z |

1 3/8″ (6) (A)

|

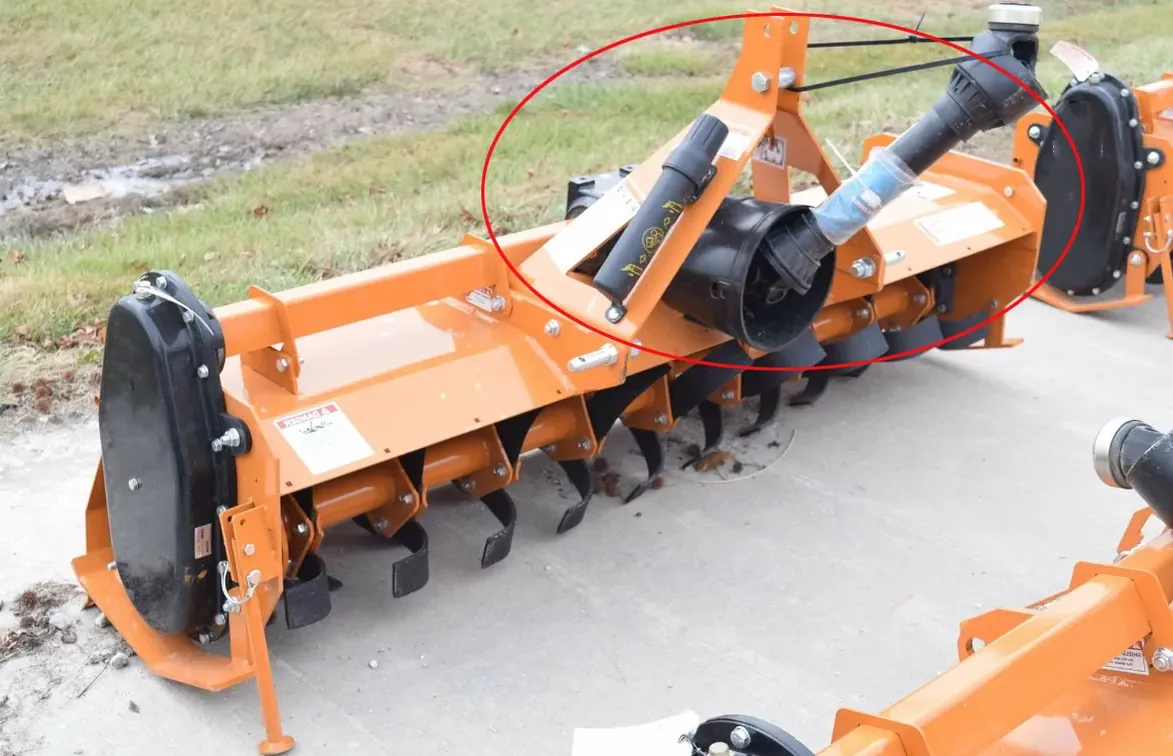

Rotary Tiller Gearbox TB-27C

The Rotary Tiller Gearbox TB-27C is a high-performance, durable gearbox designed for use in rotary tillers, providing efficient power transmission from the tractor to the tiller blades. Engineered with precision, it allows for smooth and reliable operation, ensuring that the tilling process is completed with consistency and minimal downtime. The TB-27C gearbox is built to handle demanding agricultural tasks, making it suitable for a variety of soil types and field conditions.

One of the key features of the TB-27C gearbox is its robust construction, which ensures longevity and reliability under heavy-duty use. The gearbox is crafted from high-quality materials, which can withstand the stress of continuous operation, reducing the need for frequent maintenance and extending its service life. This durability provides long-term cost savings by minimizing repairs and replacements.

The TB-27C gearbox is designed for easy integration with various rotary tiller models, offering flexibility and versatility. Its compatibility with different tilling equipment allows users to efficiently manage soil preparation in a range of agricultural settings, from small gardens to large-scale farming operations. The gearbox delivers consistent performance, whether used for light soil aeration or heavy-duty tilling in compacted or rocky soil.

In addition to its strength and versatility, the TB-27C gearbox is engineered to optimize fuel efficiency by ensuring smooth and steady power transfer from the tractor. This efficiency reduces fuel consumption, lowering operational costs for farmers and enhancing productivity. The combination of durability, efficiency, and versatility makes the TB-27C an essential component for achieving optimal soil cultivation and improving farming operations.

The Rotary Tiller Gearbox offers a range of benefits for agricultural and horticultural applications, making it an essential component for efficient soil cultivation. Here are some key advantages:

Enhanced Soil Tillage Efficiency

The rotary tiller gearbox is designed to efficiently transfer power from the tractor’s engine to the tiller’s rotating blades or tines. This allows the tiller to break up and loosen the soil more effectively, ensuring uniform soil aeration and a better seedbed for planting. The gearbox enables consistent performance, even in tough soil conditions, which helps reduce labor time and increases overall productivity.

Durability and Longevity

A well-constructed rotary tiller gearbox is built to withstand the harsh demands of agricultural operations. Made with durable materials and precision engineering, these gearboxes are designed to last under heavy load conditions, ensuring reliable performance over time. The robust construction minimizes the need for frequent repairs or replacements, providing a long service life and a high return on investment for farmers.

Versatility Across Different Soil Types

The rotary tiller gearbox is versatile and can be adapted for use with different types of soil, whether it’s compacted ground, rocky terrain, or softer soil. This flexibility makes it an ideal tool for diverse agricultural tasks such as field preparation, garden tilling, or land reclamation. The gearbox’s ability to efficiently adjust to varying conditions ensures optimal performance across a wide range of farming applications.

Smooth Power Transfer

The gearbox ensures smooth and reliable power transfer from the tractor to the tiller blades. This reduces the risk of stalling or inefficiencies in power delivery, providing steady, consistent performance throughout the tilling process. The smooth power transfer also reduces vibrations and wear on the equipment, enhancing the operator’s comfort and prolonging the lifespan of the machinery.

Reduced Maintenance Costs

With proper maintenance, rotary tiller gearboxes can minimize downtime and reduce overall maintenance costs. Regular lubrication, timely inspections, and proper handling ensure the gearbox continues to perform at its best, preventing costly repairs or premature replacements. Additionally, the efficient operation of the gearbox reduces strain on the entire tilling system, which translates into less wear and tear on other components.

In summary, the rotary tiller gearbox enhances soil preparation by improving efficiency, durability, versatility, and cost-effectiveness. Whether you’re working on small gardens or large agricultural fields, investing in a high-quality rotary tiller gearbox is a smart decision for ensuring the long-term success and sustainability of your farming operations.

PTO Shaft for Rotary Tiller Gearbox

A Power Take-Off (PTO) shaft is an essential component that connects a rotary tiller gearbox to a tractor, transmitting power from the tractor’s engine to the tiller’s gearbox. This connection enables the tiller to operate efficiently, driving the rotary blades or tines that till the soil, preparing the ground for planting. The PTO shaft ensures smooth and reliable power transfer, making it a critical part of any tilling operation.

The design of the PTO shaft for rotary tiller gearboxes typically consists of an input yoke, a drive shaft, and an output yoke. These components work together to facilitate a stable connection between the tractor and the tiller. The PTO shaft is designed to be easily attached or detached, allowing for quick and convenient use in various agricultural tasks. Depending on the application, PTO shafts come in different lengths and configurations to suit specific tractors and tiller models.

One of the key features of a PTO shaft is its ability to withstand the rigors of agricultural work. Built to endure heavy loads, high torque, and continuous operation in demanding environments, the PTO shaft is constructed with durable materials that ensure long-lasting performance. Regular maintenance is important to ensure the shaft operates at its peak performance and to prevent damage or wear that could compromise the efficiency of the entire tilling system.

For optimal performance, it’s crucial that the PTO shaft is properly maintained. This includes routine checks for wear, lubrication, and ensuring that all connections are secure. It’s also essential to ensure that the PTO shaft is the correct size and specification for the tractor and rotary tiller gearbox it is being used with. Proper adjustments and care can extend the life of the PTO shaft and prevent downtime during critical farming operations.

FMP offers a wide range of high-quality PTO shafts specifically designed for rotary tiller gearboxes. Our PTO shafts are built to meet industry standards, ensuring compatibility with various tractor models and tiller gearboxes. We provide customized solutions to meet specific agricultural needs, offering products that deliver efficient, reliable, and safe performance. Whether you need a replacement or a custom-built PTO shaft, FMP has the right solution for your farming equipment.

|

|

About FMP

Headquartered in Italy, FMP is a leading manufacturer with a distinguished reputation in the design, development, and production of high-performance gearboxes, primarily serving the agricultural machinery sector. Renowned for our commitment to precision engineering, innovation, and unparalleled reliability, FMP has earned a reputation for delivering superior products that meet the evolving demands of both the agricultural and industrial industries. Our comprehensive product portfolio includes specialized gearboxes for lawn mowers, PTO shafts, and a wide range of critical components, all designed to provide customized solutions across diverse applications.

At FMP, we recognize that each client faces unique challenges. That’s why we excel in delivering tailor-made solutions, whether for individual components or fully integrated systems. By working closely with our clients, we ensure that each solution is not only effective but also efficient. Our dedication to fast, professional responses, coupled with expert guidance, guarantees that every inquiry is met with the highest level of attention and precision.

We place a strong emphasis on transparent, ongoing communication, especially during the development of new products. Our team works directly with clients to fully understand their specific needs and provide valuable insights, ensuring optimal solutions are achieved. Whether we are designing innovative products or fulfilling ongoing orders, we are committed to delivering high-quality, precision-engineered solutions with speed and reliability.

At the core of FMP’s operations is an unwavering commitment to quality. We adhere to the highest manufacturing standards, implementing stringent quality control measures to ensure that every product meets or exceeds industry expectations. This relentless focus on quality, combined with our core values of integrity, teamwork, and perseverance, has enabled us to foster strong and lasting relationships with customers in nearly 30 countries worldwide.

FMP is always open to building global partnerships, offering expert advice and custom solutions to meet the diverse needs of our clients. Our approach goes beyond merely supplying products—we focus on cultivating long-term relationships that ensure the success of every project. Whether you require innovative solutions for a new initiative or ongoing support for an existing system, FMP is dedicated to addressing your technical challenges and ensuring your continued success.

Author: CX

Benefits of Using the Rotary Tiller Gearbox

Benefits of Using the Rotary Tiller Gearbox