Specifications of Rotary Rake Gearbox K-789C

| Product Description |

Rotary Rake Gearbox – Replacement of Comer Gearbox K-789C

|

|---|---|

| Product details |

|

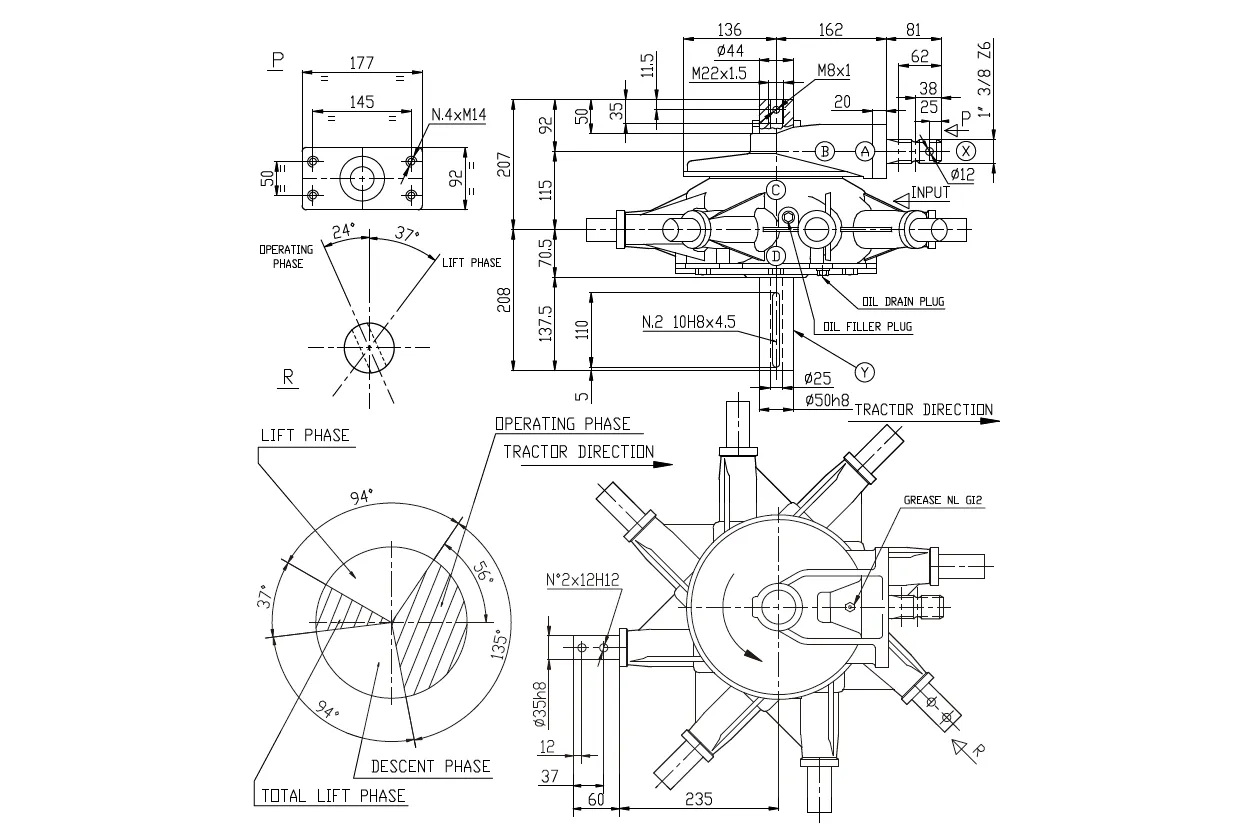

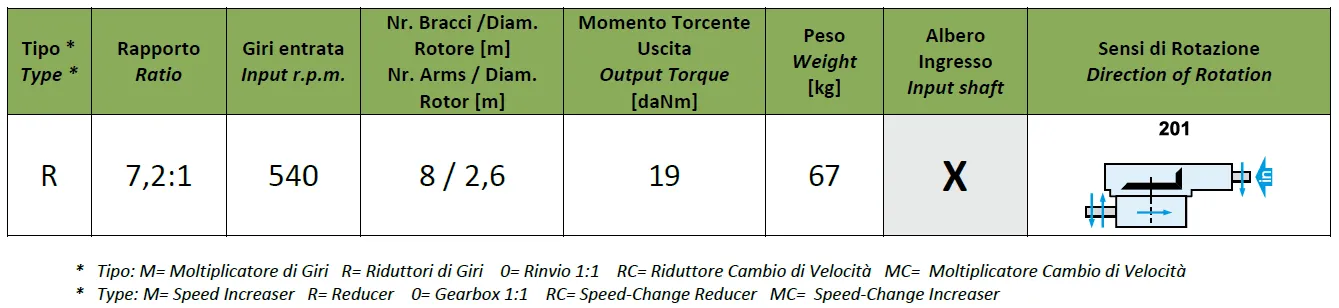

| Model |

K-789C

|

| Max. output torque |

190 nm

|

| Suitable for machine/vehicle brand |

|

| Contains oil |

No

|

| Oil SAE viscosity grade |

90EP

|

| Number of arms |

8

|

| Gear ratio |

7,2:1

|

| Input shaft |

1 3/8 Z6

|

| Shaft type |

1 x 1.3/8 (Z6)

|

Features of Rotary Rake Gearbox K-789C

The Rotary Rake Gearbox K-789C is a high-performance, precision-engineered component designed for agricultural machinery, specifically for rotary rakes. Below are the key features that make it an ideal choice for farmers and agricultural businesses:

- Durable Construction

The K-789C gearbox is built using high-quality materials that ensure robustness and long-lasting performance under demanding field conditions. Its durable construction is designed to withstand heavy loads and harsh environments. - Efficient Power Transmission

Featuring advanced gear design and precision machining, the K-789C ensures efficient power transmission from the tractor to the rake mechanism. This results in improved operational efficiency, reduced fuel consumption, and enhanced performance. - Compact Design

The compact and space-saving design of the K-789C gearbox allows it to fit seamlessly into rotary rake systems without compromising on strength or performance. Its streamlined design enhances the overall efficiency and usability of the rake. - High Torque Capacity

Designed to handle high torque, the K-789C is capable of transmitting the necessary power for the effective operation of large rotary rakes. This ensures that it can manage tough field conditions, such as dense crop material or challenging terrain. - Smooth and Quiet Operation

The precision gears within the K-789C gearbox are designed to ensure smooth and quiet operation, which reduces wear and tear and minimizes noise during operation. This contributes to a more comfortable working environment for the operator.

These features make the Rotary Rake Gearbox K-789C an essential component for improving the performance, durability, and efficiency of rotary rake machines used in agricultural processes.

|

|

|

Where Are Rotary Rake Gearboxes Used?

Rotary rake gearboxes are vital components in agricultural machinery, particularly in the haymaking and grass raking processes. Their primary function is to transmit power from the tractor’s PTO (Power Take-Off) shaft to the rotary rake, which is used to gather and organize hay, straw, or grass into windrows for easier harvesting or drying. Below are the key applications and areas where rotary rake gearboxes are used:

1. Haymaking

- Rotary Rakes: Rotary rake gearboxes are commonly used in rotary rakes that gather cut hay into windrows. The gearbox transmits power from the tractor to the rake’s rotating arms, allowing the rake to efficiently gather hay and form neat, evenly spaced windrows.

- Drying and Collection: In the haymaking process, the gearboxes help optimize the turning and gathering of hay, enabling quick and even drying, which is essential for high-quality hay production.

2. Grassland and Forage Management

- Forage Raking: Forage harvesters use rotary rake gearboxes to gather various types of forage like alfalfa, clover, and grass for silage or feed. The gearbox helps in efficient raking, ensuring that the grass or forage is evenly distributed into windrows for proper drying or baling.

- Silage Preparation: In silage preparation, rakes are used to move chopped forage into rows for easy collection by balers or forage harvesters, and the gearbox ensures smooth power transfer for continuous operation.

3. Straw Management

- Post-Harvest Straw Collection: After cereal crops like wheat, barley, and oats are harvested, rotary rake gearboxes are used in the rakes to gather the remaining straw into manageable windrows. The gearboxes ensure that the rake operates smoothly and efficiently during this crucial stage of crop management.

- Field Clean-Up: In addition to raking straw, rotary rake gearboxes are used in field clean-up operations, ensuring that all residues are collected effectively, leaving the soil ready for the next crop cycle.

4. Baling

- Windrow Formation for Baling: In the baling process, rotary rakes with rotary rake gearboxes are employed to gather hay, straw, or forage into windrows of a suitable size for baling. The gearboxes transmit power from the tractor to the rake’s tines, ensuring the correct formation of windrows that are ideal for subsequent baling by round or square balers.

- Preventing Losses: A well-formed windrow is essential to minimize losses during baling. The gearbox ensures that the rake operates efficiently to create the right windrow shape for easy pickup by balers.

5. Landscape and Agricultural Maintenance

- Crop Residue Management: Rotary rakes with gearboxes are used to collect crop residues such as leaves, grass, or small branches, helping in the preparation of fields for new crops. This function is important in both small-scale and large-scale farming operations.

- Soil Erosion Control: By efficiently managing the distribution of organic matter such as grass clippings or crop residues, rotary rakes with gearboxes can contribute to minimizing soil erosion, enhancing the soil’s nutrient content.

In summary, rotary rake gearboxes play a crucial role in the haymaking, grass raking, forage management, straw management, baling, and landscape maintenance processes. They are used in various agricultural and land management applications to help gather, distribute, and collect crop residues, hay, grass, and other organic materials, improving operational efficiency and ensuring optimal performance.

PTO Shaft for Rotary Rake Gearbox

A PTO (Power Take-Off) shaft is a key component used to transfer mechanical power from a tractor to agricultural machinery, such as rotary rakes. The PTO shaft plays an essential role in connecting the tractor’s power output system to the rotary rake gearbox, allowing the rotary rake to function properly. Here’s a breakdown of the significance and function of the PTO shaft in the rotary rake gearbox system:

1. Power Transmission

- Power Source: The PTO shaft is designed to transmit power from the tractor’s engine to the rotary rake gearbox. When the tractor is engaged, the PTO shaft turns, sending rotational energy to the gearbox. This rotation is then transferred to the rake’s rotating arms, allowing the rake to gather hay, straw, or grass into windrows.

- Efficiency: By efficiently transferring power from the tractor’s engine, the PTO shaft ensures that the rotary rake operates with high efficiency, reducing the amount of time and energy required to complete the raking process.

2. Adaptability

- Universal Fit: PTO shafts are typically designed to fit a variety of agricultural machinery, including rotary rakes, making them versatile and adaptable. The PTO shaft for a rotary rake gearbox is available in various sizes and designs, depending on the type of tractor and machinery.

- Custom Lengths: PTO shafts can be custom-made or adjusted for specific lengths to ensure optimal performance and proper engagement between the tractor and the rotary rake gearbox.

3. Heavy-Duty Construction

- Durability: The PTO shaft for rotary rake gearboxes is built with durability in mind. It is constructed to withstand the constant rotational stress and the impact of heavy agricultural tasks. Materials like high-strength steel or alloy metals are commonly used to prevent wear and ensure longevity, even under demanding operating conditions.

- Reliability: PTO shafts must be able to handle varying loads, including the torque produced by the rotary rake gearbox. With proper maintenance, the PTO shaft provides reliable performance over many seasons of use.

4. Safety Features

- Shielding: Many PTO shafts come equipped with a safety shield to prevent accidental contact with rotating parts, reducing the risk of injury during operation. Safety features like slip clutches and overrun devices can also be integrated into the PTO shaft for added protection.

- Quick Connect: PTO shafts often feature a quick-connect coupling that enables fast and safe attachment to the tractor and rotary rake. This minimizes downtime during equipment setup and increases operational efficiency.

5. Versatility

- Multiple Applications: While the primary use of the PTO shaft in rotary rakes is to transfer power to the gearbox, PTO shafts can also be used in a wide range of other agricultural applications. These include operating mowers, tillers, balers, and other PTO-driven equipment.

- Seasonal Versatility: PTO shafts for rotary rake gearboxes are often used seasonally, typically during haymaking or forage gathering. However, they can be adapted for use with other equipment for tasks such as silage harvesting or straw management.

The PTO shaft is a critical link in the power transmission chain between the tractor and the rotary rake gearbox, ensuring that the rake operates efficiently and reliably. By transmitting power effectively, the PTO shaft enhances the overall performance of the rotary rake, optimizing the raking process and helping agricultural operations achieve higher productivity. Its versatility, durability, and safety features make it an essential component in modern agricultural machinery.

About FMP

Headquartered in Italy, FMP is a leading manufacturer specializing in the design, development, and production of high-performance gearboxes, with a primary focus on the agricultural machinery sector. Renowned for our precision engineering, innovative solutions, and unwavering reliability, FMP has built a strong reputation as a trusted partner in both agricultural and industrial markets. Our extensive portfolio includes custom-engineered gearboxes for lawn mowers, PTO shafts, and a wide range of critical components, each meticulously crafted to meet the specific needs of various applications.

At FMP, we understand that every client faces unique challenges. This drives our commitment to providing tailored solutions, whether for individual components or fully integrated systems. By collaborating closely with our clients, we ensure that each solution not only meets their precise requirements but also enhances performance and maximizes value. Our dedication to providing prompt, professional responses and expert guidance guarantees that every inquiry is addressed with precision, leading to the best possible outcomes.

Clear and continuous communication is fundamental to our approach throughout the entire product development cycle. Our dedicated team works directly with clients to gain a thorough understanding of their needs, offering valuable insights and recommendations to ensure optimal results. Whether designing cutting-edge products or fulfilling routine orders, FMP is committed to delivering high-quality, precision-engineered solutions on time, every time. Our mission is to consistently exceed client expectations, providing exceptional service and delivering outstanding results with every project.

Quality is the cornerstone of FMP’s operations. We adhere to the highest manufacturing standards and implement rigorous quality control processes to ensure that each product not only meets but often surpasses industry benchmarks. This commitment to excellence, combined with our core values of integrity, teamwork, and perseverance, has allowed us to establish long-lasting, trust-based relationships with clients across nearly 30 countries worldwide.

At FMP, we are eager to foster global partnerships by offering expert advice and customized solutions that address the evolving needs of our clients. We are dedicated to building long-term, mutually beneficial relationships that contribute to the success of every project. Whether you require innovative solutions for a new venture or ongoing support for an existing system, FMP is here to help you overcome technical challenges and ensure your continued success.

Author: CX