Product Specification

| Product Description |

Rotary Mower Gearboxes – Replacement of Comer Gearbox LF-211J

|

|---|---|

| Product details |

|

| Application range |

Mowers

|

| Consists of |

|

| Contains oil |

No

|

| Max. oil capacity |

0.8 l

|

| Max. oil change interval |

500 h

|

| Oil SAE viscosity grade |

80W-90

|

| Housing material |

Cast iron GGG40

|

| Weight |

14 kg

|

| Gear arrangement Increasing |

3

|

| Input power kW / HP Increasing |

14.7 / 20 kW/HP

|

| Input shaft Increasing |

X

|

| Output Torque DaNm Increasing |

8.9 daNm

|

| Ratio Increasing |

1: 2.83

|

| Ratio Reducing |

2.83 : 1

|

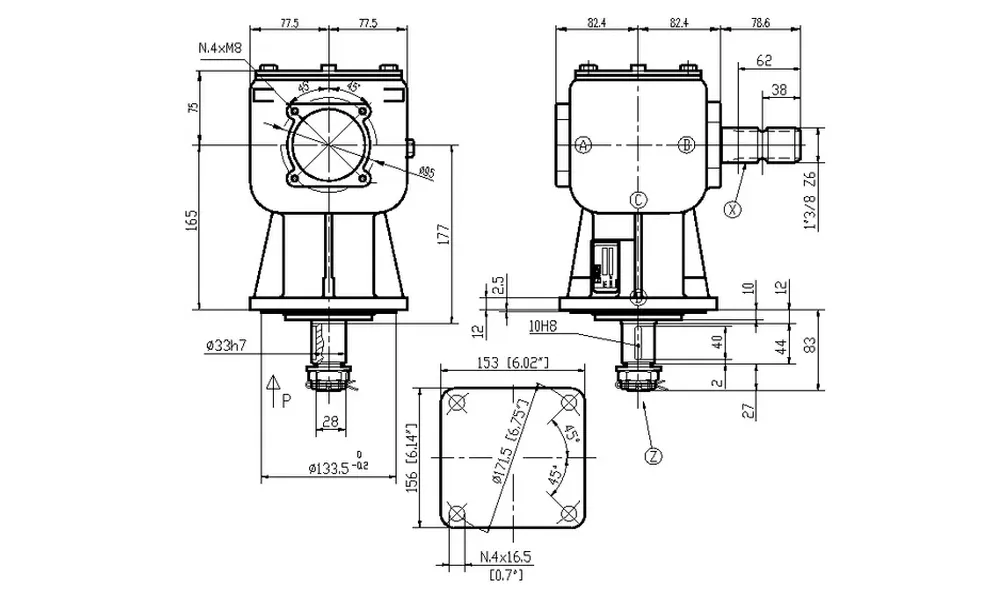

| Shaft X |

1 3/8″ (6)

|

| Shaft Z |

33 h7

|

Features of LF-211J Rotary Mower Gearbox

The LF-211J is a high-performance rotary mower gearbox designed for agricultural and industrial applications, providing reliable and efficient power transmission for rotary mowers. Key features include:

- Gear Ratio: The gearbox has a gear ratio of 1:2.83, meaning the output speed is approximately 2.83 times the input speed.

- Power Capacity: It can handle a maximum input power of 14.7 kW (20 HP) and delivers a maximum output torque of 8.9 daNm.

- Construction: The housing is made from cast iron GGG40, known for its durability and strength, ensuring longevity and resistance to wear.

- Oil Capacity and Maintenance: The gearbox has a maximum oil capacity of 0.8 liters and uses SAE 80W-90 gear oil. It’s recommended to perform the first oil change after 50-70 operating hours, followed by subsequent changes every 500-700 hours or at least once a year.

- Weight: The unit weighs approximately 14 kg, making it relatively easy to handle and install.

- Shaft Specifications: The input shaft is designed to accommodate a 1 3/8″ (6-spline) connection, while the output shaft has a diameter of 33 mm, ensuring compatibility with standard rotary mower components.

These features make the LF-211J gearbox a reliable choice for enhancing the performance and efficiency of rotary mowers in various agricultural settings.

How to Remove a Rotary Mower Gearbox

Removing a rotary mower gearbox is a straightforward process if done carefully and systematically. Follow these steps to ensure safety and efficiency:

1. Disconnect the Power Source

Before starting, disconnect the mower’s power source to avoid any accidental operation. This may include turning off the engine, unplugging the power cord, or disconnecting the battery.

2. Remove the Cutting Blades

Detach the cutting blades from the mower deck to gain access to the gearbox. Ensure the mower is stable and use appropriate tools to safely remove the blades.

3. Loosen the Gearbox Mounting Bolts

Identify the mounting bolts securing the gearbox to the mower deck. Using a wrench or socket, loosen and remove these bolts.

4. Detach the Input and Output Shafts

Disconnect the input and output shafts connected to the gearbox. You may need to remove couplings, pins, or other attachments. Take note of how the shafts are connected for easier reassembly.

5. Remove the Gearbox from the Deck

Carefully lift the gearbox off the mower deck. Depending on the size and weight of the gearbox, assistance from another person may be necessary to ensure safe handling.

6. Inspect the Gearbox

Examine the gearbox for signs of wear or damage, such as worn gears, damaged seals, or faulty bearings. This step is crucial for determining whether the gearbox can be repaired or needs replacement.

7. Repair or Replace the Gearbox

If the gearbox shows damage, follow the manufacturer’s guidelines for repair or replacement. Ensure all components are in proper working condition before reinstalling.

8. Reinstall the Gearbox

To reinstall, follow the removal steps in reverse order:

- Position the gearbox on the mower deck.

- Secure the mounting bolts, tightening them to the manufacturer’s recommended torque specifications.

- Reconnect the input and output shafts, ensuring all couplings and attachments are properly aligned.

- Reinstall the cutting blades securely.

9. Test the Mower

After reinstalling, test the mower to ensure the gearbox operates smoothly and there are no unusual noises or vibrations.

Safety Tips

- Always wear protective gloves and safety glasses during the process.

- Use stable supports to prevent the mower from tipping over.

- Follow the specific instructions in your mower’s user manual to ensure compatibility and safety.

By carefully following these steps and adhering to safety precautions, you can successfully remove, inspect, and replace or repair the rotary mower gearbox as needed.

About FMP

FMP is a prominent company based in Italy, specializing in the research, development, and manufacturing of various gearboxes, reducers, and engineering machinery. The company is also committed to nurturing technical talent to drive innovation and excellence in its field. FMP’s product portfolio includes spiral bevel gearboxes, spur gearboxes, worm gearboxes, cylindrical gearboxes, as well as high-pressure cast valve bodies and housings.

Extensive Applications

FMP’s products are widely used across diverse applications, including:

- Agricultural machinery such as rotary mowers, snow sweepers, fertilizer spreaders, and grain conveyors.

- Industrial equipment, oil extraction machinery, marine industrial devices, and hydraulic components for engineering projects.

Advanced Manufacturing and Technology

FMP takes pride in its robust technical and R&D capabilities, ensuring reliable and high-quality products that meet the demands of modern industries. The company adopts a meticulous and sophisticated manufacturing process, including:

- Product Design: Developing customized specifications, materials, and dimensions to suit client needs.

- Material Preparation: Utilizing premium materials such as cast iron or aluminum alloys.

- Precision Machining: Employing advanced turning, milling, and other machining techniques to produce key components like gears and housings.

- Assembly: Assembling gears, bearings, and shafts into the housing with precision alignment, calibration, and appropriate lubrication.

- Process Treatment: Conducting heat treatment to enhance strength and wear resistance.

- Surface Treatment: Applying polishing, powder coating, and other surface treatments for enhanced appearance and corrosion resistance.

- Quality Control: Implementing rigorous inspections and tests for dimensions, accuracy, noise, and vibration to ensure stability, safety, and consistent quality.

Industry Reputation

FMP’s dedication to quality, innovation, and customer satisfaction has earned it a distinguished reputation in the manufacturing industry. The company adheres to a unique business philosophy that emphasizes reliability, craftsmanship, and excellence.

We welcome inquiries and collaboration opportunities from clients and partners worldwide. Please feel free to contact us via phone or email for more information about our products and services.

Author: CX